Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

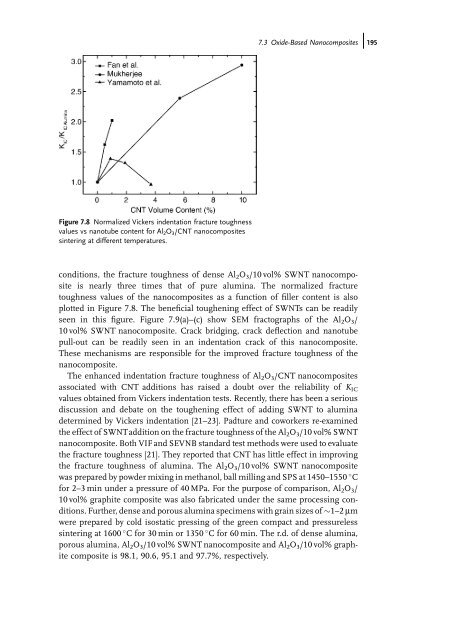

Figure 7.8 Normalized Vickers indentation fracture toughness<br />

values vs nanotube content for Al 2O 3/CNT nanocomposites<br />

sintering at different temperatures.<br />

7.3 Oxide-Based Nanocompositesj195<br />

conditions, the fracture toughness of dense Al2O3/10 vol% SWNT nanocomposite<br />

is nearly three times that of pure alumina. The normalized fracture<br />

toughness values of the nanocomposites as a function of filler content is also<br />

plotted in Figure 7.8. The beneficial toughening effect of SWNTs can be readily<br />

seen in this figure. Figure 7.9(a)–(c) show SEM fractographs of the Al2O3/<br />

10 vol% SWNT nanocomposite. Crack bridging, crack deflection <strong>and</strong> nanotube<br />

pull-out can be readily seen in an indentation crack of this nanocomposite.<br />

These mechanisms are responsible for the improved fracture toughness of the<br />

nanocomposite.<br />

The enhanced indentation fracture toughness of Al 2O 3/CNT nanocomposites<br />

associated with CNT additions has raised a doubt over the reliability of KIC<br />

values obtained from Vickers indentation tests. Recently, there has been a serious<br />

discussion <strong>and</strong> debate on the toughening effect of adding SWNT to alumina<br />

determined by Vickers indentation [21–23]. Padture <strong>and</strong> coworkers re-examined<br />

the effect of SWNTaddition on the fracture toughness of the Al2O3/10 vol% SWNT<br />

nanocomposite. Both VIF <strong>and</strong> SEVNB st<strong>and</strong>ard test methods were used to evaluate<br />

the fracture toughness [21]. They reported that CNT has little effect in improving<br />

the fracture toughness of alumina. The Al 2O 3/10 vol% SWNT nanocomposite<br />

was prepared by powder mixing in methanol, ball milling <strong>and</strong> SPS at 1450–1550 C<br />

for 2–3 min under a pressure of 40 MPa. For the purpose of comparison, Al2O3/<br />

10 vol% graphite composite was also fabricated under the same processing conditions.<br />

Further, dense <strong>and</strong> porous alumina specimens with grain sizes of 1–2 mm<br />

were prepared by cold isostatic pressing of the green compact <strong>and</strong> pressureless<br />

sintering at 1600 C for 30 min or 1350 C for 60 min. The r.d. of dense alumina,<br />

porous alumina, Al2O3/10 vol% SWNT nanocomposite <strong>and</strong> Al2O3/10 vol% graphite<br />

composite is 98.1, 90.6, 95.1 <strong>and</strong> 97.7%, respectively.