- Page 1 and 2:

Report to: Wellgreen Project Prelim

- Page 3 and 4:

TABLE OF CONTENTS 1.0 SUMMARY .....

- Page 5 and 6:

14.1.8 MINERAL RESOURCE TABULATION

- Page 7 and 8:

26.1.2 PHASE 2 - QUILL CREEK ULTRAM

- Page 9 and 10:

Table 19.2 Palladium Demand and Sup

- Page 11 and 12:

Figure 19.3 London Metals Exchange

- Page 13 and 14:

litres per minute .................

- Page 15 and 16:

International All-North Resources L

- Page 17 and 18:

1.0 S UMMARY 1.1 I NTRODUCTION Tetr

- Page 19 and 20:

This PEA has been prepared by Tetra

- Page 21 and 22:

Numerous operators have worked on t

- Page 23 and 24:

1.6 M INING M ETHODS The Project is

- Page 25 and 26:

Figure 1.2 Wellgreen Project Overal

- Page 27 and 28:

Table 1.6 Capital Cost Summary (US$

- Page 29 and 30:

The following financial results wer

- Page 31 and 32:

Figure 1.3 illustrates that the Pro

- Page 33 and 34:

Figure 1.5 Project Execution Plan P

- Page 35 and 36:

2.0 INTRODUCTION Tetra Tech was com

- Page 37 and 38:

3.0 RELIANCE ON OTHER EXPERTS Tetra

- Page 39 and 40:

Figure 4.1 Location Map Prophecy Pl

- Page 41 and 42:

All work undertaken on the surface

- Page 43 and 44:

Figure 4.3 Wellgreen Surface Lease

- Page 45 and 46:

Other than those liabilities set fo

- Page 47 and 48:

5.3 C LIMATE The climate is alpine,

- Page 49 and 50:

Year Company Activities 1970 Hudson

- Page 51 and 52:

Year Company Activities 2008 Corona

- Page 53 and 54:

6.2.3 NORTHERN P LATINUM 2009 PROGR

- Page 55 and 56:

Figure 7.1 Regional Geology Map Pro

- Page 57 and 58:

Figure 7.3 Property Geology Prophec

- Page 59 and 60:

Longitudinal faults and/or shears a

- Page 61 and 62:

Figure 7.4 Wellgreen Plan View Prop

- Page 63 and 64:

7.2.3 NORTH ZONE The North Zone is

- Page 65 and 66:

Table 7.3 PGE-Bearing Minerals in t

- Page 67 and 68:

Gabbroid-associated Nickel, Copper,

- Page 69 and 70:

10.0 DRILLING 10.1 H ISTORICAL D RI

- Page 71 and 72:

Figure 10.1 Prophecy Platinum Drill

- Page 73 and 74:

Table 10.4 Prophecy Platinum 2011 D

- Page 75 and 76:

• The course rejects returned fro

- Page 77 and 78:

Figure 10.4 Core Storage Facility P

- Page 79 and 80:

11.0 SAMPLE PREPARATION, ANALYSES,

- Page 81 and 82:

12.0 DATA VERIFICATION Tetra Tech

- Page 83 and 84:

Table 12.2 Check Assays Prophecy Pl

- Page 85 and 86:

13.0 MINERAL PROCESSING AND METALLU

- Page 87 and 88:

An elemental analysis of typical co

- Page 89 and 90:

Minerals Peridotite Composite 1 Min

- Page 91 and 92:

Ni Deposits” shows that the grade

- Page 93 and 94:

13.3 SGS V ANCOUVER - J UNE 2012 A

- Page 95 and 96:

14.0 MINERAL RESOURCE ESTIMATES 14.

- Page 97 and 98:

Table 14.3 summarizes the grade cap

- Page 99 and 100: The NiEq value was assigned to all

- Page 101 and 102: Table 14.7 Wellgreen Variogram Summ

- Page 103 and 104: Table 14.9 Estimation Criteria Zone

- Page 105 and 106: Table 14.10 Search Parameters Zone

- Page 107 and 108: NiEq Cut-off Tonnes NiEq (%) Ni (%)

