work plan for soil remediation, sampling and analysis plan, site ...

work plan for soil remediation, sampling and analysis plan, site ...

work plan for soil remediation, sampling and analysis plan, site ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

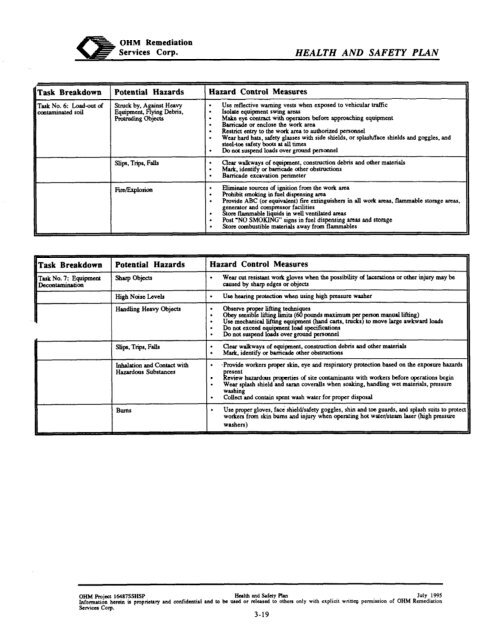

((Task Breakdown 1 Potential Hazards Hazard Control MeasuresTaaraa&L$~ut of Struck by. Against HeavyEquipment, Flying Debris,Protruding Objects. Use reflective warning vests when exposed to vehicular traftic. Isolate equipment swing areas. Make eye contract with operators be<strong>for</strong>e approaching equipment. Barricade or enclose the <strong>work</strong> area. Restrict entry to the <strong>work</strong> area to authorized personnel. Wear hard hats, safety glasses with side shields, or splash/face shields <strong>and</strong> goggles, <strong>and</strong>stecLtoe safety boots at all times. Do not suspend loads over ground personnelSlips, Trips,Fire/JzxplosionFalls. Clear walkways of equipment, constmction debris <strong>and</strong> other materials. Mark, identify or barricade other obstructions. Barricade excavation Perimeter. Eliminate sources of ignition fmm the <strong>work</strong> area. Prohibit smoking in fuel dispensing area. Provide ABC (or equivalent) fire extinguishers in all <strong>work</strong> amas, flammable storage areas,generator <strong>and</strong> compmssor facilities. Store flammable liquids in well ventilated areas. Post ‘NO SMOKING” signs in fuel dispensing areas <strong>and</strong> storage. Store combustible materials away from flammablesTask Breakdown Potential Hazards Hazard Control MeasuresTask No. 7: Equipment Sharp Objects . Wear cut resistant <strong>work</strong> gloves when the possibility of lacerations or other injury may beDeconrallliMtion caused by sharp edges or objectsHiab Noise L-evels I- Use hearing protection when using high pressure washerSlips, Trips, Falls..Observe prorr lifting +hn$esObey sennb e hftmg bmtts ( pouuds maximum per. Use mechanical lifting quipment (h<strong>and</strong> carts, trucks f”. Do nat exceed qui ent load specifications. Do not susnend 1 oar s over around nerscnnel. Clear walkways of equipmmt. construction debris <strong>and</strong> other materials. Mark, identify or barricade other obstructionsrson manual liing)to move large awkward loadsInhalation <strong>and</strong> Contact withHazardous SubstancesrBums.. .Pmvide <strong>work</strong>ers proper skin. eye <strong>and</strong> respiratory protection based on the exposure hazards. ii%% hazudous p+ r-ties of <strong>site</strong> contaminants with <strong>work</strong>ers be<strong>for</strong>e operations begin. Wear splash shield an Satan coveralls when soaking, h<strong>and</strong>ling wet materials, pressurewashing. Collect <strong>and</strong> contain spent wash water <strong>for</strong> pmper disposalUse pmper gloves, face shield/safety goggles, shin <strong>and</strong> toe guards. <strong>and</strong> splash suits to pmted<strong>work</strong>ers frun skin bums <strong>and</strong> injury when operating hot water/steam laser (high pressurewashers)OHM Project 16487SSHSP Health <strong>and</strong> Safer, Plan July 1995In<strong>for</strong>mation herein is proprietary <strong>and</strong> confidential <strong>and</strong> to be used or t~lcpscd to others only with explicit writr~~ permission of OHM RancdiationSctvicca Corp.3-19