Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

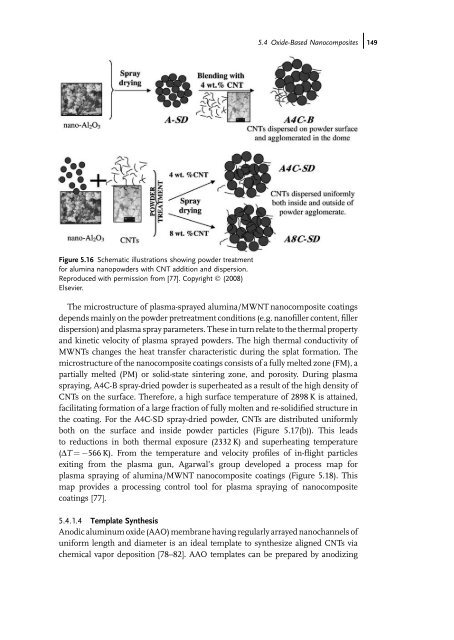

Figure 5.16 Schematic illustrations showing powder treatment<br />

for alumina nanopowders with CNT addition <strong>and</strong> dispersion.<br />

Reproduced with permission from [77]. Copyright Ó (2008)<br />

Elsevier.<br />

5.4 Oxide-Based Nanocompositesj149<br />

The microstructure of plasma-sprayed alumina/MWNT nanocomposite coatings<br />

depends mainly on the powder pretreatment conditions (e.g. nanofiller content, filler<br />

dispersion) <strong>and</strong> plasma spray parameters. These in turn relate to the thermal property<br />

<strong>and</strong> kinetic velocity of plasma sprayed powders. The high thermal conductivity of<br />

MWNTs changes the heat transfer characteristic during the splat formation. The<br />

microstructure of the nanocomposite coatings consists of a fully melted zone (FM), a<br />

partially melted (PM) or solid-state sintering zone, <strong>and</strong> porosity. During plasma<br />

spraying, A4C-B spray-dried powder is superheated as a result of the high density of<br />

CNTs on the surface. Therefore, a high surface temperature of 2898 K is attained,<br />

facilitating formation of a large fraction of fully molten <strong>and</strong> re-solidified structure in<br />

the coating. For the A4C-SD spray-dried powder, CNTs are distributed uniformly<br />

both on the surface <strong>and</strong> inside powder particles (Figure 5.17(b)). This leads<br />

to reductions in both thermal exposure (2332 K) <strong>and</strong> superheating temperature<br />

(DT ¼ 566 K). From the temperature <strong>and</strong> velocity profiles of in-flight particles<br />

exiting from the plasma gun, Agarwal s group developed a process map for<br />

plasma spraying of alumina/MWNT nanocomposite coatings (Figure 5.18). This<br />

map provides a processing control tool for plasma spraying of nanocomposite<br />

coatings [77].<br />

5.4.1.4 Template Synthesis<br />

Anodic aluminum oxide (AAO) membrane having regularly arrayed nanochannels of<br />

uniform length <strong>and</strong> diameter is an ideal template to synthesize aligned CNTs via<br />

chemical vapor deposition [78–82]. AAO templates can be prepared by anodizing