- Page 109 and 110: Figure 14.2 Wellgreen Platinum, Pal

- Page 111 and 112: Figure 14.4 Wellgreen Platinum, Pal

- Page 113 and 114: Figure 14.6 Wellgreen Pit Resource

- Page 115 and 116: 14.1.9 VALIDATION The Wellgreen mod

- Page 117 and 118: Figure 14.9 East Zone Cross Section

- Page 119 and 120: Figure 14.10 Wellgreen Nickel Secti

- Page 121 and 122: Figure 14.14 Wellgreen Platinum Sec

- Page 123 and 124: Figure 14.18 Wellgreen Cobalt Eleva

- Page 125 and 126: 14.2 P REVIOUS E STIMATES Table 14.

- Page 127 and 128: 15.0 MINERAL RESERVE ESTIMATES A mi

- Page 129 and 130: The selected base case pit contains

- Page 131 and 132: OVERALL O PEN P IT SLOPE ANGLE Tetr

- Page 133 and 134: Table 16.4 Pit Optimization Results

- Page 135 and 136: The pit optimization process includ

- Page 137 and 138: 16.4 P RODUCTION S CHDULE Using Pit

- Page 139 and 140: Year Waste (t) Total (t) Strip Rati

- Page 141 and 142: Figure 16.5 Sequence of Development

- Page 143 and 144: PHASE III During Phase III, the pit

- Page 145 and 146: 16.5.4 EXPLOSIVES A contractor will

- Page 147 and 148: Table 16.9 Pit Design Criteria Item

- Page 149: Equipment Fleet Size Units Crew Bus

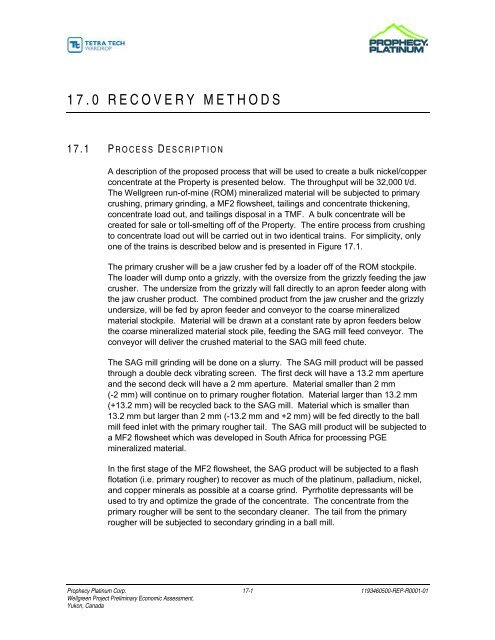

- Page 153 and 154: 17.2 P ROCESS D ESIGN C RITERIA The

- Page 155 and 156: 17.5 P ROCESS P LANT The process pl

- Page 157 and 158: Figure 18.1 Wellgreen Project Overa

- Page 159 and 160: ultimate impoundment surface area o

- Page 161 and 162: Table 19.2 Palladium Demand and Sup

- Page 163 and 164: Figure 19.3 London Metals Exchange

- Page 165 and 166: Figure 19.5 Nickel Demand (2009 to

- Page 167 and 168: 20.0 ENVIRONMENTAL STUDIES, PERMITT

- Page 169 and 170: Tailings and mill concentrate sampl

- Page 171 and 172: 20.2.4 AQUATIC RESOURCES The Proper

- Page 173 and 174: Figure 20.2 Wildlife Ranges-Woodlan

- Page 175 and 176: Figure 20.4 Wildlife Ranges-Mountai

- Page 177 and 178: Figure 20.6 Wildlife Ranges-Grizzly

- Page 179 and 180: Figure 20.8 Aquatic Resources Proph

- Page 181 and 182: 20.3.2 LICENSING The Project will b

- Page 183 and 184: (Transport Canada 2010). New constr

- Page 185 and 186: Table 20.1 Applicable Legislation,

- Page 187 and 188: 20.4 M I NE C LOSURE AND R ECLAMATI

- Page 189 and 190: Umbrella Final Agreement, the White

- Page 191 and 192: 20.5.2 NON-ABORIGINAL COMMUNITIES T

- Page 193 and 194: 21.0 C APITAL AND O PERATING C OSTS

- Page 195 and 196: Mine Equipment 21.2.2 SUSTAINING 20

- Page 197 and 198: Table 21.7 Contingency (US$ million

- Page 199 and 200: • mobilization and demobilization

- Page 201 and 202:

Spares • safety including safety

- Page 203 and 204:

21.3 O PERATING C OSTS 21.3.1 GENER

- Page 205 and 206:

Table 21.11 Summary of Mining Opera

- Page 207 and 208:

Mine Operations Position No. Annual

- Page 209 and 210:

22.0 ECONOMIC A NALYSIS 22.1 I NTRO

- Page 211 and 212:

Table 22.3 Metal Production from th

- Page 213 and 214:

Table 22.4 Summary of Pre-tax Finan

- Page 215 and 216:

22.4 M ETAL P RICE S CENARIOS The L

- Page 217 and 218:

Figure 22.3 IRR Sensitivity Analysi

- Page 219 and 220:

Figure 23.1 Adjacent Properties Pro

- Page 221 and 222:

Figure 24.1 Wellgreen Project Execu

- Page 223 and 224:

25.2 M INING Table 25.1 Wellgreen R

- Page 225 and 226:

Table 25.4 Process Capital Cost Sum

- Page 227 and 228:

Table 26.1 Wellgreen Expansion Budg

- Page 229 and 230:

26.2 M INING sample selection shoul

- Page 231 and 232:

Trade-off studies should be complet

- Page 233 and 234:

• develop a negotiation strategy

- Page 235 and 236:

METALLURGY Davis, David and Bruwer,

- Page 237 and 238:

Yukon Environmental and Socio-econo

- Page 239 and 240:

TODD MCCRACKEN, P.GEO. I, Todd McCr

- Page 241 and 242:

PHILIP BRIDSON, P.ENG. I, Philip Br

- Page 243 and 244:

APPENDIX A L IST OF C LAIMS

- Page 245 and 246:

District GrantNumber RegType ClaimN

- Page 247 and 248:

District GrantNumber RegType ClaimN

- Page 249 and 250:

District GrantNumber RegType ClaimN

- Page 256 and 257:

Certificate of Analysis First issue

- Page 258 and 259:

Hf µg/g 0.5 4 / 20 Ho µg/g 0.2 3

- Page 260 and 261:

assess laboratory results, users ar

- Page 262 and 263:

Constituent Unit Mean Table 2 - Pro

- Page 264 and 265:

Table 3 - Informational Values Cons

- Page 266 and 267:

CERTIFYING OFFICER ________________

- Page 268 and 269:

An Investigation into METALLURGICAL

- Page 270 and 271:

Prophecy Platinum Corporation - Wel

- Page 272 and 273:

Prophecy Platinum Corporation - Wel

- Page 274 and 275:

Prophecy Platinum Corporation - Wel

- Page 276 and 277:

Prophecy Platinum Corporation - Wel

- Page 278 and 279:

Prophecy Platinum Corporation - Wel

- Page 280 and 281:

Sample Fraction Mass Size Distribut

- Page 282 and 283:

Mass (% Chalcopyrite) Prophecy Plat

- Page 284 and 285:

Mass (% Pentlandite) Prophecy Plati

- Page 286 and 287:

Mass (% Pyrrhotite) Prophecy Platin

- Page 288 and 289:

Prophecy Platinum Corporation - Wel

- Page 290 and 291:

Pyrrhotite Recovery % Prophecy Plat

- Page 292 and 293:

Prophecy Platinum Corporation - Wel

- Page 294 and 295:

Prophecy Platinum Corporation - Wel

- Page 296 and 297:

Prophecy Platinum Corporation - Wel

- Page 298 and 299:

Cu Rec, % Ni Rec, % Gng Rec, % 100

- Page 300 and 301:

