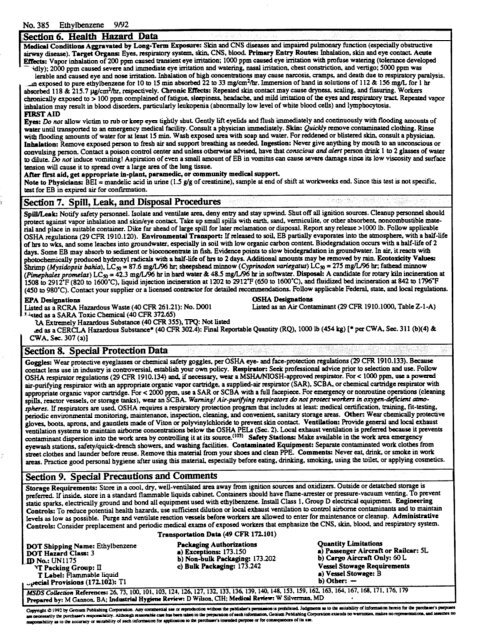

apSix.lion 1. Material Identification:Genium Publishing Corporation Material Safety Data Sheets Collection:Sheet No. 385Schenectady,USA Ethylbenzeneone Genium PIazaNY 12304490(518) 377-8854Issued: 8/78 Revision: B, 9192Ethylbenzene (CJi&Hs) Description: Derived by heating benzene <strong>and</strong> ethylene in presence of aluminum chloride with R 1 NFPAsubsequent distillation, by fractionation directly from the mixed xylene stream in petroleum reftig, or Qhydrogetmtion I 3of naphthenes. Used as a solvent. an antiknock agent in gasoline: <strong>and</strong> as an intermediateproduction of synthetic rubber, S 2*230stymne. cellulose acetate, diethylbenxen~ acetophenone, ethyl anthraquinone. propyl oxide, <strong>and</strong> a-methylbenxol alcohol. FSb4 _Other Deaignationse CAS No. 100414. ethylbenxnl, EB. phenylethane. NCIC56393.49Manufacturec Contact your supplier or distributor. Consult latest Chemical Week Buyers' Guidcm) <strong>for</strong> a suppha~ list, absolptioa I+fIsCautions: Ethylbenzene is a skin <strong>and</strong> mucous membrane irritant considered the most irritating of the benxene series. Inhalationcauses acute <strong>and</strong> chronic central nervou system (CNS) effects. It is highly flammable <strong>and</strong> <strong>for</strong>ms explosive m&nrea with air.: Section 2. Ingredients <strong>and</strong> Occupational Exposure LimitsEthylbenzene, ca >99.0%. Impurities include - 0.1% meta & puru xylene. - 0.1% cumene, <strong>and</strong> - 0.1% toluene.39F PR 0PPE-See8t cbroaiceffeas1991 OSHA PELa 1992.93 ACGIH TLVs 1985-86 Toxicity Data*8-hr TWA: 100 ppm (435 mg/m3) TWA: 100 ppm (434 mg/m’) Human. inhalation. TClp: 100 ppmEs hr caused eye effects.15-min STEL: 125 ppm (545 mg/m’) STEL: 125 ppm (545 mg/m3) sleep, <strong>and</strong> respiratory changes.Action Level: 50 ppm (217 mg/m3) 1990 DPG (Germany) MAK Human, lymphocyte: 1 mmol/L induced sister chtomatid1990 IDLH Level TWA: 100 ppm (440 mg/m3) exchange.2000 mm catcgoly 1: local i&ants Rat. OraL LD,: 3500 mgAtg; toxic effects not yet reviewed1990 NIOSH RRLPeak Exposure Limit 200 ppm. 5 min Rat (female). itlhalati0~ T&: 1000 ppml7 hr/day, 5 days/momentary value, max of S/shiftTWA: 100 ppm (435 mg/m’)wk. <strong>for</strong> 3 wk prior to mating <strong>and</strong> daily <strong>for</strong> 19 days of gesta-Danger of cutaneous absorptionSTEL: 125 ppm (545 mg/m3)tion produced pups with high lncldence of exna ribs!*rs)l See NIOSH, RTECS @Ao700000), fcr additioaal initatioa, mutatioa, reproductive, aad toxicity date.:&-on 3, physic& Data, i.i:-:.:-i,,.i.i.:;:;::-: ..i~::,~::,,:~:i:“i.:.-::..: ..: . ::.;.:‘1: ::.;;i :I’..-.i;j,,,f.,:. :,:,;,~.;:i.~;;;:.:f :::j:~;:.~Rolling Point: 277 ‘F (136‘C) Mokedar Weight: 106.16Melting Point: -139‘F (-95‘C) Density 0.863 at 77 ‘F (25 ‘C)Surface Tension: 31 J dyndcm Watar Solubility: Slightly. 