Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

50j 2 <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Metal</strong> Nanocomposites<br />

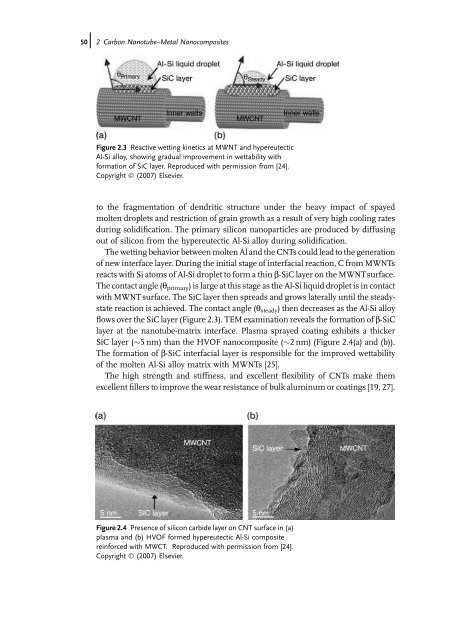

Figure 2.3 Reactive wetting kinetics at MWNT <strong>and</strong> hypereutectic<br />

Al-Si alloy, showing gradual improvement in wettability with<br />

formation of SiC layer. Reproduced with permission from [24].<br />

Copyright Ó (2007) Elsevier.<br />

to the fragmentation of dendritic structure under the heavy impact of spayed<br />

molten droplets <strong>and</strong> restriction of grain growth as a result of very high cooling rates<br />

during solidification. The primary silicon nanoparticles are produced by diffusing<br />

out of silicon from the hypereutectic Al-Si alloy during solidification.<br />

The wetting behavior between molten Al <strong>and</strong> the CNTs could lead to the generation<br />

of new interface layer. During the initial stage of interfacial reaction, C from MWNTs<br />

reacts with Si atoms of Al-Si droplet to form a thin b-SiC layer on the MWNTsurface.<br />

The contact angle (q primary) is large at this stage as the Al-Si liquid droplet is in contact<br />

with MWNTsurface. The SiC layer then spreads <strong>and</strong> grows laterally until the steadystate<br />

reaction is achieved. The contact angle (qsteady) then decreases as the Al-Si alloy<br />

flows over the SiC layer (Figure 2.3). TEM examination reveals the formation of b-SiC<br />

layer at the nanotube-matrix interface. Plasma sprayed coating exhibits a thicker<br />

SiC layer ( 5 nm) than the HVOF nanocomposite ( 2 nm) (Figure 2.4(a) <strong>and</strong> (b)).<br />

The formation of b-SiC interfacial layer is responsible for the improved wettability<br />

of the molten Al-Si alloy matrix with MWNTs [25].<br />

The high strength <strong>and</strong> stiffness, <strong>and</strong> excellent flexibility of CNTs make them<br />

excellent fillers to improve the wear resistance of bulk aluminum or coatings [19, 27].<br />

Figure 2.4 Presence of silicon carbide layer on CNT surface in (a)<br />

plasma <strong>and</strong> (b) HVOF formed hypereutectic Al-Si composite<br />

reinforced with MWCT. Reproduced with permission from [24].<br />

Copyright Ó (2007) Elsevier.