Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

has also been reported by other researchers for the micro-nano ceramic composites<br />

[25–28]. The switch from intergranular to transgranular failure is a good<br />

indicator for the strength <strong>and</strong> toughness improvements in ceramic nanocomposites.<br />

Second-phase nanoparticles enhance grain boundary properties of ceramics by<br />

inducing residual stress as a result of thermal expansion mismatch between the<br />

matrix <strong>and</strong> particles. This internal stress causes an advancing crack to propagate in a<br />

tortuous manner rather than a catastrophic straight path. Moreover, second-phase<br />

nanoparticle additions also lead to the grain refinement of the ceramic matrix [37].<br />

Reducing grain size promotes the mechanical strength of crystalline materials<br />

according to the Hall–Petch relation. In some cases, second-phase nanoparticles<br />

also yield elongation of matrix grains. The elongated matrix grains with high aspect<br />

ratio increase the fracture toughness by dissipating the fracture energy through crack<br />

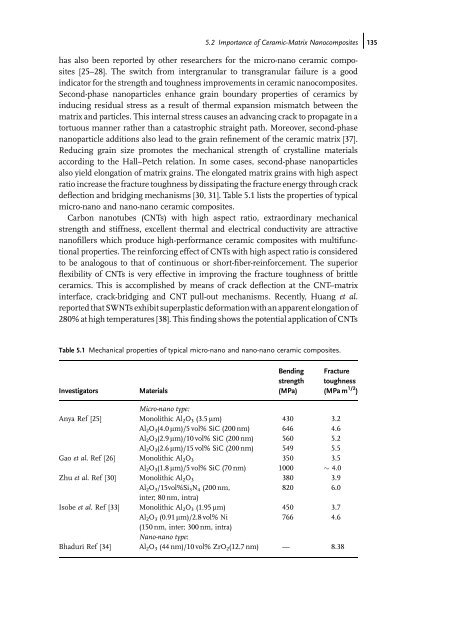

deflection <strong>and</strong> bridging mechanisms [30, 31]. Table 5.1 lists the properties of typical<br />

micro-nano <strong>and</strong> nano-nano ceramic composites.<br />

<strong>Carbon</strong> nanotubes (CNTs) with high aspect ratio, extraordinary mechanical<br />

strength <strong>and</strong> stiffness, excellent thermal <strong>and</strong> electrical conductivity are attractive<br />

nanofillers which produce high-performance ceramic composites with multifunctional<br />

properties. The reinforcing effect of CNTs with high aspect ratio is considered<br />

to be analogous to that of continuous or short-fiber-reinforcement. The superior<br />

flexibility of CNTs is very effective in improving the fracture toughness of brittle<br />

ceramics. This is accomplished by means of crack deflection at the CNT–matrix<br />

interface, crack-bridging <strong>and</strong> CNT pull-out mechanisms. Recently, Huang et al.<br />

reported that SWNTs exhibit superplastic deformation with an apparent elongation of<br />

280% at high temperatures [38]. This finding shows the potential application of CNTs<br />

Table 5.1 Mechanical properties of typical micro-nano <strong>and</strong> nano-nano ceramic composites.<br />

Investigators Materials<br />

5.2 Importance of <strong>Ceramic</strong>-Matrix Nanocompositesj135<br />

Bending<br />

strength<br />

(MPa)<br />

Fracture<br />

toughness<br />

(MPa m 1/2 )<br />

Anya Ref [25]<br />

Micro-nano type:<br />

Monolithic Al2O3 (3.5 mm) 430 3.2<br />

Al2O3(4.0 mm)/5 vol% SiC (200 nm) 646 4.6<br />

Al2O3(2.9 mm)/10 vol% SiC (200 nm) 560 5.2<br />

Al2O3(2.6 mm)/15 vol% SiC (200 nm) 549 5.5<br />

Gao et al. Ref [26] Monolithic Al2O3 350 3.5<br />

Al2O3(1.8 mm)/5 vol% SiC (70 nm) 1000 4.0<br />

Zhu et al. Ref [30] Monolithic Al2O3 380 3.9<br />

Al2O3/15vol%Si3N4 (200 nm,<br />

inter; 80 nm, intra)<br />

820 6.0<br />

Isobe et al. Ref [33] Monolithic Al2O3 (1.95 mm) 450 3.7<br />

Al2O3 (0.91 mm)/2.8 vol% Ni<br />

(150 nm, inter; 300 nm, intra)<br />

Nano-nano type:<br />

766 4.6<br />

Bhaduri Ref [34] Al2O3 (44 nm)/10 vol% ZrO2(12.7 nm) — 8.38