User Manual 08/2003 Edition

User Manual 08/2003 Edition

User Manual 08/2003 Edition

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

1 Brief Description 04.01 05.03<br />

1.2 Function overview and differences between 75 W / 300 W<br />

1.2 Function overview and differences between 75 W / 300 W<br />

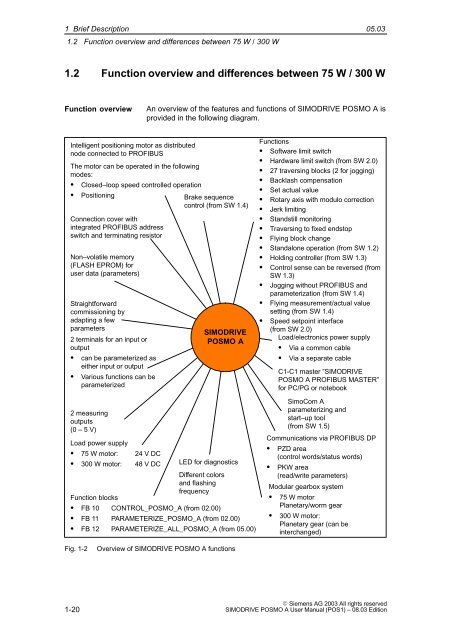

Function overview<br />

Intelligent positioning motor as distributed<br />

node connected to PROFIBUS<br />

The motor can be operated in the following<br />

modes:<br />

Closed–loop speed controlled operation<br />

Positioning<br />

Connection cover with<br />

integrated PROFIBUS address<br />

switch and terminating resistor<br />

Non–volatile memory<br />

(FLASH EPROM) for<br />

user data (parameters)<br />

Straightforward<br />

commissioning by<br />

adapting a few<br />

parameters<br />

2 terminals for an input or<br />

output<br />

can be parameterized as<br />

either input or output<br />

Various functions can be<br />

parameterized<br />

2 measuring<br />

outputs<br />

(0 – 5 V)<br />

1-20<br />

An overview of the features and functions of SIMODRIVE POSMO A is<br />

provided in the following diagram.<br />

Brake sequence<br />

control (from SW 1.4)<br />

SIMODRIVE<br />

POSMO A<br />

Load power supply<br />

75 W motor: 24 V DC<br />

300 W motor: 48 V DC LED for diagnostics<br />

Different colors<br />

and flashing<br />

frequency<br />

Function blocks<br />

FB 10 CONTROL_POSMO_A (from 02.00)<br />

FB 11 PARAMETERIZE_POSMO_A (from 02.00)<br />

FB 12 PARAMETERIZE_ALL_POSMO_A (from 05.00)<br />

Fig. 1-2 Overview of SIMODRIVE POSMO A functions<br />

Functions<br />

Software limit switch<br />

Hardware limit switch (from SW 2.0)<br />

27 traversing blocks (2 for jogging)<br />

Backlash compensation<br />

Set actual value<br />

Rotary axis with modulo correction<br />

Jerk limiting<br />

Standstill monitoring<br />

Traversing to fixed endstop<br />

Flying block change<br />

Standalone operation (from SW 1.2)<br />

Holding controller (from SW 1.3)<br />

Control sense can be reversed (from<br />

SW 1.3)<br />

Jogging without PROFIBUS and<br />

parameterization (from SW 1.4)<br />

Flying measurement/actual value<br />

setting (from SW 1.4)<br />

Speed setpoint interface<br />

(from SW 2.0)<br />

Load/electronics power supply<br />

Via a common cable<br />

Via a separate cable<br />

C1-C1 master ”SIMODRIVE<br />

POSMO A PROFIBUS MASTER”<br />

for PC/PG or notebook<br />

SimoCom A<br />

parameterizing and<br />

start–up tool<br />

(from SW 1.5)<br />

Communications via PROFIBUS DP<br />

PZD area<br />

(control words/status words)<br />

PKW area<br />

(read/write parameters)<br />

Modular gearbox system<br />

75 W motor<br />

Planetary/worm gear<br />

300 W motor:<br />

Planetary gear (can be<br />

interchanged)<br />

Siemens AG <strong>2003</strong> All rights reserved<br />

SIMODRIVE POSMO A <strong>User</strong> <strong>Manual</strong> (POS1) – <strong>08</strong>.03 <strong>Edition</strong>