- Page 1 and 2: Report SeriesTomeArchitectureand ma

- Page 3 and 4: C.RP.ADP.04.00013/495ContentsConten

- Page 5 and 6: C.RP.ADP.04.00015/4955.3.2 Design p

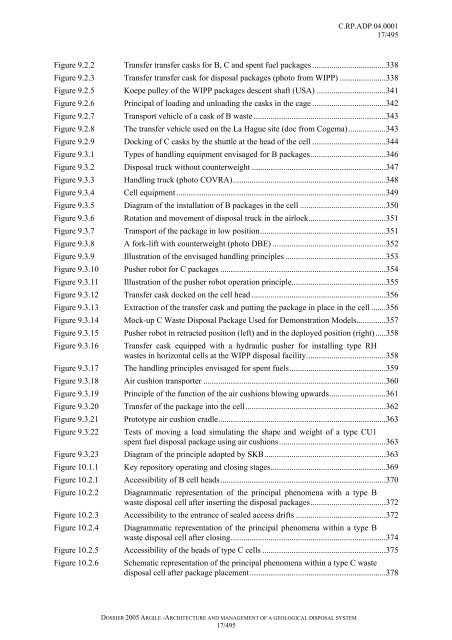

- Page 7 and 8: C.RP.ADP.04.00017/4959.2.3 The tran

- Page 9 and 10: C.RP.ADP.04.00019/495Bibliographic

- Page 11 and 12: C.RP.ADP.04.000111/495Table of illu

- Page 13 and 14: C.RP.ADP.04.000113/495Figure 4.3.8

- Page 15: C.RP.ADP.04.000115/495Figure 5.3.9F

- Page 19 and 20: C.RP.ADP.04.000119/495Figure 10.4.8

- Page 21: C.RP.ADP.04.000121/495Table 11.6.1T

- Page 24 and 25: 1 - The Study Approach1.1 Purpose o

- Page 26 and 27: 1 - The Study ApproachFrom 1999 to

- Page 28 and 29: 1 - The Study Approach1.4 Structure

- Page 30 and 31: 2 - General DescriptionThis chapter

- Page 32 and 33: 2 - General DescriptionHLLL waste p

- Page 34 and 35: 2 - General DescriptionFor a transi

- Page 36 and 37: 2 - General DescriptionIt should al

- Page 38 and 39: 2 - General Description2.2.2.2 Safe

- Page 40 and 41: 2 - General DescriptionThe protecti

- Page 42 and 43: 2 - General DescriptionIt should al

- Page 44 and 45: 2 - General DescriptionThis section

- Page 46 and 47: 2 - General Descriptionfollowing th

- Page 48 and 49: 2 - General Description2.3.2.2 Geoc

- Page 50 and 51: 2 - General DescriptionFigure 2.3.5

- Page 52 and 53: 2 - General DescriptionIn the Dogge

- Page 54 and 55: 2 - General DescriptionFigure 2.4.1

- Page 56 and 57: 2 - General Description• A dimens

- Page 58 and 59: 2 - General Description2.4.1.2 Desi

- Page 60 and 61: 2 - General DescriptionFigure 2.4.4

- Page 62 and 63: 2 - General DescriptionFigure 2.4.6

- Page 64 and 65: 2 - General DescriptionFigure 2.4.8

- Page 66 and 67:

2 - General Description- some conne

- Page 68 and 69:

2 - General DescriptionAs for the w

- Page 70 and 71:

2 - General DescriptionThe figure b

- Page 73 and 74:

33High-level long-lived waste3.1 Wa

- Page 75 and 76:

3 - High Level Long-Lived WasteRese

- Page 77 and 78:

3 - High Level Long-Lived Wastesupp

- Page 79 and 80:

3 - High Level Long-Lived WasteThe

- Page 81 and 82:

3 - High Level Long-Lived WasteFigu

- Page 83 and 84:

3 - High Level Long-Lived WasteA fi

- Page 85 and 86:

3 - High Level Long-Lived WasteThe

- Page 87 and 88:

3 - High Level Long-Lived WasteFigu

- Page 89 and 90:

3 - High Level Long-Lived WasteA se

- Page 91 and 92:

3 - High Level Long-Lived WasteVitr

- Page 93 and 94:

3 - High Level Long-Lived WasteFigu

- Page 95 and 96:

3 - High Level Long-Lived WasteCond

- Page 97 and 98:

3 - High Level Long-Lived WasteThe

- Page 99 and 100:

3 - High Level Long-Lived WasteDist

- Page 101 and 102:

3 - High Level Long-Lived Waste3.3.