14 mg/lOO mL at 59 ‘F (15‘C)IonizationViscosity:Potent&l: 8.76 eV0.64 CP at 77 ‘F (25‘C) Other Solubilities: Miscible in alcohol, etha, soluble in carbon tetrachloride. benzene.suIfur dioxide, <strong>and</strong> many organic solvents. insoluble in ammoniaR&action Index: 1.4959 at 68 ‘F (20‘C)Odor ThreshokI: 2.3 ppmRelative Evaporation Rate (ether = 1): 0.0106Bulk Density: 7.21 lb/Gal at 77 ‘F (25‘C) Vapor Pressure: 7.1 nun Hg at 68 ‘F (20‘C); 10 mmHg at 78.62 ‘F (25.9‘C); 100 mm Hg165.38 ‘F (74.1‘C)~ Critics1 Temperature: 65 1 ‘F (343.9 l C) Saturated Vapor Density (Air = 0.075 lb/p or 1.2 kg/m’> 0.0768 lb/n’, or 1.2298 kg/m31 Critical Pressure: 35.6 atmAppearance <strong>and</strong> Odor: Colorless, flammable liquid with a pungent odor.Section 4. Fire <strong>and</strong> Explosion Data ... :Ii&tab Point: 64 ‘F (18 ‘C) CC 1 Autoignition Temperature: 810 l F (432‘C) 1 LEL: 1.0% v/v 1 LJEL: 6.7% v/vExtinguishing Media: Class 1 B Flammable liquid. For small fires. use dry chemical, carbon dioxide, or ‘alcohol-msistant’ foam. For large fues, us(fog or ‘alcohol-resistant’ foam. Use water only if other agents are unavailable: EB floats on water <strong>and</strong> may travel to an ignition source <strong>and</strong> spreadfire. Unusual Fire or Explosion Haxardat Burning rate = 5.8 mm/mm. Vapors may travel to an ignition source <strong>and</strong> flash back. Container mayexplode in heat of fire. EB poses a vapor explosion hazard indoors, outdoors, <strong>and</strong> in sewas. Special Fin-fighting Procedures: Because fire mayproduce toxic thermal decomposition products, wear a self-contained breathing apparatus (SCBA) with a full facepiece operated in pressure-dem<strong>and</strong>or positive-pressure mode. Cool container sides with water until well after fue is out Stay away from ends of tanks. For massive fire in cargo area,usa monitor nozles or unmanned hose holders; if impossible, withdraw from area <strong>and</strong> let fue burn. Withdraw immediately if you hear rising soundfrom venting safety device or notice any tank diiloration due to fire. Do not release runoff from fire contml methods to sewers or waterways.Section 5. Reactivity DataS~bfi~/Polymer~tion: E~ylbemene is stable at room temperature in closed containers under normal storage <strong>and</strong> h<strong>and</strong>ling conditions. Hazardoupolymerization cannot occur.Chemicai Incompatibilitk Reacts vigorously with oxidiizer~.Conditions to Avoid: Exposure to heat <strong>and</strong> oxidizer.I&xardoua Product.9 uf Decomposit~n: Thermal oxidative decomposition of EB can produce acrid smoke <strong>and</strong> irritating fumes.Section 6. Health Hazard DataCarcinogenicity: The IARC. (I&) NTP.(169) <strong>and</strong> OSHA(t*l do not list EB as a carcinogen. Summary of Risk Occupational exposure to EB aloneis rare since it is usually presentogether with other solvents. EB is irritating to the eyes. skin, <strong>and</strong> respiratory tract. Vapor inhalation ptoducesvarying degrees of CNS effects depending on concentration. The liquid is absorbed thtough the skin but vapon are not. 56 to 64% of inhaledethylbenzene is retained <strong>and</strong> metabolized. Urinary mefabolites following exposure to 23 to 85 ppm <strong>for</strong> 8 hr are m<strong>and</strong>eiic acid (64%). phenylglyoxylicacid (25%). <strong>and</strong> methylphenylcarbinoYl-phenyl ethanol (5%). Concurrent exposure to xylene <strong>and</strong> ethylbenzene causeslower excretionof EB metabolites. Based on the rat II&, one manufacturer gives 3 to 4 oz. as the lethal dose <strong>for</strong> a 100 lb person. CmliNit on next plgcCopyhgbt a 1992 Gmum Publisinnfi Cuponum. My cummtxd am Q fqmthaim VilboM the pblihefr prmurim is pobibiti

