Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

212j 7 Mechanical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Ceramic</strong> Nanocomposites<br />

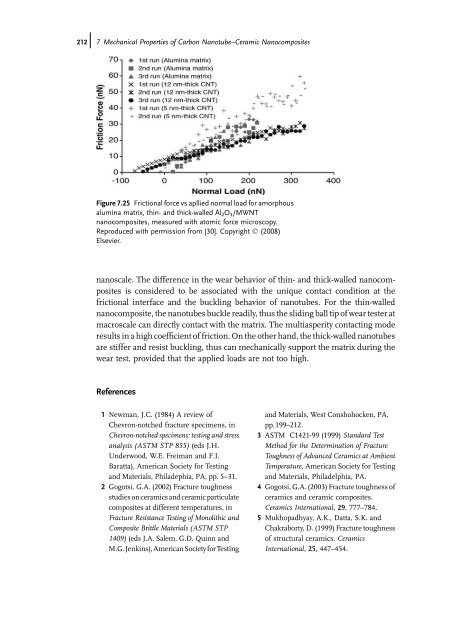

Figure 7.25 Frictional force vs apllied normal load for amorphous<br />

alumina matrix, thin- <strong>and</strong> thick-walled Al2O3/MWNT<br />

nanocomposites, measured with atomic force microscopy.<br />

Reproduced with permission from [30]. Copyright Ó (2008)<br />

Elsevier.<br />

nanoscale. The difference in the wear behavior of thin- <strong>and</strong> thick-walled nanocomposites<br />

is considered to be associated with the unique contact condition at the<br />

frictional interface <strong>and</strong> the buckling behavior of nanotubes. For the thin-walled<br />

nanocomposite, the nanotubes buckle readily, thus the sliding ball tip of wear tester at<br />

macroscale can directly contact with the matrix. The multiasperity contacting mode<br />

results in a high coefficient of friction. On the other h<strong>and</strong>, the thick-walled nanotubes<br />

are stiffer <strong>and</strong> resist buckling, thus can mechanically support the matrix during the<br />

wear test, provided that the applied loads are not too high.<br />

References<br />

1 Newman, J.C. (1984) A review of<br />

Chevron-notched fracture specimens, in<br />

Chevron-notched specimens: testing <strong>and</strong> stress<br />

analysis (ASTM STP 855) (eds J.H.<br />

Underwood, W.E. Freiman <strong>and</strong> F.I.<br />

Baratta), American Society for Testing<br />

<strong>and</strong> Materials, Philadephia, PA, pp. 5–31.<br />

2 Gogotsi, G.A. (2002) Fracture toughness<br />

studiesonceramics <strong>and</strong> ceramic particulate<br />

composites at different temperatures, in<br />

Fracture Resistance Testing of Monolithic <strong>and</strong><br />

Composite Brittle Materials (ASTM STP<br />

1409) (eds J.A. Salem, G.D. Quinn <strong>and</strong><br />

M.G.Jenkins),AmericanSocietyforTesting<br />

<strong>and</strong> Materials, West Conshohocken, PA,<br />

pp.199–212.<br />

3 ASTM C1421-99 (1999) St<strong>and</strong>ard Test<br />

Method for the Determination of Fracture<br />

Toughness of Advanced <strong>Ceramic</strong>s at Ambient<br />

Temperature, American Society for Testing<br />

<strong>and</strong> Materials, Philadelphia, PA.<br />

4 Gogotsi, G.A. (2003) Fracture toughness of<br />

ceramics <strong>and</strong> ceramic composites.<br />

<strong>Ceramic</strong>s International, 29, 777–784.<br />

5 Mukhopadhyay, A.K., Datta, S.K. <strong>and</strong><br />

Chakraborty, D. (1999) Fracture toughness<br />

of structural ceramics. <strong>Ceramic</strong>s<br />

International, 25, 447–454.