Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Carbon Nanotube Reinforced Composites: Metal and Ceramic ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

sintered at 1500 C are responsible for its poorest fracture toughness <strong>and</strong> lowest<br />

bending stress. Reducing the sinter temperature to 1450 C leads to a marked<br />

increase of the bending stress (554 MPa) <strong>and</strong> VIF toughness (3.9 MPa m 1/2 ).<br />

The fracture toughness of nanocomposite increases with decreasing sinter temperature.<br />

Comparing the fracture toughness values of monolithic alumina sintered at<br />

the same temperature, it appears that the toughening efficiency of MWNT in alumina<br />

is very low. The fracture toughness of nanocomposite hot pressed at 1500 Cis<br />

even smaller than that of alumina sintered at 1500 C. There is no improvement in<br />

fracture toughness of the nanocomposite hot pressed at 1450 <strong>and</strong> 1400 C. The<br />

fracture toughness of nanocomposite hot pressed at 1350 C improves by nearly<br />

33.3% compared with the single-phase alumina sintered at 1350 C. The poor<br />

toughness of the nanocomposite hot pressed at 1400–1500 C is attributed to the<br />

degradation of CNTs [Chap. 5, Ref. 53, Chap. 5, Ref. 69]. It is quite obvious that<br />

the hot-pressing temperature must be reduced to lower temperatures to preserve<br />

the structure of CNTs.<br />

In another study, Sun et al. employed SPS to consolidate the Al2O3/0.1 wt% CNT<br />

nanocomposite <strong>and</strong> single-phase alumina at 1300 C for 5 min [Chap. 5, Ref. 61].<br />

Obviously, the addition of only 0.1 wt% CNT to alumina increases the fracture<br />

toughness by about 32.4% from 3.7 to 4.9 MPa m 1/2 . Compared with hot pressing,<br />

only one-tenth of CNT content is needed to improve the toughness of alumina<br />

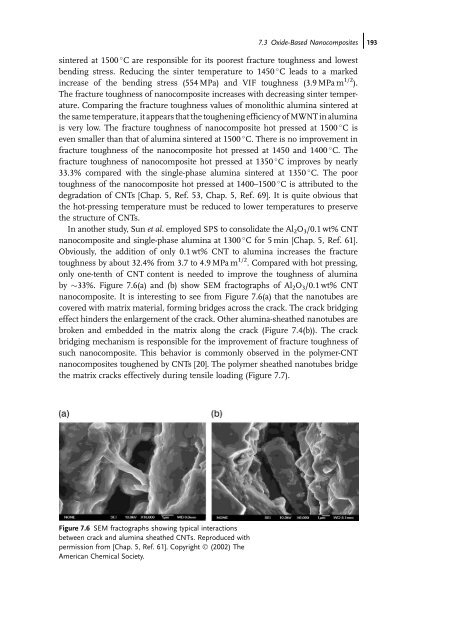

by 33%. Figure 7.6(a) <strong>and</strong> (b) show SEM fractographs of Al2O3/0.1 wt% CNT<br />

nanocomposite. It is interesting to see from Figure 7.6(a) that the nanotubes are<br />

covered with matrix material, forming bridges across the crack. The crack bridging<br />

effect hinders the enlargement of the crack. Other alumina-sheathed nanotubes are<br />

broken <strong>and</strong> embedded in the matrix along the crack (Figure 7.4(b)). The crack<br />

bridging mechanism is responsible for the improvement of fracture toughness of<br />

such nanocomposite. This behavior is commonly observed in the polymer-CNT<br />

nanocomposites toughened by CNTs [20]. The polymer sheathed nanotubes bridge<br />

the matrix cracks effectively during tensile loading (Figure 7.7).<br />

Figure 7.6 SEM fractographs showing typical interactions<br />

between crack <strong>and</strong> alumina sheathed CNTs. Reproduced with<br />

permission from [Chap. 5, Ref. 61]. Copyright Ó (2002) The<br />

American Chemical Society.<br />

7.3 Oxide-Based Nanocompositesj193