Wellgreen Project Preliminary Economic Assessment ... - OTCIQ.com

Wellgreen Project Preliminary Economic Assessment ... - OTCIQ.com

Wellgreen Project Preliminary Economic Assessment ... - OTCIQ.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Prophecy Platinum Corporation – <strong>Wellgreen</strong> Property – <strong>Project</strong> 50149-001<br />

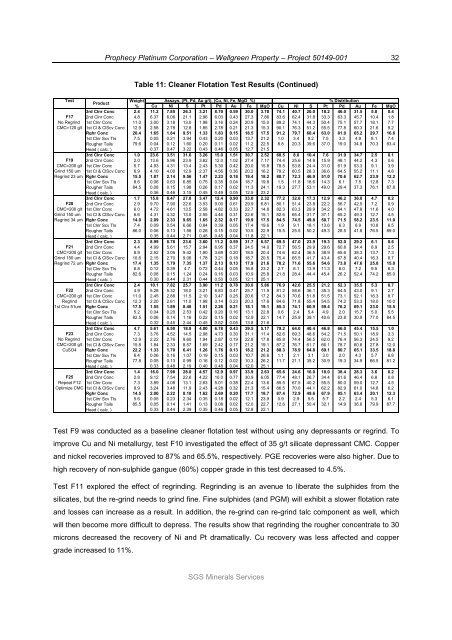

Table 11: Cleaner Flotation Test Results (Continued)<br />

Test<br />

Product<br />

Weight<br />

% Cu<br />

Assays, (Pt, Pd, Au g/t), (Cu, Ni, Fe, MgO %)<br />

Ni S Pt Pd Au Fe MgO Cu Ni<br />

% Distribution<br />

S Pt Pd Au Fe MgO<br />

3rd Clnr Conc 2.4 11.2 7.85 26.3 3.21 8.70 0.59 30.0 3.70 74.1 40.7 20.0 18.2 46.0 31.5 5.8 0.4<br />

F17 2nd Clnr Conc 4.8 6.37 6.06 21.1 2.96 6.03 0.43 27.3 7.86 83.6 62.4 31.8 33.3 63.3 45.7 10.4 1.8<br />

No Regrind 1st Clnr Conc 11.0 3.00 3.18 13.0 1.98 3.16 0.24 20.9 15.0 89.2 74.1 44.3 50.4 75.1 57.7 18.1 7.7<br />

CMC=120 g/t 1st Cl & ClScv Conc 12.9 2.58 2.78 12.8 1.85 2.78 0.21 21.3 15.3 90.1 76.3 51.2 55.5 77.8 60.3 21.6 9.2<br />

Rghr Conc 20.4 1.65 1.84 9.51 1.33 1.83 0.15 18.5 17.5 91.2 79.7 60.4 63.0 81.0 65.2 29.7 16.6<br />

1st Clnr Scv Tls 7.5 0.05 0.21 3.94 0.43 0.20 0.03 13.7 21.2 1.0 3.4 9.2 7.5 3.3 4.9 8.1 7.4<br />

Rougher Tails 79.6 0.04 0.12 1.60 0.20 0.11 0.02 11.2 22.5 8.8 20.3 39.6 37.0 19.0 34.8 70.3 83.4<br />

Head ( calc. ) 0.37 0.47 3.22 0.43 0.46 0.05 12.7 21.5<br />

3rd Clnr Conc 1.0 23.6 3.51 31.6 3.26 15.0 1.51 30.7 2.52 68.5 8.0 10.4 7.6 31.9 34.7 2.5 0.1<br />

F19 2nd Clnr Conc 2.0 13.6 5.96 23.9 3.62 12.0 1.02 27.4 7.17 74.4 25.6 14.9 15.9 48.1 44.2 4.3 0.6<br />

CMC=200 g/t 1st Clnr Conc 5.7 4.93 4.31 13.4 2.43 5.30 0.42 20.0 15.8 78.5 53.8 24.4 31.0 61.9 53.3 9.1 3.9<br />

Grind 150 um 1st Cl & ClScv Conc 6.9 4.10 4.00 12.9 2.37 4.56 0.36 20.2 16.2 79.2 60.5 28.3 36.6 64.5 55.2 11.1 4.8<br />

Regrind 23 um Rghr Conc 15.5 1.87 2.14 9.56 1.47 2.23 0.18 19.4 18.2 80.7 72.3 46.9 51.0 70.6 62.7 23.9 12.2<br />

1st Clnr Scv Tls 8.6 0.06 0.63 6.85 0.75 0.35 0.04 18.7 19.8 1.5 11.8 18.6 14.3 6.1 7.5 12.8 7.3<br />