\;Section 6. Health HazardDataMe&d Conditions Aggravated by Long-Term Exposure: Skin <strong>and</strong> CNS diseases <strong>and</strong> impaired pulmonary function (especially obstructiveairway disease). Target Organs Eyes. respiratory system. skin, CNS, blood. Primary Entry Routa: hhalati~n. skin <strong>and</strong> eye contact AcuteEfktsz Vapor inhalation of 200 ppm caused ttansient eye initati~n; 1000 ppm caused eye irritation with profuse watering (tolersnce developed- ‘idly); 2000 ppm caused severe <strong>and</strong> immediateye irritation <strong>and</strong> watering, nasal irritation, chest constriction, <strong>and</strong> vertigo; 5000 ppm waslerable <strong>and</strong> caused eye <strong>and</strong> nose irritation. Inhalation of high concentrations may cause narcosis, cramps, <strong>and</strong> death due to respiratory paralysis.-ur exposed to pure ethylbenzene <strong>for</strong> 10 to 15 mm absorbed 22 to 33 mg/cm%r. Immersion of h<strong>and</strong> in solutions of 112 & 156 mg/L <strong>for</strong> 1 hrabsorbed 118 & 215.7 pg/cm%r, respectively. Cbmnic EKectst Repeated skin contact may cause dryness, scaling, <strong>and</strong> fmuring. Workerschmnically exposed to > 100 ppm complained of fatigue, sleepiness. headache. <strong>and</strong> mild irritation of the eyes <strong>and</strong> respiratory tract Repeated vapork&huion may result in blood disorders, particularly leukopenia (abnormally low level of white blood cells) <strong>and</strong> lymphocytosis.FIRST AIDEyer: Do nor allow victim to rub or keep eyes tightly shut. Gently lift eyelids <strong>and</strong> flush immediately <strong>and</strong> continuously with flooding amounts ofwater until transported to an emergency medical facility. Consult a physician immediately. Skin: Quickly remove contaminated clothing. Rinsewith floodiig amounts of water <strong>for</strong> at least 15 min. Wash exposed area with soap <strong>and</strong> water. For reddened or blistered skin, consult a physician.Inhalation: Remove exposed person to fresh air <strong>and</strong> support breathing as needed. Ingestion: Never give anything by mouth to an unconscious orconvulsing person. Contact a poison control center <strong>and</strong> unless otherwise advised, have that conscious <strong>and</strong> uZ.err person drink 1 to 2 glasses of waterto dilute. Do nor induce vomiting! Aspiration of even a small amount of EB in vomitus can cause severe damage since its low viscosity <strong>and</strong> surfacetension will cause it to spread over a large area of the lung tissue.After Btut aid, get appropriate in-<strong>plan</strong>t, peramedic, or community medical support.Note to Physicians: BEI = m<strong>and</strong>elic acid in urine (1.5 g/g of creatinine). sample at end of shift at worhveeks end. Since this test is not specific,test <strong>for</strong> EB in exoired air <strong>for</strong> confutation.Section 7. Spill, Leak, <strong>and</strong> Disposal Procedures ’Spill/Leak: Notify safety personnel. Isolate <strong>and</strong> ventilate are& deny entry <strong>and</strong> stay upwind Shut off all ignition sources. Cleanu personnel shouldprotect against vapor inhalation <strong>and</strong> skin/eye contact Take up small spills with earth. s<strong>and</strong>. vermiculite. or other absorbent, noncombustible material<strong>and</strong> place in suitable container. Dike far ahead of large spill <strong>for</strong> later reclamation or disposal. Report any release >lOOO lb. Follow applicableOSHA regulations (29 CFR 1910.120). Environmental Transport: If released to <strong>soil</strong>, EB partially evaporates into the atmosphere, with a half-lifeof hrs to wks, <strong>and</strong> some leaches into groundwater. especially in <strong>soil</strong> with low organic carbon content Biodegradation occurs with a half-life of 2days. Some EB may absorb to sediment or bioconcenttate in f& Evidence points to slow biodegradation in groundwater. In air, it reacts withphotochemically produced hydroxyl radicals with a half-life of hrs to 2 days. Additional amounts may be removed by rain. Ecotoxicity ValuesShrimp (hfysidupsis buhiu). LCa = 87.6 mgN% hr; sheepshead minnow (Cyprinodon varieg~ur) LCm = 275 mg/U% hr; fathead minnow(Pimephufes prmtuZus) LCm = 42.3 mg/U% hr in bard water & 48.5 mgN% hr in &water. Disposal: A c<strong>and</strong>idate <strong>for</strong> rotary kiln incineration at1508 to 2912’F (820 to 16OO’C). liquid injection incineration at 1202 to 2912’F (650 to 16OO’C). <strong>and</strong> fluidi& bed incineration at 842 to 