Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

coating material, the plasma gun <strong>and</strong> component are enclosed in a low pressure<br />

chamber containing an inert atmosphere. Plasma spraying offers improved coating<br />

adhesion <strong>and</strong> higher density of coating due to its high spraying velocity. The HVOF<br />

method employs a combustion flame of compressed fuel gas <strong>and</strong> oxygen to heat the<br />

coating material rapidly in an internal combustion at 3000–6000 C<strong>and</strong>accelerate<br />

the coating material to high velocities ( 700–1800 ms 1 ) (Figure 2.1(b)). Molten<br />

splats encounter extremely high cooling rates during solidification, that is,<br />

10 6 –10 8 Ks 1 for PSF <strong>and</strong> 10 3 –10 5 for HVOF. Thermal spray coatings generally<br />

contain pores <strong>and</strong> consolidation treatment such as sintering, spark plasma sintering,<br />

hot pressing or laser irradiation is needed to remove porosities [22].<br />

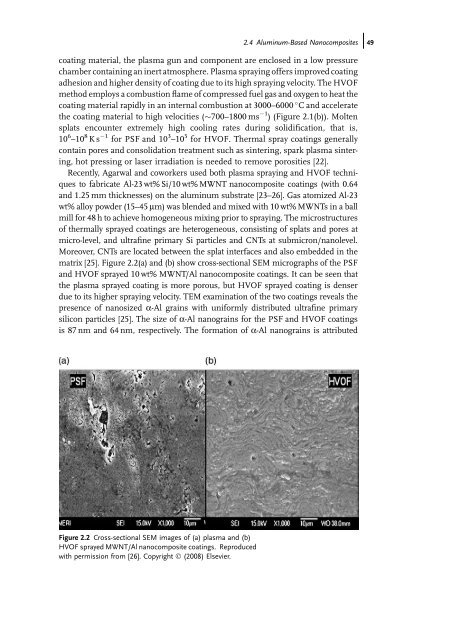

Recently, Agarwal <strong>and</strong> coworkers used both plasma spraying <strong>and</strong> HVOF techniques<br />

to fabricate Al-23 wt% Si/10 wt% MWNT nanocomposite coatings (with 0.64<br />

<strong>and</strong> 1.25 mm thicknesses) on the aluminum substrate [23–26]. Gas atomized Al-23<br />

wt% alloy powder (15–45 mm) was blended <strong>and</strong> mixed with 10 wt% MWNTs in a ball<br />

mill for 48 h to achieve homogeneous mixing prior to spraying. The microstructures<br />

of thermally sprayed coatings are heterogeneous, consisting of splats <strong>and</strong> pores at<br />

micro-level, <strong>and</strong> ultrafine primary Si particles <strong>and</strong> CNTs at submicron/nanolevel.<br />

Moreover, CNTs are located between the splat interfaces <strong>and</strong> also embedded in the<br />

matrix [25]. Figure 2.2(a) <strong>and</strong> (b) show cross-sectional SEM micrographs of the PSF<br />

<strong>and</strong> HVOF sprayed 10 wt% MWNT/Al nanocomposite coatings. It can be seen that<br />

the plasma sprayed coating is more porous, but HVOF sprayed coating is denser<br />

due to its higher spraying velocity. TEM examination of the two coatings reveals the<br />

presence of nanosized a-Al grains with uniformly distributed ultrafine primary<br />

silicon particles [25]. The size of a-Al nanograins for the PSF <strong>and</strong> HVOF coatings<br />

is 87 nm <strong>and</strong> 64 nm, respectively. The formation of a-Al nanograins is attributed<br />

Figure 2.2 Cross-sectional SEM images of (a) plasma <strong>and</strong> (b)<br />

HVOF sprayed MWNT/Al nanocomposite coatings. Reproduced<br />

with permission from [26]. Copyright Ó (2008) Elsevier.<br />

2.4 Aluminum-Based Nanocompositesj49