Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

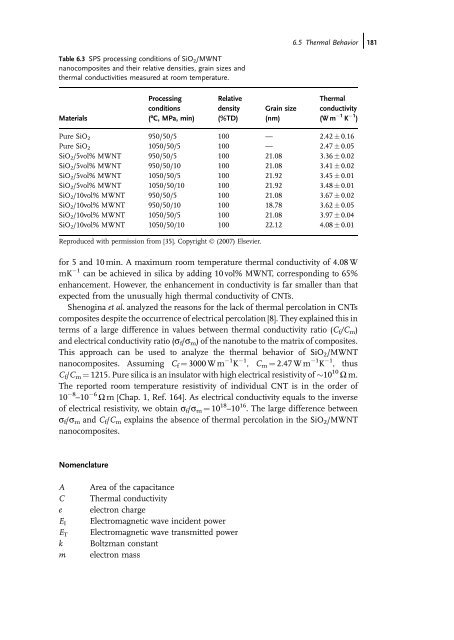

Table 6.3 SPS processing conditions of SiO2/MWNT<br />

nanocomposites <strong>and</strong> their relative densities, grain sizes <strong>and</strong><br />

thermal conductivities measured at room temperature.<br />

Materials<br />

for 5 <strong>and</strong> 10 min. A maximum room temperature thermal conductivity of 4.08 W<br />

mK 1 can be achieved in silica by adding 10 vol% MWNT, corresponding to 65%<br />

enhancement. However, the enhancement in conductivity is far smaller than that<br />

expected from the unusually high thermal conductivity of CNTs.<br />

Shenogina et al. analyzed the reasons for the lack of thermal percolation in CNTs<br />

composites despite the occurrence of electrical percolation [8]. They explained this in<br />

terms of a large difference in values between thermal conductivity ratio (Cf/Cm)<br />

<strong>and</strong> electrical conductivity ratio (sf/sm) of the nanotube to the matrix of composites.<br />

This approach can be used to analyze the thermal behavior of SiO2/MWNT<br />

nanocomposites. Assuming Cf ¼ 3000 W m 1 K 1 , Cm ¼ 2.47 W m 1 K 1 , thus<br />

Cf/Cm ¼ 1215. Pure silica is an insulator with high electrical resistivity of 10 10 W m.<br />

The reported room temperature resistivity of individual CNT is in the order of<br />

10 8 –10 6 W m [Chap. 1, Ref. 164]. As electrical conductivity equals to the inverse<br />

of electrical resistivity, we obtain sf/sm ¼ 10 18 –10 16 . The large difference between<br />

sf/sm <strong>and</strong> Cf/Cm explains the absence of thermal percolation in the SiO2/MWNT<br />

nanocomposites.<br />

Nomenclature<br />

Processing<br />

conditions<br />

(ºC, MPa, min)<br />

Relative<br />

density<br />

(%TD)<br />

A Area of the capacitance<br />

C Thermal conductivity<br />

e electron charge<br />

EI Electromagnetic wave incident power<br />

ET Electromagnetic wave transmitted power<br />

k Boltzman constant<br />

m electron mass<br />

Grain size<br />

(nm)<br />

Thermal<br />

conductivity<br />

(W m 1 K 1 )<br />

Pure SiO2 950/50/5 100 — 2.42 0.16<br />

Pure SiO 2 1050/50/5 100 — 2.47 0.05<br />

SiO2/5vol% MWNT 950/50/5 100 21.08 3.36 0.02<br />

SiO 2/5vol% MWNT 950/50/10 100 21.08 3.41 0.02<br />

SiO2/5vol% MWNT 1050/50/5 100 21.92 3.45 0.01<br />

SiO 2/5vol% MWNT 1050/50/10 100 21.92 3.48 0.01<br />

SiO2/10vol% MWNT 950/50/5 100 21.08 3.67 0.02<br />

SiO 2/10vol% MWNT 950/50/10 100 18.78 3.62 0.05<br />

SiO2/10vol% MWNT 1050/50/5 100 21.08 3.97 0.04<br />

SiO2/10vol% MWNT 1050/50/10 100 22.12 4.08 0.01<br />

Reproduced with permission from [35]. Copyright Ó (2007) Elsevier.<br />

6.5 Thermal Behaviorj181