17%‘F(450 to 98O’C). Contact your supplier or a licensed contractor <strong>for</strong> detailed recommendations. Follow applicable Federal, state, <strong>and</strong> local regulations.EPA DesignationsOSHA DesignationsListed as a RCRA Hazardous Waste (40 CFR 261.21): No. DO01 Listed as an Air Contaminant (29 CFR 1910.1000, Table Z-l-A)3.bted as a SARA Toxic Chemical (40 CFR 37265)IA Extremely Haxardous Substance (40 CFR 355). TPQ: Not listed&as aCERCLA Haxatdous Substance* (40 CFR 302.4): Fmal Reportable Quantity (RQ), 1000 lb (454 kg) [*per CWA, Sec. 311 (b)(4)&CWA, Sec. 307 (a)]Section 8. Special Protection Data .Go&s: Wear protective eyeglasses or chemical safety goggles. per OSHA eye- <strong>and</strong> face-pmtection regulations (29 CFR 1910.133). Becausecontact lens use in industry is controversial. atablish your own policy. Respirator: Seek professional advice prior to selection <strong>and</strong> use. FollowDSHA respiratoregulations (29 CFR 1910.134) <strong>and</strong>, if necessary, wear a MSHAINIOSH-approved respirator. For < 1000 ppm. use a poweredair-purifyiig respirator with an appropriate organic vapor cartridge, a supplied-air respirator (SAR). SCBA, or chemical cartridge respirator withappropriate organic vapor cartridge. For < 2000 ppm, use a SAR or SCBA with a full facepiece. For emergency or nonroutine operations (cleaningspdls. reactor vessels, or storage tanks), wear an SCBA. Waming! Air-purifying respiratq~ do not protect <strong>work</strong>ers in oxysm-dcficimr o~no-@.eres. If respirators are used, OSHA requires a respiratory protection program that includes at least: medical certification, training. fit-testing.periodic environmental monitoring. maintenance. inspection, cleaning, <strong>and</strong> convenient, sanitary storage areas. Other: Wear chemically pmtectivegloves, boots. aprons. <strong>and</strong> gauntlets made of Viton or polyvinylchloridc to prevent skin contact. Ventilation: Rovide general <strong>and</strong> local exhaustventilation systems to maintain airborne concentrations below the OSHA PELP (Sec. 2). Local exhaust ventilation is preferred because it preventscontaminant dispersion into the <strong>work</strong> area by controlling it at its source. (‘03) Safety Stations: Make available in the <strong>work</strong> area emergencyayewash stations. safety/quick-drench showers, <strong>and</strong> washing facilities. Contaminated Equipment: Separate contaminated <strong>work</strong> clothes fromstreet clothes <strong>and</strong> launder be<strong>for</strong>e reuse. Remove this material Born your shoes <strong>and</strong> clean PPE. Comments: Never eat. drink. or smoke in <strong>work</strong>areas. Fractice good personal hygiene after using this material. especially be<strong>for</strong>e eating, drinking, smoking, using the toilet. or applying cosmetics.Section 9. Special Precautions <strong>and</strong> CommentsStorage Requirements: Store m a cool, dry. well-ventilated area away from ignition sources <strong>and</strong> oxidii. Outside or detatched storage ispreferred. If inside, store in a st<strong>and</strong>ard flammable liquids cabinet Containershould have flame-arrester or pressure-vacuum venting. To preventstatic sparks, electrically ground <strong>and</strong> bond all equipment used with ethylbenxene. Install Class 1. Group D electrical equipment. EngineeringControls: To duce potential health hazards. use sufficient dilution or local exhaust ventilation to control airborne contaminants <strong>and</strong> to maintainlevels as low as possible. Purge <strong>and</strong> ventilate reaction vessels be<strong>for</strong>e <strong>work</strong>ers are allowed to enter <strong>for</strong> maintenance or cleanup. AdministrativeControls: Consider preplacement <strong>and</strong> periodic medical exams of exposed <strong>work</strong>ers that emphasize the CNS, skin. blood <strong>and</strong> respiratory system.Transport&on Date (49 CFR 172JOl)DOT Shipping Name: Ethylbenzene Peckaging Authorizations Quantity LimitationsDOT Hazard Class: 3 a) Rxceptionr 173.150 a) Passenger Aircraft or Railcar: 5LIp No.: UN1175 b) Non-bulk Packaging: 173.202 b) Cergo Aircraft Only: 60 LIT Packing Group: II c) Bulk Packaging: 173.242 Vessel Stowage RequirementsT Label: Flammable liquid_a). .Vessel-_.Stowage: B+ecial Provisions (172.102): Tl D)UtDec: -MSDS Cofkcfion R~~~IWMXS: 26.73. 100. 101.103, 124. 126.127,132. 133,136. 139,140, 148, 153, 159,162163, 164,167,16& 171. 176, 179&pad by: M Gmof~ BA; IndPrtrisl Hygicue R&W: D Wilson, CIH: Mdid Review: W Silverm;ra. MD

