Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

96j 3 Physical Properties of <strong>Carbon</strong> <strong>Nanotube</strong>–<strong>Metal</strong> Nanocomposites<br />

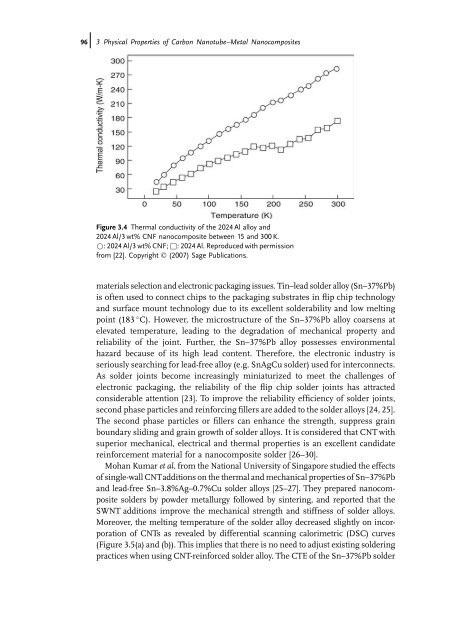

Figure 3.4 Thermal conductivity of the 2024 Al alloy <strong>and</strong><br />

2024 Al/3 wt% CNF nanocomposite between 15 <strong>and</strong> 300 K.<br />

*: 2024 Al/3 wt% CNF; &: 2024 Al. Reproduced with permission<br />

from [22]. Copyright Ó (2007) Sage Publications.<br />

materials selection <strong>and</strong> electronic packaging issues. Tin–lead solder alloy (Sn–37%Pb)<br />

is often used to connect chips to the packaging substrates in flip chip technology<br />

<strong>and</strong> surface mount technology due to its excellent solderability <strong>and</strong> low melting<br />

point (183 C). However, the microstructure of the Sn–37%Pb alloy coarsens at<br />

elevated temperature, leading to the degradation of mechanical property <strong>and</strong><br />

reliability of the joint. Further, the Sn–37%Pb alloy possesses environmental<br />

hazard because of its high lead content. Therefore, the electronic industry is<br />

seriously searching for lead-free alloy (e.g. SnAgCu solder) used for interconnects.<br />

As solder joints become increasingly miniaturized to meet the challenges of<br />

electronic packaging, the reliability of the flip chip solder joints has attracted<br />

considerable attention [23]. To improve the reliability efficiency of solder joints,<br />

second phase particles <strong>and</strong> reinforcing fillers are added to the solder alloys [24, 25].<br />

The second phase particles or fillers can enhance the strength, suppress grain<br />

boundary sliding <strong>and</strong> grain growth of solder alloys. It is considered that CNT with<br />

superior mechanical, electrical <strong>and</strong> thermal properties is an excellent c<strong>and</strong>idate<br />

reinforcement material for a nanocomposite solder [26–30].<br />

Mohan Kumar et al. from the National University of Singapore studied the effects<br />

of single-wall CNTadditions on the thermal <strong>and</strong> mechanical properties of Sn–37%Pb<br />

<strong>and</strong> lead-free Sn–3.8%Ag–0.7%Cu solder alloys [25–27]. They prepared nanocomposite<br />

solders by powder metallurgy followed by sintering, <strong>and</strong> reported that the<br />

SWNT additions improve the mechanical strength <strong>and</strong> stiffness of solder alloys.<br />

Moreover, the melting temperature of the solder alloy decreased slightly on incorporation<br />

of CNTs as revealed by differential scanning calorimetric (DSC) curves<br />

(Figure 3.5(a) <strong>and</strong> (b)). This implies that there is no need to adjust existing soldering<br />

practices when using CNT-reinforced solder alloy. The CTE of the Sn–37%Pb solder