Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

194j 7 Mechanical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Ceramic</strong> Nanocomposites<br />

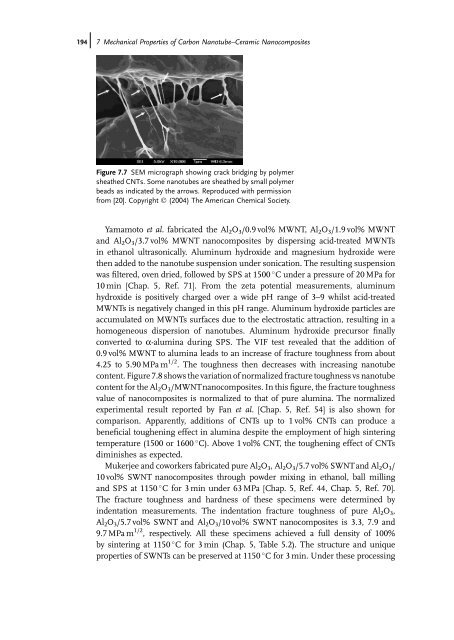

Figure 7.7 SEM micrograph showing crack bridging by polymer<br />

sheathed CNTs. Some nanotubes are sheathed by small polymer<br />

beads as indicated by the arrows. Reproduced with permission<br />

from [20]. Copyright Ó (2004) The American Chemical Society.<br />

Yamamoto et al. fabricated the Al2O3/0.9 vol% MWNT, Al2O3/1.9 vol% MWNT<br />

<strong>and</strong> Al2O3/3.7 vol% MWNT nanocomposites by dispersing acid-treated MWNTs<br />

in ethanol ultrasonically. Aluminum hydroxide <strong>and</strong> magnesium hydroxide were<br />

then added to the nanotube suspension under sonication. The resulting suspension<br />

was filtered, oven dried, followed by SPS at 1500 C under a pressure of 20 MPa for<br />

10 min [Chap. 5, Ref. 71]. From the zeta potential measurements, aluminum<br />

hydroxide is positively charged over a wide pH range of 3–9 whilst acid-treated<br />

MWNTs is negatively changed in this pH range. Aluminum hydroxide particles are<br />

accumulated on MWNTs surfaces due to the electrostatic attraction, resulting in a<br />

homogeneous dispersion of nanotubes. Aluminum hydroxide precursor finally<br />

converted to a-alumina during SPS. The VIF test revealed that the addition of<br />

0.9 vol% MWNT to alumina leads to an increase of fracture toughness from about<br />

4.25 to 5.90 MPa m 1/2 . The toughness then decreases with increasing nanotube<br />

content. Figure 7.8 shows the variation of normalized fracture toughness vs nanotube<br />

content for the Al2O3/MWNTnanocomposites. In this figure, the fracture toughness<br />

value of nanocomposites is normalized to that of pure alumina. The normalized<br />

experimental result reported by Fan et al. [Chap. 5, Ref. 54] is also shown for<br />

comparison. Apparently, additions of CNTs up to 1 vol% CNTs can produce a<br />

beneficial toughening effect in alumina despite the employment of high sintering<br />

temperature (1500 or 1600 C). Above 1 vol% CNT, the toughening effect of CNTs<br />

diminishes as expected.<br />

Mukerjee <strong>and</strong> coworkers fabricated pure Al 2O 3,Al 2O 3/5.7 vol% SWNT<strong>and</strong> Al 2O 3/<br />

10 vol% SWNT nanocomposites through powder mixing in ethanol, ball milling<br />

<strong>and</strong> SPS at 1150 C for 3 min under 63 MPa [Chap. 5, Ref. 44, Chap. 5, Ref. 70].<br />

The fracture toughness <strong>and</strong> hardness of these specimens were determined by<br />

indentation measurements. The indentation fracture toughness of pure Al2O3,<br />

Al2O3/5.7 vol% SWNT <strong>and</strong> Al2O3/10 vol% SWNT nanocomposites is 3.3, 7.9 <strong>and</strong><br />

9.7 MPa m 1/2 , respectively. All these specimens achieved a full density of 100%<br />

by sintering at 1150 C for 3 min (Chap. 5, Table 5.2). The structure <strong>and</strong> unique<br />

properties of SWNTs can be preserved at 1150 C for 3 min. Under these processing