Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

46j 2 <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Metal</strong> Nanocomposites<br />

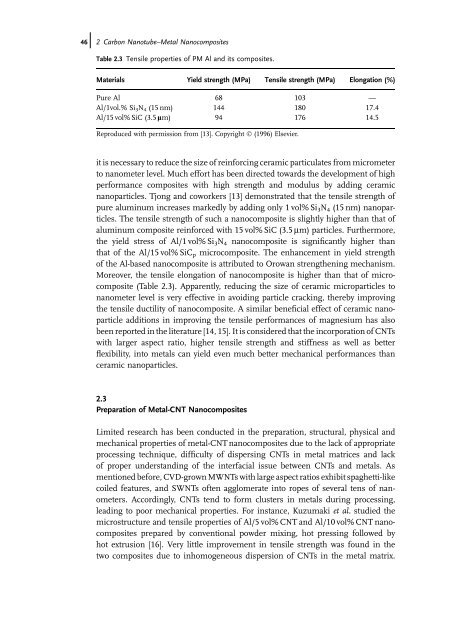

Table 2.3 Tensile properties of PM Al <strong>and</strong> its composites.<br />

Materials Yield strength (MPa) Tensile strength (MPa) Elongation (%)<br />

Pure Al 68 103 —<br />

Al/1vol.% Si3N4 (15 nm) 144 180 17.4<br />

Al/15 vol% SiC (3.5 lm) 94 176 14.5<br />

Reproduced with permission from [13]. Copyright Ó (1996) Elsevier.<br />

it is necessary to reduce the size of reinforcing ceramic particulates from micrometer<br />

to nanometer level. Much effort has been directed towards the development of high<br />

performance composites with high strength <strong>and</strong> modulus by adding ceramic<br />

nanoparticles. Tjong <strong>and</strong> coworkers [13] demonstrated that the tensile strength of<br />

pure aluminum increases markedly by adding only 1 vol% Si3N4 (15 nm) nanoparticles.<br />

The tensile strength of such a nanocomposite is slightly higher than that of<br />

aluminum composite reinforced with 15 vol% SiC (3.5 mm) particles. Furthermore,<br />

the yield stress of Al/1 vol% Si3N4 nanocomposite is significantly higher than<br />

that of the Al/15 vol% SiCp microcomposite. The enhancement in yield strength<br />

of the Al-based nanocomposite is attributed to Orowan strengthening mechanism.<br />

Moreover, the tensile elongation of nanocomposite is higher than that of microcomposite<br />

(Table 2.3). Apparently, reducing the size of ceramic microparticles to<br />

nanometer level is very effective in avoiding particle cracking, thereby improving<br />

the tensile ductility of nanocomposite. A similar beneficial effect of ceramic nanoparticle<br />

additions in improving the tensile performances of magnesium has also<br />

been reported in the literature [14, 15]. It is considered that the incorporation of CNTs<br />

with larger aspect ratio, higher tensile strength <strong>and</strong> stiffness as well as better<br />

flexibility, into metals can yield even much better mechanical performances than<br />

ceramic nanoparticles.<br />

2.3<br />

Preparation of <strong>Metal</strong>-CNT Nanocomposites<br />

Limited research has been conducted in the preparation, structural, physical <strong>and</strong><br />

mechanical properties of metal-CNT nanocomposites due to the lack of appropriate<br />

processing technique, difficulty of dispersing CNTs in metal matrices <strong>and</strong> lack<br />

of proper underst<strong>and</strong>ing of the interfacial issue between CNTs <strong>and</strong> metals. As<br />

mentioned before, CVD-grown MWNTs with large aspect ratios exhibit spaghetti-like<br />

coiled features, <strong>and</strong> SWNTs often agglomerate into ropes of several tens of nanometers.<br />

Accordingly, CNTs tend to form clusters in metals during processing,<br />

leading to poor mechanical properties. For instance, Kuzumaki et al. studied the<br />

microstructure <strong>and</strong> tensile properties of Al/5 vol% CNT <strong>and</strong> Al/10 vol% CNT nanocomposites<br />

prepared by conventional powder mixing, hot pressing followed by<br />

hot extrusion [16]. Very little improvement in tensile strength was found in the<br />

two composites due to inhomogeneous dispersion of CNTs in the metal matrix.