Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

170j 6 Physical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Ceramic</strong> Nanocomposites<br />

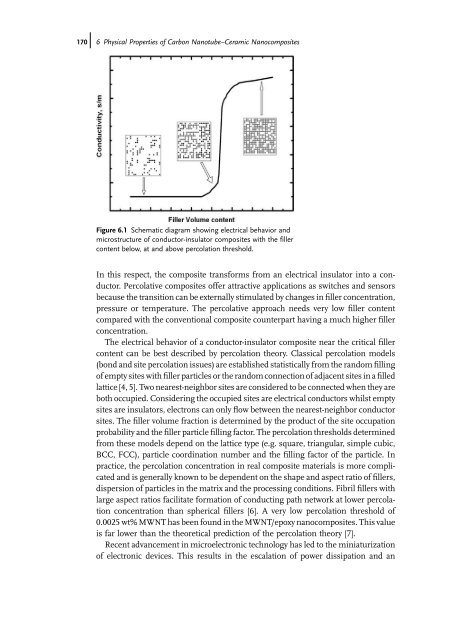

Figure 6.1 Schematic diagram showing electrical behavior <strong>and</strong><br />

microstructure of conductor-insulator composites with the filler<br />

content below, at <strong>and</strong> above percolation threshold.<br />

In this respect, the composite transforms from an electrical insulator into a conductor.<br />

Percolative composites offer attractive applications as switches <strong>and</strong> sensors<br />

because the transition can be externally stimulated by changes in filler concentration,<br />

pressure or temperature. The percolative approach needs very low filler content<br />

compared with the conventional composite counterpart having a much higher filler<br />

concentration.<br />

The electrical behavior of a conductor-insulator composite near the critical filler<br />

content can be best described by percolation theory. Classical percolation models<br />

(bond <strong>and</strong> site percolation issues) are established statistically from the r<strong>and</strong>om filling<br />

of empty sites with filler particles or the r<strong>and</strong>om connection of adjacent sites in a filled<br />

lattice [4, 5]. Two nearest-neighbor sites are considered to be connected when they are<br />

both occupied. Considering the occupied sites are electrical conductors whilst empty<br />

sites are insulators, electrons can only flow between the nearest-neighbor conductor<br />

sites. The filler volume fraction is determined by the product of the site occupation<br />

probability <strong>and</strong> the filler particle filling factor. The percolation thresholds determined<br />

from these models depend on the lattice type (e.g. square, triangular, simple cubic,<br />

BCC, FCC), particle coordination number <strong>and</strong> the filling factor of the particle. In<br />

practice, the percolation concentration in real composite materials is more complicated<br />

<strong>and</strong> is generally known to be dependent on the shape <strong>and</strong> aspect ratio of fillers,<br />

dispersion of particles in the matrix <strong>and</strong> the processing conditions. Fibril fillers with<br />

large aspect ratios facilitate formation of conducting path network at lower percolation<br />

concentration than spherical fillers [6]. A very low percolation threshold of<br />

0.0025 wt% MWNT has been found in the MWNT/epoxy nanocomposites. This value<br />

is far lower than the theoretical prediction of the percolation theory [7].<br />

Recent advancement in microelectronic technology has led to the miniaturization<br />

of electronic devices. This results in the escalation of power dissipation <strong>and</strong> an