- Page 1 and 2:

NOHM RemediationServices Corp.WORK

- Page 3 and 4:

1.0 INTRODUCTIONThis Work Plan (WP)

- Page 5 and 6:

2.0 SITE BACKGROUNDMCB Camp Lejeune

- Page 7 and 8:

..;/II'. 1i4\..\1 '*.XCAVATION \.AR

- Page 9 and 10:

A I B I CE I PI 0 I H I IPARK I NGA

- Page 11 and 12:

OHM RemediationServices Corp. WORK

- Page 13 and 14:

5.0 SITE CONTROL PLANSOHM will impl

- Page 15 and 16:

L= THE DISTANCE SUCH THAT POINTA AN

- Page 17 and 18:

OHM RemediationServices Corp. WORK

- Page 19:

OHMRemediationServices Corp. WORK P

- Page 22 and 23:

OHM RemediationServices Corp. WORK

- Page 24 and 25:

OHM RemediationServices Corp. WORK

- Page 26 and 27:

7.0 SITE RESTORATION AND DEMOBILIZA

- Page 28 and 29:

9.0 PROJECT SCHEDULEThe project sch

- Page 30 and 31:

NOHM RemediationServices Corp.SAMPL

- Page 32 and 33:

TABLE OF CONTENTS - CONTINUED6.0 DA

- Page 34 and 35:

2.0 PROJECT MANAGEMENT2.1 Project B

- Page 36 and 37:

Program ManagerG. Krauter, P.E.Prog

- Page 38 and 39:

OHM RemediationServices Corp. SAMPL

- Page 40 and 41:

OHM RemediationServices Corp. SAMPL

- Page 42 and 43:

OHM RemediationServices Corp. SAMPL

- Page 44 and 45:

OHM RemediationServices Corp. SAMPL

- Page 46 and 47:

OHM RemediationServices Corp. SAMPL

- Page 48 and 49:

A I 8 I P I 0 I EFI I 6 IH1 IPARKIN

- Page 50 and 51:

OHM RemediationServices Corp. SAMPL

- Page 52 and 53:

OHM RemediationServices Corp. SAMPL

- Page 54 and 55:

OHM RemediationServices Corp. SAMPL

- Page 56 and 57:

OHM RemediationServices Corp. SAMPL

- Page 58 and 59:

4.0 DATA ACQUISITION4.1 Analytical

- Page 60 and 61:

OHMRemediationl QC samples are with

- Page 62 and 63:

OHM RemediationServices Corp. SAMPL

- Page 64 and 65:

OHM RemediationServices Corp. SAMPL

- Page 66 and 67:

OHM RemediationServices Corp. SAMPL

- Page 68 and 69:

OHM RemediationServices Corp. SAMPL

- Page 70 and 71:

lWorking order of instruments and e

- Page 72 and 73:

8.0 CORRECTIVE ACTIONCorrective act

- Page 74 and 75:

OHM RemediationServices Corp. SAMPL

- Page 76 and 77:

Table A-lSampling SummarySample Typ

- Page 78 and 79:

Table A-lSampling SummarySample Typ

- Page 80 and 81:

Table A-lSampling SummarySample Typ

- Page 82 and 83:

Table A-lSampling SummarySample Typ

- Page 84 and 85:

Table A-lSampling SummarySample Typ

- Page 86 and 87:

AppendixBSample LabelCustody SealCh

- Page 88 and 89:

3 CHAIN-OF-CUSTODY RECORDOI IM Corp

- Page 90 and 91:

IA== B OHM Renmhtionavices Corp\&FC

- Page 92 and 93:

BOHM RemediationServices Corp.SITE-

- Page 94 and 95:

TABLE OF CONTENTS - CONTINUED6.0 DE

- Page 96 and 97:

This Health and Safety Plan (HASP)

- Page 98 and 99:

_OHM RemediationServices Corp. HEAL

- Page 100 and 101:

OHM RemediationServices Corp. HEALT

- Page 102 and 103:

OHM RemediationServices Corp. HEALT

- Page 104 and 105:

OHM RemediationServices Corp. HEALT

- Page 106 and 107:

OHM RemediationServices Corp. HEALT

- Page 108 and 109:

OHM RemediationServices Corp. HEALT

- Page 110 and 111:

OHM RemediationServices Corp. HEALT

- Page 112 and 113:

OHM RemediationServices Corp. HEALT

- Page 114 and 115:

OHMRemediationconnection between th

- Page 116 and 117:

OHM RemediationServices Corp. HEALT

- Page 118 and 119:

OHMRemediationTask No. 4: SoilSampl

- Page 120 and 121:

OHM RemediationServices Corp. HEALT

- Page 122 and 123: OHM RemediatioaServices Corp. HEALT

- Page 124 and 125: 5.0 PROTECTIVE EQUIPMENTThis sectio

- Page 126 and 127: OHM RemediationServices Corp. HEALT

- Page 128 and 129: 6.0 DECONTAMINATION PROCEDURESThis

- Page 130 and 131: . . . --..7.0 AIR MONITORINGAir mon

- Page 132 and 133: OHM RemediationServices Corp. HEALT

- Page 134 and 135: OHM RemediationServices Corp. HEALT

- Page 136 and 137: OHM RemediationServices Corp. HEALT

- Page 138 and 139: OHM RemediationServices Corp. HEALT

- Page 140 and 141: OHM RemediationServices Corp. HEALT

- Page 142 and 143: OHMRemediationServices Corp. HEALTH

- Page 144 and 145: OHM RemediationServices Corp. HEALT

- Page 146 and 147: OHM RemediationServices Corp. HEALT

- Page 148 and 149: OHM RemediationServices Corp. HEALT

- Page 150 and 151: ci@- OHM RemediationServices Corp.