- Page 103 and 104:

3 - High Level Long-Lived WasteTabl

- Page 105 and 106:

44Waste disposal packages4.1 B disp

- Page 107 and 108:

4 - Waste disposal PackagesFor empl

- Page 109 and 110:

4 - Waste disposal Packages• Safe

- Page 111 and 112:

4 - Waste disposal Packages• "Par

- Page 113 and 114:

4 - Waste disposal PackagesThe prin

- Page 115 and 116:

4 - Waste disposal PackagesThe seco

- Page 117 and 118:

4 - Waste disposal PackagesFigure 4

- Page 119 and 120:

4 - Waste disposal PackagesFigure 4

- Page 121:

4 - Waste disposal Packages4.1.5 Th

- Page 124 and 125:

4 - Waste disposal Packages4.1.5.7

- Page 126 and 127:

4 - Waste disposal PackagesFigure 4

- Page 128 and 129:

4 - Waste disposal PackagesIn the c

- Page 130 and 131:

4 - Waste disposal PackagesFinally,

- Page 132 and 133:

4 - Waste disposal PackagesThe YAG

- Page 134 and 135:

4 - Waste disposal PackagesIn the U

- Page 136 and 137:

4 - Waste disposal Packages4.2.3.2

- Page 138 and 139:

4 - Waste disposal PackagesThe spee

- Page 140 and 141:

4 - Waste disposal Packages4.2.4 Ma

- Page 142 and 143:

4 - Waste disposal PackagesLoadSlid

- Page 144 and 145:

4 - Waste disposal Packages4.3 Spen

- Page 146 and 147:

4 - Waste disposal PackagesThe seco

- Page 148 and 149:

4 - Waste disposal Packages4.3.3.1

- Page 150 and 151:

4 - Waste disposal PackagesFor both

- Page 152 and 153:

4 - Waste disposal Packages• Safe

- Page 154 and 155:

4 - Waste disposal PackagesAs for C

- Page 156 and 157:

4 - Waste disposal PackagesMelted c

- Page 159 and 160:

55Repository modules.5.1 B waste re

- Page 161 and 162:

5 - Repository Modules5.1.1.1 Quest

- Page 163 and 164:

5 - Repository Modules• Controlli

- Page 165 and 166:

5 - Repository ModulesFigure 5.1.1t

- Page 167 and 168:

5 - Repository Modules• The geome

- Page 169 and 170:

5 - Repository ModulesTable 5.1.1Fu

- Page 171 and 172:

5 - Repository ModulesFigure 5.1.9D

- Page 173 and 174:

5 - Repository Modules5.1.3.2 Detai

- Page 175 and 176:

5 - Repository Modules• Arrangeme

- Page 177 and 178:

5 - Repository ModulesAlthough this

- Page 179 and 180:

5 - Repository ModulesConnection be

- Page 181 and 182:

5 - Repository ModulesFurthermore,

- Page 183 and 184:

5 - Repository ModulesTo illustrate

- Page 185 and 186:

5 - Repository Modules• The acces

- Page 187 and 188:

5 - Repository ModulesFigure 5.1.24

- Page 189 and 190:

5 - Repository ModulesFigure 5.1.26

- Page 191 and 192:

5 - Repository Modules• Limiting

- Page 193 and 194:

5 - Repository Modules5.2.2 Design

- Page 195 and 196:

5 - Repository ModulesA concept wit

- Page 197 and 198:

5 - Repository Modules• Orientati

- Page 199 and 200:

5 - Repository ModulesFigure 5.2.3O

- Page 201 and 202:

5 - Repository Modules5.2.3.1 Descr

- Page 203 and 204:

5 - Repository ModulesA minimum ann

- Page 205 and 206:

5 - Repository ModulesIn terms of t

- Page 207 and 208:

5 - Repository ModulesStorage perio

- Page 209 and 210:

5 - Repository ModulesFigure 5.2.13

- Page 211 and 212:

5 - Repository ModulesSensitivity t

- Page 213 and 214:

5 - Repository ModulesIt must be no

- Page 215 and 216:

5 - Repository Modules• Disposal

- Page 217 and 218:

5 - Repository ModulesFigure 5.2.18

- Page 219 and 220:

5 - Repository Modules• Assembly

- Page 221 and 222:

5 - Repository ModulesFigure 5.2.21

- Page 223 and 224:

5 - Repository ModulesThe permeabil

- Page 225 and 226:

5 - Repository ModulesThe evolution

- Page 227 and 228:

5 - Repository ModulesThe lowest dr

- Page 229 and 230:

5 - Repository Modules• Back-fill

- Page 231 and 232:

5 - Repository Modules5.3.2.1 Sever

- Page 233 and 234:

5 - Repository ModulesFigure 5.3.4S

- Page 235 and 236:

5 - Repository ModulesThe cells are

- Page 237 and 238:

5 - Repository ModulesFigure 5.3.8

- Page 239 and 240:

5 - Repository ModulesFinally, it s

- Page 241 and 242:

5 - Repository ModulesThe internal

- Page 243 and 244:

5 - Repository Modules• Descripti

- Page 245 and 246:

5 - Repository ModulesFigure 5.3.14

- Page 247 and 248:

5 - Repository ModulesFigure 5.3.17

- Page 249 and 250:

5 - Repository Modules- another pos

- Page 251 and 252:

66 Overall undergroundarchitecture6

- Page 253 and 254:

6 - Overall underground architectur

- Page 255 and 256:

6 - Overall underground architectur

- Page 257 and 258:

6 - Overall underground architectur

- Page 259 and 260:

6 - Overall underground architectur

- Page 261 and 262:

6 - Overall underground architectur

- Page 263 and 264:

6 - Overall underground architectur

- Page 265 and 266:

6 - Overall underground architectur

- Page 267 and 268:

6 - Overall underground architectur

- Page 269 and 270:

6 - Overall underground architectur

- Page 271 and 272:

6 - Overall underground architectur

- Page 273 and 274:

6 - Overall underground architectur

- Page 275 and 276:

6 - Overall underground architectur

- Page 277 and 278:

6 - Overall underground architectur

- Page 279 and 280:

6 - Overall underground architectur

- Page 281 and 282:

6 - Overall underground architectur

- Page 283 and 284:

6 - Overall underground architectur

- Page 285 and 286:

6 - Overall underground architectur

- Page 287:

6 - Overall underground architectur

- Page 290 and 291:

7 - The shafts and the driftsThe co

- Page 292 and 293:

7 - The shafts and the drifts7.2.2

- Page 294 and 295:

7 - The shafts and the driftsFigure

- Page 296 and 297:

7 - The shafts and the drifts7.3.3.

- Page 298 and 299:

7 - The shafts and the drifts7.3.4.

- Page 300 and 301:

7 - The shafts and the drifts7.4 De

- Page 302 and 303:

7 - The shafts and the driftsFigure

- Page 304 and 305:

7 - The shafts and the driftsThe dr

- Page 306 and 307:

7 - The shafts and the driftsFigure

- Page 308 and 309:

7 - The shafts and the drifts7.7 Cl

- Page 310 and 311:

7 - The shafts and the drifts7.7.2.

- Page 312 and 313:

7 - The shafts and the driftspressu

- Page 314 and 315:

7 - The shafts and the drifts7.7.2.

- Page 316 and 317:

7 - The shafts and the driftsFigure

- Page 318 and 319:

7 - The shafts and the drifts7.7.3.

- Page 321 and 322:

88Surface installations8.1 General

- Page 323 and 324:

8 - Surface installationsFigure 8.1

- Page 325 and 326:

8 - Surface installationsSuch a bui

- Page 327:

8 - Surface installationsApart from

- Page 330 and 331:

9 - Nuclear operating resources in

- Page 332 and 333:

9 - Nuclear operating resources in

- Page 334 and 335:

9 - Nuclear operating resources in

- Page 336 and 337:

9 - Nuclear operating resources in

- Page 338 and 339:

9 - Nuclear operating resources in

- Page 340 and 341:

9 - Nuclear operating resources in

- Page 342 and 343:

9 - Nuclear operating resources in

- Page 344 and 345:

9 - Nuclear operating resources in

- Page 346 and 347:

9 - Nuclear operating resources in

- Page 348 and 349:

9 - Nuclear operating resources in

- Page 350 and 351:

9 - Nuclear operating resources in

- Page 352 and 353:

9 - Nuclear operating resources in

- Page 354 and 355:

9 - Nuclear operating resources in

- Page 356 and 357:

9 - Nuclear operating resources in

- Page 358 and 359:

9 - Nuclear operating resources in

- Page 360 and 361:

9 - Nuclear operating resources in

- Page 362 and 363:

9 - Nuclear operating resources in

- Page 365 and 366:

1010 Reversible repositorymanagemen

- Page 367 and 368:

During the operational phase, the d

- Page 369 and 370:

Figure 10.1.1Key repository operati

- Page 371 and 372:

The radioactive elements can thus b

- Page 373 and 374:

Furthermore, equipment and liner ma

- Page 375 and 376:

The condition of the access drifts

- Page 377 and 378:

The sleeve’s durability is improv

- Page 379 and 380:

10.2.2.2 “Post cell-sealing” st

- Page 381 and 382:

As far as long-term safety is conce

- Page 383 and 384:

Figure 10.2.10Diagrammatic represen

- Page 385 and 386:

10.3.1.1 Overview of the principal

- Page 387 and 388:

10.3.2.2 Monitoring of type C waste

- Page 389 and 390:

The project’s monitoring programm

- Page 391 and 392:

• Absence of a significant impact

- Page 393 and 394:

Dams are of particular interest whe

- Page 395 and 396:

The rate of operation of these sens

- Page 397 and 398:

• Water contentThe water content

- Page 399 and 400:

A similar wireless transmission tec

- Page 401 and 402:

Figure 10.3.9Example of monitoring

- Page 403 and 404:

In addition, a visual control syste

- Page 405 and 406:

Cell atmosphere monitoring is limit

- Page 407 and 408:

The monitoring of the seal can be c

- Page 409 and 410:

• The instrumented sections and t

- Page 411 and 412:

The deformation measurements carrie

- Page 413 and 414:

10.3.9 Observation of spent fuel di

- Page 415 and 416:

These instrumented sections (cf. §

- Page 417 and 418:

The monitoring equipment embedded i

- Page 419 and 420:

the cell which conditions the evolu

- Page 421 and 422:

Figure 10.4.2Cell filled with B pac

- Page 423 and 424:

Ventilation of a 250-m long cell re

- Page 425 and 426:

• Package retrieval processOnce t

- Page 427 and 428:

Figure 10.4.10C Cell at end of oper

- Page 429 and 430:

The robot is traversed similarly to

- Page 431 and 432:

This operation is complete when a b

- Page 433 and 434:

The condition of the drift liner sh

- Page 435 and 436:

1111 Operational Safety11.1 Evaluat

- Page 437 and 438:

11 - Operational SafetyTransport tr

- Page 439 and 440:

11 - Operational SafetyTable 11.1.1

- Page 441 and 442:

11 - Operational SafetyResultsTable

- Page 443 and 444:

11 - Operational SafetyThe risks ar

- Page 445 and 446:

11 - Operational SafetyTable 11.2.1

- Page 447 and 448:

11 - Operational SafetyOn the surfa

- Page 449 and 450:

11 - Operational Safety“Honeycomb

- Page 451 and 452:

11 - Operational SafetyGiven the me

- Page 453 and 454:

11 - Operational SafetyThis risk co

- Page 455 and 456:

11 - Operational SafetyHydrogen emi

- Page 457 and 458:

11 - Operational SafetyOver and abo

- Page 459 and 460:

11 - Operational SafetyFigure 11.4.

- Page 461 and 462:

11 - Operational SafetyFigure 11.4.

- Page 463 and 464:

11 - Operational SafetyHowever, wit

- Page 465 and 466:

11 - Operational SafetyTable 11.5.1

- Page 467 and 468:

11 - Operational SafetyFigure 11.5.

- Page 469 and 470:

11 - Operational Safety11.5.2 Concl

- Page 471 and 472:

11 - Operational SafetyFigure 11.6.

- Page 473 and 474:

11 - Operational Safety11.7.1 Asses

- Page 475 and 476:

11 - Operational SafetyTable 11.7.2

- Page 477 and 478:

11 - Operational SafetySuch a damag

- Page 479 and 480:

11 - Operational Safety11.8.1.2 Dat

- Page 481 and 482:

11 - Operational SafetyIn all cases

- Page 483 and 484:

1212 Synthesis12.1 Simple and robus

- Page 485 and 486:

12 - SynthesisThe existence of unce

- Page 487:

12 - SynthesisTo concretely illustr

- Page 490 and 491:

Bibliographic references[17] Callon

- Page 492 and 493:

Bibliographic references[54] Andra

- Page 494 and 495:

Bibliographic references[88] IAEA (

- Page 496 and 497:

Photo Credits:ANDRA - AREVA CREATIV