Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

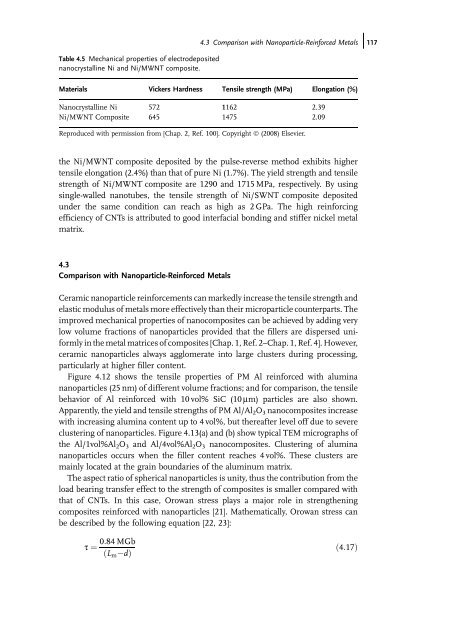

Table 4.5 Mechanical properties of electrodeposited<br />

nanocrystalline Ni <strong>and</strong> Ni/MWNT composite.<br />

the Ni/MWNT composite deposited by the pulse-reverse method exhibits higher<br />

tensile elongation (2.4%) than that of pure Ni (1.7%). The yield strength <strong>and</strong> tensile<br />

strength of Ni/MWNT composite are 1290 <strong>and</strong> 1715 MPa, respectively. By using<br />

single-walled nanotubes, the tensile strength of Ni/SWNT composite deposited<br />

under the same condition can reach as high as 2 GPa. The high reinforcing<br />

efficiency of CNTs is attributed to good interfacial bonding <strong>and</strong> stiffer nickel metal<br />

matrix.<br />

4.3<br />

Comparison with Nanoparticle-<strong>Reinforced</strong> <strong>Metal</strong>s<br />

<strong>Ceramic</strong> nanoparticle reinforcements can markedly increase the tensile strength <strong>and</strong><br />

elastic modulus of metals more effectively than their microparticle counterparts. The<br />

improved mechanical properties of nanocomposites can be achieved by adding very<br />

low volume fractions of nanoparticles provided that the fillers are dispersed uniformly<br />

in the metal matrices of composites [Chap. 1, Ref. 2–Chap. 1, Ref. 4]. However,<br />

ceramic nanoparticles always agglomerate into large clusters during processing,<br />

particularly at higher filler content.<br />

Figure 4.12 shows the tensile properties of PM Al reinforced with alumina<br />

nanoparticles (25 nm) of different volume fractions; <strong>and</strong> for comparison, the tensile<br />

behavior of Al reinforced with 10 vol% SiC (10 mm) particles are also shown.<br />

Apparently, the yield <strong>and</strong> tensile strengths of PM Al/Al2O3 nanocomposites increase<br />

with increasing alumina content up to 4 vol%, but thereafter level off due to severe<br />

clustering of nanoparticles. Figure 4.13(a) <strong>and</strong> (b) show typical TEM micrographs of<br />

the Al/1vol%Al2O3 <strong>and</strong> Al/4vol%Al2O3 nanocomposites. Clustering of alumina<br />

nanoparticles occurs when the filler content reaches 4 vol%. These clusters are<br />

mainly located at the grain boundaries of the aluminum matrix.<br />

The aspect ratio of spherical nanoparticles is unity, thus the contribution from the<br />

load bearing transfer effect to the strength of composites is smaller compared with<br />

that of CNTs. In this case, Orowan stress plays a major role in strengthening<br />

composites reinforced with nanoparticles [21]. Mathematically, Orowan stress can<br />

be described by the following equation [22, 23]:<br />

t ¼<br />

0:84 MGb<br />

ðLm dÞ<br />

4.3 Comparison with Nanoparticle-<strong>Reinforced</strong> <strong>Metal</strong>sj117<br />

Materials Vickers Hardness Tensile strength (MPa) Elongation (%)<br />

Nanocrystalline Ni 572 1162 2.39<br />

Ni/MWNT Composite 645 1475 2.09<br />

Reproduced with permission from [Chap. 2, Ref. 100]. Copyright Ó (2008) Elsevier.<br />

ð4:17Þ