- Page 152 and 153: 9.0 TRAINING REQUIREMENTSAs a prere

- Page 154 and 155: OHM RemediationServices Corp. HEALT

- Page 156 and 157: HEALTH-AND-SAFETYPLAN CERTlFICATION

- Page 158 and 159: APPENDIX B - OHM HAZARD COMMUNICATI

- Page 160 and 161: 8. Know what you are expected to do

- Page 162 and 163: . Methods and observations that may

- Page 164 and 165: msPhysical propertiesAcute/Chronic

- Page 166 and 167: GPI Material Safety Data Sheets Col

- Page 168 and 169: Material Safety Data Sheets Collect

- Page 170 and 171: e5P (518)37%8854Genium Publishing C

- Page 174 and 175: Material Safety Data Sheets Collect

- Page 176 and 177: Genium Publishing CorporationMateri

- Page 178 and 179: I, r.___Genium Publishing Corporati

- Page 180 and 181: e.- -- _ - ------ -._-___ --._ ---.

- Page 182 and 183: .UrRPLS= ?UXiURE OF PARAFFIHTC, CTt

- Page 184 and 185: APPxavg a5twfIc vAPUR'C!fE?!XCAL CA

- Page 186 and 187: Fi reNF?A HAZARD RATING ’- Extten

- Page 188 and 189: WITCO MATERIAL SAFETY .O A T A SHEE

- Page 190: . .c . ._. . . .. . . .# . . .. . .

- Page 193 and 194: 0.i1 -.-0.’ ,,’. .,‘A .,-“.

- Page 195 and 196: IX Fhysial OataSan’ag,de.. ......

- Page 197 and 198: -. - _ ___-. ----_-INGEzcizuIi tngu

- Page 199 and 200: ---------w.- -- ----F. FWSICAL DATA

- Page 201 and 202: ---.

- Page 203 and 204: SECTION 5c- HEALTH HAZAROS4lllmsnol

- Page 205 and 206: .--‘ AMALIE MULTI-PURPOSE LS GEAR

- Page 207 and 208: We believe the statements, technica

- Page 209 and 210: (Section III cmtinuei,)ffcsk=sint:

- Page 211 and 212: ““. m-. -I a-. -- ---- --- ----

- Page 213 and 214: i:.:::;:. ..-., \,’. .No. 68 Calc

- Page 215 and 216: HATZ:P~A&,SXFETY DATA SHEET NC?. CO

- Page 217 and 218: .w.N/AHAZAROOUS MIXTURES OF OTHER L

- Page 219 and 220: .._ s1\1a.lZPage 4CHEMICAL FORMULA:

- Page 221 and 222: . .SECTION 6. HEXLTH HAZARD. IfiFOR

- Page 223 and 224:

AJ 0. 14MSDS No. 324 Isopropyl Alco

- Page 225 and 226:

No. 14MSDS No. 324 Isopropyl Alcoho

- Page 227 and 228:

.;, -.-:-..: ..INo.44 Methane 8A9__

- Page 229:

. Materiaf Safety Data SheetFrom Gc

- Page 232 and 233:

:.I3 FlRsrBRANDSMaterial Safety Dat

- Page 234 and 235:

.nFIRSTBRANDSMaterial Safety Data S

- Page 236 and 237:

.. . DFIRSTBRANIlSMaterial Safety D

- Page 238 and 239:

Tdeshone:Infomation: (619) 275liu~C

- Page 240 and 241:

APPENDIXDHEALTH AND SAFETY FORMSAcc

- Page 242 and 243:

(Use Extra Pageif Needed).--%scribo

- Page 244 and 245:

*c= OH31 Remediation\m Services Cor

- Page 246 and 247:

IBAR MONTHLY INSbBCTIONCHECRLIBTBAR

- Page 248 and 249:

alme,-I sowica Corp.COMBUS’ITBLE

- Page 250 and 251:

DIRECT READING INSTUMENT LOGNAME:PR

- Page 252 and 253:

j% - -5 mi -omcorpo~Date:DAILY SA.F

- Page 254 and 255:

. ‘ISCUA MONIIILY INSFECA'ION CIi

- Page 256 and 257:

SITE SAFETY OFFICERDAILY REPORTDATE

- Page 258 and 259:

~.-’ - . .-Pm-.. -d-e..-L ArtEre

- Page 260 and 261:

----------t.------------m----------

- Page 262 and 263:

HAZARD ANALYSISEM 38s i1 Ott 92nLll