Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

nanoindentation, microscratching <strong>and</strong> nanowear behavior of solid surfaces <strong>and</strong> thin<br />

films [5, 36–38]. In general, adhesive wear mechanism still operates for metallic<br />

materials under light loads. L<strong>and</strong>man et al. used MD simulation <strong>and</strong> AFM to study<br />

the atomistic mechanism of contact formation between a hard nickel tip <strong>and</strong> soft<br />

gold sample [39]. Indentation of a gold surface by advancing a nickel tip resulted in<br />

the adhesion of gold atoms to the nickel tip <strong>and</strong> formation of a connective neck of<br />

atoms.<br />

Interestingly, MD simulations show that CNTs can slide <strong>and</strong> roll against each other<br />

under the application of a shear force [40, 41]. The rolling of CNTs at the atomic level<br />

on the graphite surface has been verified experimentally by Falvo et al. using AFM [42].<br />

They reported that rolling can occur only when both the nanotube <strong>and</strong> the underlying<br />

graphite have long-range order. Thus, a nanotube has preferred orientations on the<br />

graphite surface <strong>and</strong> rolling takes place when it is in atomic scale registry with the<br />

surface. This behavior is somewhat similar to the rolling of fullerenes that act like<br />

nanoscale ball bearings <strong>and</strong> solid lubricants [43, 44]. Despite the widespread use of<br />

AFM for characterizing the nanowear of metallic materials, little work has been done<br />

on nanowear of metal-CNT composites.<br />

Up till now, there appears to be no reported work on the nanowear behavior of<br />

metal-CNT nanocomposites in the literature. Only wear properties of metal-CNT<br />

nanocomposites at macro-levels have been reported. Zhang <strong>and</strong> coworkers [Chap. 2,<br />

Ref. 28] investigated the dry friction <strong>and</strong> wear behaviors of Al-Mg/MWNT nanocomposites<br />

using a pin-on-disk test under a load of 30 N. The nanocomposites were<br />

prepared by liquid metallurgy route in which molten Al was infiltrated into CNT-Al-<br />

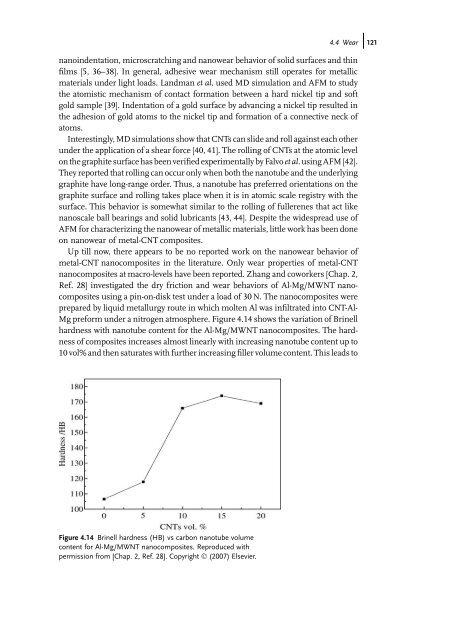

Mg preform under a nitrogen atmosphere. Figure 4.14 shows the variation of Brinell<br />

hardness with nanotube content for the Al-Mg/MWNT nanocomposites. The hardness<br />

of composites increases almost linearly with increasing nanotube content up to<br />

10 vol% <strong>and</strong> then saturates with further increasing filler volume content. This leads to<br />

Figure 4.14 Brinell hardness (HB) vs carbon nanotube volume<br />

content for Al-Mg/MWNT nanocomposites. Reproduced with<br />

permission from [Chap. 2, Ref. 28]. Copyright Ó (2007) Elsevier.<br />

4.4 Wearj121