Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

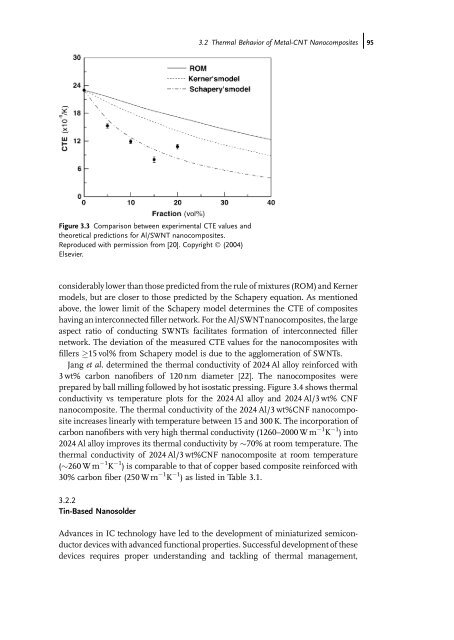

Figure 3.3 Comparison between experimental CTE values <strong>and</strong><br />

theoretical predictions for Al/SWNT nanocomposites.<br />

Reproduced with permission from [20]. Copyright Ó (2004)<br />

Elsevier.<br />

considerably lower than those predicted from the rule of mixtures (ROM) <strong>and</strong> Kerner<br />

models, but are closer to those predicted by the Schapery equation. As mentioned<br />

above, the lower limit of the Schapery model determines the CTE of composites<br />

having an interconnected filler network. For the Al/SWNTnanocomposites, the large<br />

aspect ratio of conducting SWNTs facilitates formation of interconnected filler<br />

network. The deviation of the measured CTE values for the nanocomposites with<br />

fillers 15 vol% from Schapery model is due to the agglomeration of SWNTs.<br />

Jang et al. determined the thermal conductivity of 2024 Al alloy reinforced with<br />

3 wt% carbon nanofibers of 120 nm diameter [22]. The nanocomposites were<br />

prepared by ball milling followed by hot isostatic pressing. Figure 3.4 shows thermal<br />

conductivity vs temperature plots for the 2024 Al alloy <strong>and</strong> 2024 Al/3 wt% CNF<br />

nanocomposite. The thermal conductivity of the 2024 Al/3 wt%CNF nanocomposite<br />

increases linearly with temperature between 15 <strong>and</strong> 300 K. The incorporation of<br />

carbon nanofibers with very high thermal conductivity (1260–2000 W m 1 K 1 ) into<br />

2024 Al alloy improves its thermal conductivity by 70% at room temperature. The<br />

thermal conductivity of 2024 Al/3 wt%CNF nanocomposite at room temperature<br />

( 260 W m 1 K 1 ) is comparable to that of copper based composite reinforced with<br />

30% carbon fiber (250 W m 1 K 1 ) as listed in Table 3.1.<br />

3.2.2<br />

Tin-Based Nanosolder<br />

3.2 Thermal Behavior of <strong>Metal</strong>-CNT Nanocompositesj95<br />

Advances in IC technology have led to the development of miniaturized semiconductor<br />

devices with advanced functional properties. Successful development of these<br />

devices requires proper underst<strong>and</strong>ing <strong>and</strong> tackling of thermal management,