Prophecy Platinum Corporation - Wel

- Page 302 and 303:

Prophecy Platinum Corporation - Wel

- Page 304 and 305:

Prophecy Platinum Corporation - Wel

- Page 306 and 307:

Prophecy Platinum Corporation - Wel

- Page 308 and 309:

Prophecy Platinum Corporation - Wel

- Page 310 and 311:

Grade (%) Cu + Ni Grade (g/t) PGE G

- Page 312 and 313:

Prophecy Platinum Corporation - Wel

- Page 314 and 315:

Prophecy Platinum Corporation - Wel

- Page 316 and 317:

Prophecy Platinum Corporation - Wel

- Page 318 and 319:

Prophecy Platinum Corporation - Wel

- Page 320 and 321:

Prophecy Platinum Corporation - Wel

- Page 322 and 323:

Prophecy Platinum Corporation - Wel

- Page 324 and 325:

Prophecy Platinum Corporation - Wel

- Page 326 and 327:

Prophecy Platinum Corporation - Wel

- Page 328 and 329:

Prophecy Platinum Corporation - Wel

- Page 330 and 331:

Prophecy Platinum Corporation - Wel

- Page 332 and 333:

Prophecy Platinum Corporation - Wel

- Page 334 and 335:

Prophecy Platinum Corporation - Wel

- Page 336 and 337:

Prophecy Platinum Corporation - Wel

- Page 338 and 339:

Prophecy Platinum Corporation - Wel

- Page 340 and 341:

Prophecy Platinum Corporation - Wel

- Page 342 and 343:

Prophecy, Wellgreen samples 50149-0

- Page 344 and 345:

OnLine LIMS SGS Lakefield Research

- Page 346 and 347:

OnLine LIMS SGS Lakefield Research

- Page 348 and 349:

Certificate of Analysis Work Order:

- Page 350 and 351:

Final : VC120756 Revision REVISED O

- Page 352 and 353:

Final : VC120756 Revision REVISED O

- Page 354 and 355:

Final : VC120590A Revision REVISED

- Page 356 and 357:

Final : VC120590 Revision REVISED O

- Page 358 and 359:

Final : VC120590 Revision REVISED O

- Page 360 and 361:

Final : VC120590 Revision REVISED O

- Page 362 and 363:

OnLine LIMS SGS Lakefield Research

- Page 364 and 365:

SGS Minerals Services Standard Bond

- Page 366 and 367:

Project No.: 50149-001 Test No.: MC

- Page 368 and 369:

SGS Minerals Services STANDARD BOND

- Page 370 and 371:

SGS Minerals Services Project No. D

- Page 372 and 373:

SGS Minerals Services Project No. D

- Page 374 and 375:

SGS Minerals Services Project No. D

- Page 376 and 377:

Test No.: F1 Project No.: 50149-001

- Page 378 and 379:

Test No.: F3 Project No.: 50149-001

- Page 380 and 381:

Test No.: F5 Project No.: 50149-001

- Page 382 and 383:

Test No.: F7 Project No.: 50149-001

- Page 384 and 385:

Test No.: F9 Project No.: 50149-001

- Page 386 and 387:

Test No.: F11 Project No.: 50149-00

- Page 388 and 389:

Test No.: F13 Project No.: 50149-00

- Page 390 and 391:

Test No.: F15 Project No.: 50149-00

- Page 392 and 393:

Test No.: F17 Project No.: 50149-00

- Page 394 and 395:

Test No.: Sep-F1 Project No.: 50149

- Page 396 and 397:

Test No.: F20 Project No.: 50149-00

- Page 398 and 399:

Test No.: F22 Project No.: 50149-00

- Page 400 and 401:

Test No.: F24 Project No.: 50149-00

- Page 402 and 403:

Test No.: F26 Project No.: 50149-00

- Page 404 and 405:

Test No.: F28 Project No.: 50149-00

- Page 406 and 407:

Test: F30 Project: 11603-005 50149-

- Page 408 and 409:

Test: F32 Project: 11603-005 50149-

- Page 410 and 411:

Test: F34 Project: 11603-005 50149-

- Page 412 and 413:

Test: F36 Project: 11603-005 50149-

- Page 414 and 415:

Test: F38 Project: 11603-005 50149-

- Page 416 and 417:

Test No.: F40 Project No.: 50149-00

- Page 418 and 419:

Test No.: HNI-F1 Project No.: 50149

- Page 420 and 421:

Test: HNI-F3 Project: 11603-005 501

- Page 422 and 423:

Test: HNI-F5 Project: 11603-005 501

- Page 424 and 425:

Test: LCT-1 Project: 50149-001 Date

- Page 426 and 427:

Test: LCT-1 Overall Stability Total

- Page 428 and 429:

Test: LCT-2 Metallurgical Predictio

- Page 430 and 431:

Test: LCT-3 Metallurgical Predictio

- Page 432 and 433:

Test: LCT-4 Project: 50149-001 Date

- Page 434 and 435:

Test: LCT-4 Overall Stability Total

- Page 436 and 437:

Test: LCT-5 Metallurgical Predictio

- Page 438 and 439:

Prophecy Platinum Corporation - Wel

- Page 440 and 441:

Prophecy Platinum Corp 50149-101 MI

- Page 442 and 443:

Prophecy Platinum Corp 50149-101 MI

- Page 444 and 445:

Prophecy Platinum Corp 50149-101 MI

- Page 446 and 447:

Prophecy Platinum Corp 50149-101 MI

- Page 448 and 449:

Prophecy Platinum Corp 50149-101 MI

- Page 450 and 451:

Prophecy Platinum Corp 50149-101 MI

- Page 452 and 453:

Prophecy Platinum Corp 50149-101 MI

- Page 454 and 455:

Prophecy Platinum Corp 50149-101 MI

- Page 456 and 457:

Prophecy Platinum Corp 50149-101 MI

- Page 458 and 459:

Prophecy Platinum Corp 50149-101 MI

- Page 460 and 461:

Prophecy Platinum Corp 50149-101 MI

- Page 462 and 463:

Prophecy Platinum Corp 50149-101 MI

- Page 464 and 465:

Prophecy Platinum Corp 50149-101 MI

- Page 466 and 467:

Prophecy Platinum Corp 50149-101 MI

- Page 468 and 469:

Prophecy Platinum Corp 50149-101 MI

- Page 470 and 471:

Prophecy Platinum Corp 50149-101 MI

- Page 472 and 473:

Mineral Abundance (wt.%) 100 90 80

- Page 474 and 475:

Prophecy Platinum Corp 50149-101 MI

- Page 476 and 477:

Prophecy Platinum Corp 50149-101 MI

- Page 478 and 479:

Page 10 of 23

- Page 480 and 481:

Prophecy Platinum Corp 50149-101 MI

- Page 482 and 483:

Prophecy Platinum Corp 50149-101 MI

- Page 484 and 485:

Page 16 of 23

- Page 486 and 487:

Prophecy Platinum Corp 50149-101 MI

- Page 488 and 489:

Prophecy Platinum Corp 50149-101 MI

- Page 490 and 491:

Prophecy Platinum Corp 50149-101 MI

- Page 492 and 493:

CAVM-50149-101 MI7018-MAR12 Sample

- Page 494 and 495:

CAVM-50149-101 MI7018-MAR12 Sample

- Page 496 and 497:

erra Mineralogical Services Inc. Mi

- Page 498 and 499:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 500 and 501:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 502 and 503:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 504 and 505:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 506 and 507:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 508 and 509:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 510 and 511:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 512 and 513:

TerraMS-12JUL-001 Wellgreen - Pt-Pd

- Page 514 and 515:

APPENDIX D M INING

- Page 516 and 517:

LG Phase Revenue Factor (%) Mineral

- Page 518 and 519:

Figure 3 Overall Ultimate Pit Produ

- Page 520 and 521:

Table 3 Penetration and Drilling Ra

- Page 522 and 523:

HAULAGE General Hauling Conditions

- Page 524:

Year Mechanical Availability (%) Us