Rougher Tails 84.5 0.08 0.15 1.98 0.26 0.17 0.02 11.3 24.1 19.3 27.7 53.1 49.0 29.4 37.3 76.1 87.8<br />

Head ( calc. ) 0.36 0.46 3.15 0.45 0.49 0.05 12.5 23.2<br />

3rd Clnr Conc 1.7 15.8 8.47 27.8 3.47 12.4 0.90 33.0 2.32 77.2 32.6 17.3 12.9 46.2 36.8 4.7 0.2<br />

F20 2nd Clnr Conc 2.9 9.70 7.90 22.6 3.53 9.00 0.61 29.9 6.81 80.1 51.4 23.8 22.2 56.7 42.5 7.2 0.9<br />

CMC=200 g/t 1st Clnr Conc 6.0 4.72 4.61 13.5 2.58 4.82 0.33 22.7 14.8 82.3 63.3 29.9 34.2 64.1 47.8 11.6 4.0<br />

Grind 150 um 1st Cl & ClScv Conc 6.6 4.31 4.32 13.0 2.55 4.46 0.31 22.6 15.1 82.6 65.4 31.7 37.1 65.2 49.3 12.7 4.5<br />

Regrind 34 um Rghr Conc 14.0 2.09 2.33 9.65 1.65 2.32 0.17 19.9 17.5 84.5 74.5 49.8 50.7 71.5 58.2 23.5 11.0<br />

1st Clnr Scv Tls 7.4 0.09 0.54 6.66 0.84 0.39 0.05 17.4 19.6 1.9 9.1 18.1 13.6 6.3 8.9 10.8 6.5<br />

Rougher Tails 86.0 0.06 0.13 1.58 0.26 0.15 0.02 10.5 22.9 15.5 25.5 50.2 49.3 28.5 41.8 76.5 89.0<br />

Head ( calc. ) 0.35 0.44 2.71 0.45 0.45 0.04 11.8 22.1<br />

3rd Clnr Conc 2.3 8.99 8.78 23.6 3.60 11.2 0.59 31.7 6.57 69.5 47.0 23.9 19.3 52.0 29.2 6.1 0.6<br />

F21 2nd Clnr Conc 4.4 4.99 5.61 15.7 2.94 6.95 0.37 24.5 14.0 72.7 56.5 29.9 29.6 60.8 34.4 8.9 2.5<br />

CMC=200 g/t 1st Clnr Conc 8.9 2.52 3.05 9.42 1.90 3.69 0.20 18.5 20.4 74.6 62.4 36.5 38.9 65.6 38.3 13.7 7.3<br />

Grind 150 um 1st Cl & ClScv Conc 10.6 2.15 2.70 9.06 1.78 3.21 0.18 18.7 20.5 75.4 65.5 41.7 43.4 67.8 40.4 16.3 8.7<br />

Regrind 72 um Rghr Conc 17.4 1.35 1.79 7.35 1.37 2.13 0.13 17.9 21.6 78.2 71.6 55.6 54.6 73.8 47.6 25.8 15.0<br />

1st Clnr Scv Tls 6.8 0.12 0.39 4.7 0.72 0.44 0.05 16.8 23.2 2.7 6.1 13.9 11.3 6.0 7.2 9.5 6.3<br />

Rougher Tails 82.6 0.08 0.15 1.24 0.24 0.16 0.03 10.9 25.8 21.8 28.4 44.4 45.4 26.2 52.4 74.2 85.0<br />

Head ( calc. ) 0.30 0.44 2.31 0.44 0.50 0.05 12.1 25.1<br />

3rd Clnr Conc 2.4 10.1 7.82 25.7 3.90 11.2 0.78 30.0 5.86 76.9 42.6 25.5 21.2 52.3 35.5 5.3 0.7<br />

F22 2nd Clnr Conc 4.9 5.28 5.32 18.0 3.21 6.83 0.47 25.7 11.9 81.2 58.6 36.1 35.3 64.5 43.0 9.1 2.7<br />

CMC=200 g/t 1st Clnr Conc 11.0 2.45 2.88 11.5 2.10 3.47 0.25 20.6 17.2 84.3 70.6 51.8 51.5 73.1 52.1 16.3 8.7<br />

Regrind 1st Cl & ClScv Conc 12.3 2.20 2.61 11.0 1.98 3.14 0.23 20.3 17.6 84.6 71.8 55.4 54.5 74.2 53.3 18.0 10.0<br />

1st Clnr 51um Rghr Conc 17.5 1.55 1.89 8.48 1.51 2.26 0.21 18.1 19.1 85.3 74.1 60.9 59.4 76.2 69.1 23.0 15.5<br />

1st Clnr Scv Tls 5.2 0.04 0.20 2.53 0.42 0.20 0.16 13.1 22.8 0.6 2.4 5.4 4.9 2.0 15.7 5.0 5.5<br />

Rougher Tails 82.5 0.06 0.14 1.16 0.22 0.15 0.02 12.9 22.1 14.7 25.9 39.1 40.6 23.8 30.9 77.0 84.5<br />

Head ( calc. ) 0.32 0.45 2.44 0.45 0.52 0.05 13.8 21.6<br />

3rd Clnr Conc 4.7 5.61 6.50 18.8 4.00 6.78 0.43 39.5 5.17 79.2 64.0 40.4 46.8 66.0 45.4 15.5 1.0<br />

F23 2nd Clnr Conc 7.3 3.76 4.52 14.5 2.98 4.73 0.30 31.1 11.4 82.6 69.3 48.6 54.2 71.5 50.1 18.9 3.3<br />

No Regrind 1st Clnr Conc 12.9 2.22 2.76 9.60 1.94 2.87 0.19 22.8 17.8 85.8 74.4 56.5 62.0 76.4 56.3 24.5 9.2<br />

CMC=200 g/t 1st Cl & ClScv Conc 15.8 1.84 2.33 8.57 1.69 2.42 0.17 21.2 19.1 87.2 76.7 61.7 66.1 78.7 60.8 27.8 12.0<br />

CuSO4 Rghr Conc 22.2 1.33 1.70 6.41 1.26 1.76 0.13 18.2 21.2 88.3 78.9 64.8 69.1 80.7 65.1 33.5 18.8<br />

1st Clnr Scv Tls 6.4 0.06 0.16 1.07 0.19 0.15 0.03 10.7 26.6 1.1 2.1 3.1 3.0 2.0 4.3 5.7 6.8<br />

Rougher Tails 77.8 0.05 0.13 0.99 0.16 0.12 0.02 10.3 26.2 11.7 21.1 35.2 30.9 19.3 34.9 66.5 81.2<br />

Head ( calc. ) 0.33 0.48 2.19 0.40 0.48 0.04 12.0 25.1<br />

3rd Clnr Conc 1.4 16.0 7.98 28.0 4.57 12.9 0.97 33.9 2.63 65.6 24.6 16.0 18.0 38.4 28.3 3.6 0.2<br />

F25 2nd Clnr Conc 2.8 9.12 7.54 22.6 4.22 10.0 0.77 30.9 6.05 77.4 48.1 26.7 34.4 61.6 46.4 6.8 0.8<br />

Repeat F12 1st Clnr Conc 7.3 3.89 4.08 13.1 2.63 5.01 0.38 22.4 13.6 85.5 67.5 40.2 55.5 80.0 59.0 12.7 4.5<br />

Optimize CMC 1st Cl & ClScv Conc 8.9 3.24 3.48 11.9 2.43 4.28 0.32 21.3 15.4 86.5 70.0 44.1 62.2 82.9 61.0 14.8 6.2<br />

Rghr Conc 14.5 2.00 2.22 8.18 1.62 2.69 0.20 17.7 18.7 87.4 72.9 49.6 67.9 85.1 63.4 20.1 12.3<br />

1st Clnr Scv Tls 5.6 0.05 0.23 2.34 0.35 0.18 0.02 12.1 23.9 0.9 2.9 5.5 5.7 2.2 2.4 5.3 6.1<br />

Rougher Tails 85.5 0.05 0.14 1.41 0.13 0.08 0.02 12.0 22.7 12.6 27.1 50.4 32.1 14.9 36.6 79.9 87.7<br />

Head ( calc. ) 0.33 0.44 2.39 0.35 0.46 0.05 12.8 22.1<br />

Test F9 was conducted as a baseline cleaner flotation test without using any depressants or regrind. To<br />

improve Cu and Ni metallurgy, test F10 investigated the effect of 35 g/t silicate depressant CMC. Copper<br />

and nickel recoveries improved to 87% and 65.5%, respectively. PGE recoveries were also higher. Due to<br />

high recovery of non-sulphide gangue (60%) copper grade in this test decreased to 4.5%.<br />

Test F11 explored the effect of regrinding. Regrinding is an avenue to liberate the sulphides from the<br />

silicates, but the re-grind needs to grind fine. Fine sulphides (and PGM) will exhibit a slower flotation rate<br />

and losses can increase as a result. In addition, the re-grind can re-grind talc <strong>com</strong>ponent as well, which<br />

will then be<strong>com</strong>e more difficult to depress. The results show that regrinding the rougher concentrate to 30<br />

microns decreased the recovery of Ni and Pt dramatically. Cu recovery was less affected and copper<br />

grade increased to 11%.<br />

SGS Minerals Services<br />

32