- Page 1: Membrane and Desalination Technolog

- Page 4 and 5: Editors Dr. Lawrence K. Wang Zorex

- Page 6 and 7: vi Preface Our treatment of polluti

- Page 9 and 10: Contents Preface . ................

- Page 11 and 12: Contents xi 3.4. Considering Existi

- Page 13 and 14: Contents xiii 7. Membrane Separatio

- Page 15 and 16: Contents xv 6. Design for Large Com

- Page 17 and 18: Contents xvii 13. Desalination of S

- Page 19 and 20: Contributors JIRAPAT ANANPATTARACHA

- Page 21 and 22: CONTENTS 1 Membrane Technology: Pas

- Page 23 and 24: Membrane Technology: Past, Present

- Page 25 and 26: Membrane Technology: Past, Present

- Page 27 and 28: Membrane Technology: Past, Present

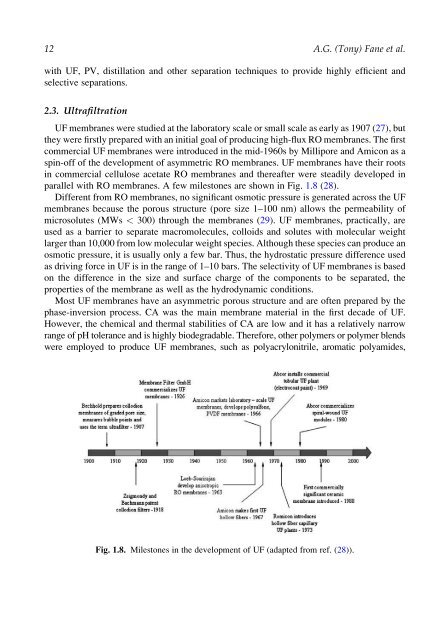

- Page 29 and 30: Membrane Technology: Past, Present

- Page 31: Membrane Technology: Past, Present

- Page 35 and 36: Membrane Technology: Past, Present

- Page 37 and 38: Membrane Technology: Past, Present

- Page 39 and 40: Membrane Technology: Past, Present

- Page 41 and 42: Membrane Technology: Past, Present

- Page 43 and 44: Membrane Technology: Past, Present

- Page 45 and 46: Membrane Technology: Past, Present

- Page 47 and 48: Membrane Technology: Past, Present

- Page 49 and 50: Membrane Technology: Past, Present

- Page 51 and 52: Membrane Technology: Past, Present

- Page 53 and 54: Membrane Technology: Past, Present

- Page 55 and 56: Membrane Technology: Past, Present

- Page 57 and 58: Membrane Technology: Past, Present

- Page 59 and 60: Membrane Technology: Past, Present

- Page 61 and 62: Membrane Technology: Past, Present

- Page 63 and 64: Membrane Technology: Past, Present

- Page 65 and 66: Membrane Technology: Past, Present

- Page 67 and 68: 48 J. Ren and R. Wang Key Words Pol

- Page 69 and 70: 50 J. Ren and R. Wang Nonporous den

- Page 71 and 72: 52 J. Ren and R. Wang pervaporation

- Page 73 and 74: 54 J. Ren and R. Wang HO HO OH O OH

- Page 75 and 76: 56 J. Ren and R. Wang Fig. 2.7 Chem

- Page 77 and 78: 58 J. Ren and R. Wang N O O 3.10. P

- Page 79 and 80: 60 J. Ren and R. Wang inversion, th

- Page 81 and 82: 62 J. Ren and R. Wang where Dm i an

- Page 83 and 84:

64 J. Ren and R. Wang as nucleation

- Page 85 and 86:

66 J. Ren and R. Wang and no polyme

- Page 87 and 88:

68 J. Ren and R. Wang where b ¼ v1

- Page 89 and 90:

70 J. Ren and R. Wang S gelation ti

- Page 91 and 92:

72 J. Ren and R. Wang structure wil

- Page 93 and 94:

74 J. Ren and R. Wang Viscous finge

- Page 95 and 96:

76 J. Ren and R. Wang nonsolvent so

- Page 97 and 98:

78 J. Ren and R. Wang Thickness of

- Page 99 and 100:

80 J. Ren and R. Wang 5.1.1. Rheolo

- Page 101 and 102:

82 J. Ren and R. Wang the spinneret

- Page 103 and 104:

84 J. Ren and R. Wang Dynamic visco

- Page 105 and 106:

86 J. Ren and R. Wang where A is th

- Page 107 and 108:

88 J. Ren and R. Wang In the spinni

- Page 109 and 110:

90 J. Ren and R. Wang stress, espec

- Page 111 and 112:

92 J. Ren and R. Wang solution at t

- Page 113 and 114:

94 J. Ren and R. Wang TIPS ¼ Therm

- Page 115 and 116:

96 J. Ren and R. Wang 5. Kesting RE

- Page 117 and 118:

98 J. Ren and R. Wang 51. Matsuyama

- Page 119 and 120:

100 J. Ren and R. Wang 92. Ren J, C

- Page 121 and 122:

102 L. Song and K.Guan Tay Key Word

- Page 123 and 124:

104 L. Song and K.Guan Tay Flux A A

- Page 125 and 126:

106 L. Song and K.Guan Tay increase

- Page 127 and 128:

108 L. Song and K.Guan Tay Table 3.

- Page 129 and 130:

110 L. Song and K.Guan Tay • A fe

- Page 131 and 132:

112 L. Song and K.Guan Tay Feed wat

- Page 133 and 134:

114 L. Song and K.Guan Tay Fouling

- Page 135 and 136:

116 L. Song and K.Guan Tay Fouling

- Page 137 and 138:

118 L. Song and K.Guan Tay The symb

- Page 139 and 140:

120 L. Song and K.Guan Tay Table 3.

- Page 141 and 142:

122 L. Song and K.Guan Tay Permeate

- Page 143 and 144:

124 L. Song and K.Guan Tay Average

- Page 145 and 146:

126 L. Song and K.Guan Tay Average

- Page 147 and 148:

128 L. Song and K.Guan Tay generati

- Page 149 and 150:

130 L. Song and K.Guan Tay Average

- Page 151 and 152:

132 L. Song and K.Guan Tay flux. Un

- Page 153 and 154:

134 L. Song and K.Guan Tay 14. Kaak

- Page 155 and 156:

136 N.K. Shammas and L.K. Wang remo

- Page 157 and 158:

138 N.K. Shammas and L.K. Wang The

- Page 159 and 160:

140 N.K. Shammas and L.K. Wang excu

- Page 161 and 162:

142 N.K. Shammas and L.K. Wang dire

- Page 163 and 164:

144 N.K. Shammas and L.K. Wang broa

- Page 165 and 166:

146 N.K. Shammas and L.K. Wang remo

- Page 167 and 168:

148 N.K. Shammas and L.K. Wang 4. T

- Page 169 and 170:

150 N.K. Shammas and L.K. Wang 8. S

- Page 171 and 172:

152 N.K. Shammas and L.K. Wang 4.5.

- Page 173 and 174:

154 N.K. Shammas and L.K. Wang Tabl

- Page 175 and 176:

156 N.K. Shammas and L.K. Wang phys

- Page 177 and 178:

158 N.K. Shammas and L.K. Wang mono

- Page 179 and 180:

160 N.K. Shammas and L.K. Wang 4.8.

- Page 181 and 182:

162 N.K. Shammas and L.K. Wang The

- Page 183 and 184:

164 N.K. Shammas and L.K. Wang Fig.

- Page 185 and 186:

166 N.K. Shammas and L.K. Wang Fig.

- Page 187 and 188:

168 N.K. Shammas and L.K. Wang Fig.

- Page 189 and 190:

170 N.K. Shammas and L.K. Wang CSTR

- Page 191 and 192:

172 N.K. Shammas and L.K. Wang chec

- Page 193 and 194:

174 N.K. Shammas and L.K. Wang due

- Page 195 and 196:

176 N.K. Shammas and L.K. Wang Tabl

- Page 197 and 198:

178 N.K. Shammas and L.K. Wang 4. C

- Page 199 and 200:

180 N.K. Shammas and L.K. Wang Tabl

- Page 201 and 202:

182 N.K. Shammas and L.K. Wang Sens

- Page 203 and 204:

184 N.K. Shammas and L.K. Wang Tabl

- Page 205 and 206:

186 N.K. Shammas and L.K. Wang Maxi

- Page 207 and 208:

188 N.K. Shammas and L.K. Wang 2. 2

- Page 209 and 210:

190 N.K. Shammas and L.K. Wang Tabl

- Page 211 and 212:

192 N.K. Shammas and L.K. Wang Tabl

- Page 213 and 214:

194 N.K. Shammas and L.K. Wang Fig.

- Page 215 and 216:

196 N.K. Shammas and L.K. Wang PFR

- Page 217 and 218:

198 N.K. Shammas and L.K. Wang 16.

- Page 219 and 220:

5 Treatment of Industrial Effluents

- Page 221 and 222:

Treatment of Industrial Effluents,

- Page 223 and 224:

Treatment of Industrial Effluents,

- Page 225 and 226:

Treatment of Industrial Effluents,

- Page 227 and 228:

Treatment of Industrial Effluents,

- Page 229 and 230:

Treatment of Industrial Effluents,

- Page 231 and 232:

Treatment of Industrial Effluents,

- Page 233 and 234:

Treatment of Industrial Effluents,

- Page 235 and 236:

Treatment of Industrial Effluents,

- Page 237 and 238:

Treatment of Industrial Effluents,

- Page 239 and 240:

Treatment of Industrial Effluents,

- Page 241 and 242:

Treatment of Industrial Effluents,

- Page 243 and 244:

Treatment of Industrial Effluents,

- Page 245 and 246:

Treatment of Industrial Effluents,

- Page 247 and 248:

Treatment of Industrial Effluents,

- Page 249 and 250:

Treatment of Industrial Effluents,

- Page 251 and 252:

Treatment of Industrial Effluents,

- Page 253 and 254:

Treatment of Industrial Effluents,

- Page 255 and 256:

CONTENTS 6 Treatment of Food Indust

- Page 257 and 258:

Treatment of Food Industry Foods an

- Page 259 and 260:

Treatment of Food Industry Foods an

- Page 261 and 262:

Treatment of Food Industry Foods an

- Page 263 and 264:

Treatment of Food Industry Foods an

- Page 265 and 266:

Treatment of Food Industry Foods an

- Page 267 and 268:

Treatment of Food Industry Foods an

- Page 269 and 270:

Treatment of Food Industry Foods an

- Page 271 and 272:

Treatment of Food Industry Foods an

- Page 273 and 274:

Treatment of Food Industry Foods an

- Page 275 and 276:

Treatment of Food Industry Foods an

- Page 277 and 278:

Treatment of Food Industry Foods an

- Page 279 and 280:

Treatment of Food Industry Foods an

- Page 281 and 282:

Treatment of Food Industry Foods an

- Page 283 and 284:

Treatment of Food Industry Foods an

- Page 285 and 286:

Treatment of Food Industry Foods an

- Page 287 and 288:

Treatment of Food Industry Foods an

- Page 289 and 290:

272 J. Paul Chen et al. formation a

- Page 291 and 292:

274 J. Paul Chen et al. the rejecte

- Page 293 and 294:

276 J. Paul Chen et al. The MF memb

- Page 295 and 296:

278 J. Paul Chen et al. Most UF mem

- Page 297 and 298:

280 J. Paul Chen et al. The applica

- Page 299 and 300:

282 J. Paul Chen et al. solutions a

- Page 301 and 302:

284 J. Paul Chen et al. Salt cheese

- Page 303 and 304:

286 J. Paul Chen et al. Table 7.2 L

- Page 305 and 306:

288 J. Paul Chen et al. Table 7.3 L

- Page 307 and 308:

290 J. Paul Chen et al. Fig. 7.7. V

- Page 309 and 310:

292 J. Paul Chen et al. Considering

- Page 311 and 312:

294 J. Paul Chen et al. Approximati

- Page 313 and 314:

296 J. Paul Chen et al. 5.2. The Po

- Page 315 and 316:

298 J. Paul Chen et al. into a smal

- Page 317 and 318:

300 J. Paul Chen et al. 6.2.3. Tubu

- Page 319 and 320:

302 J. Paul Chen et al. Fig. 7.13.

- Page 321 and 322:

304 J. Paul Chen et al. a Feed b Me

- Page 323 and 324:

306 J. Paul Chen et al. l Product c

- Page 325 and 326:

308 J. Paul Chen et al. Feed Permea

- Page 327 and 328:

310 J. Paul Chen et al. From Table

- Page 329 and 330:

312 J. Paul Chen et al. To calculat

- Page 331 and 332:

314 J. Paul Chen et al. biofilm for

- Page 333 and 334:

316 J. Paul Chen et al. magnesium,

- Page 335 and 336:

318 J. Paul Chen et al. reduction o

- Page 337 and 338:

320 J. Paul Chen et al. Table 7.6 C

- Page 339 and 340:

322 J. Paul Chen et al. many factor

- Page 341 and 342:

324 J. Paul Chen et al. 9.2. Gas Se

- Page 343 and 344:

326 J. Paul Chen et al. c w2 ¼ Con

- Page 345 and 346:

328 J. Paul Chen et al. 14. Economi

- Page 347 and 348:

330 J. Paul Chen et al. 55. Basu OD

- Page 349 and 350:

332 J. Paul Chen et al. 99. Teodosi

- Page 351 and 352:

334 N.K. Shammas and L.K. Wang 1. I

- Page 353 and 354:

336 N.K. Shammas and L.K. Wang dete

- Page 355 and 356:

338 N.K. Shammas and L.K. Wang for

- Page 357 and 358:

340 N.K. Shammas and L.K. Wang Tabl

- Page 359 and 360:

342 N.K. Shammas and L.K. Wang impo

- Page 361 and 362:

344 N.K. Shammas and L.K. Wang Fig.

- Page 363 and 364:

346 N.K. Shammas and L.K. Wang prio

- Page 365 and 366:

348 N.K. Shammas and L.K. Wang 5-20

- Page 367 and 368:

350 N.K. Shammas and L.K. Wang 3.2.

- Page 369 and 370:

352 N.K. Shammas and L.K. Wang Tabl

- Page 371 and 372:

354 N.K. Shammas and L.K. Wang cour

- Page 373 and 374:

356 N.K. Shammas and L.K. Wang The

- Page 375 and 376:

358 N.K. Shammas and L.K. Wang wher

- Page 377 and 378:

360 N.K. Shammas and L.K. Wang and

- Page 379 and 380:

362 N.K. Shammas and L.K. Wang syst

- Page 381 and 382:

364 N.K. Shammas and L.K. Wang blee

- Page 383 and 384:

366 N.K. Shammas and L.K. Wang Tabl

- Page 385 and 386:

368 N.K. Shammas and L.K. Wang Tabl

- Page 387 and 388:

370 N.K. Shammas and L.K. Wang oxid

- Page 389 and 390:

372 N.K. Shammas and L.K. Wang memb

- Page 391 and 392:

374 N.K. Shammas and L.K. Wang Fig.

- Page 393 and 394:

376 N.K. Shammas and L.K. Wang capa

- Page 395 and 396:

378 N.K. Shammas and L.K. Wang Disp

- Page 397 and 398:

380 N.K. Shammas and L.K. Wang sali

- Page 399 and 400:

382 N.K. Shammas and L.K. Wang 7.3.

- Page 401 and 402:

384 N.K. Shammas and L.K. Wang the

- Page 403 and 404:

386 N.K. Shammas and L.K. Wang 9. N

- Page 405 and 406:

388 N.K. Shammas and L.K. Wang 16.

- Page 407 and 408:

CONTENTS 9 Adsorption Desalination:

- Page 409 and 410:

Adsorption Desalination: A Novel Me

- Page 411 and 412:

Adsorption Desalination: A Novel Me

- Page 413 and 414:

Adsorption Desalination: A Novel Me

- Page 415 and 416:

Adsorption Desalination: A Novel Me

- Page 417 and 418:

Adsorption Desalination: A Novel Me

- Page 419 and 420:

Adsorption Desalination: A Novel Me

- Page 421 and 422:

Adsorption Desalination: A Novel Me

- Page 423 and 424:

Adsorption Desalination: A Novel Me

- Page 425 and 426:

Adsorption Desalination: A Novel Me

- Page 427 and 428:

Adsorption Desalination: A Novel Me

- Page 429 and 430:

Adsorption Desalination: A Novel Me

- Page 431 and 432:

Adsorption Desalination: A Novel Me

- Page 433 and 434:

Adsorption Desalination: A Novel Me

- Page 435 and 436:

Adsorption Desalination: A Novel Me

- Page 437 and 438:

Adsorption Desalination: A Novel Me

- Page 439 and 440:

Adsorption Desalination: A Novel Me

- Page 441 and 442:

Adsorption Desalination: A Novel Me

- Page 443 and 444:

Adsorption Desalination: A Novel Me

- Page 445 and 446:

Adsorption Desalination: A Novel Me

- Page 447 and 448:

Adsorption Desalination: A Novel Me

- Page 449 and 450:

434 J. Qin and K.A. Kekre 1. INTROD

- Page 451 and 452:

436 J. Qin and K.A. Kekre utilized

- Page 453 and 454:

438 J. Qin and K.A. Kekre 3.2. Desc

- Page 455 and 456:

440 J. Qin and K.A. Kekre Table 10.

- Page 457 and 458:

442 J. Qin and K.A. Kekre Fig. 10.4

- Page 459 and 460:

444 J. Qin and K.A. Kekre Fig. 10.5

- Page 461 and 462:

446 J. Qin and K.A. Kekre different

- Page 463 and 464:

448 J. Qin and K.A. Kekre protectin

- Page 465 and 466:

450 J. Qin and K.A. Kekre Table 10.

- Page 467 and 468:

452 J. Qin and K.A. Kekre Fig. 10.8

- Page 469 and 470:

454 J. Qin and K.A. Kekre Fig. 10.1

- Page 471 and 472:

456 J. Qin and K.A. Kekre Table 10.

- Page 473 and 474:

458 J. Qin and K.A. Kekre Table 10.

- Page 475 and 476:

460 J. Qin and K.A. Kekre Fig. 10.1

- Page 477 and 478:

462 J. Qin and K.A. Kekre 7.2. Desc

- Page 479 and 480:

464 J. Qin and K.A. Kekre Table 10.

- Page 481 and 482:

466 J. Qin and K.A. Kekre Fig. 10.1

- Page 483 and 484:

468 J. Qin and K.A. Kekre and anion

- Page 485 and 486:

470 J. Qin and K.A. Kekre become on

- Page 487 and 488:

472 J. Qin and K.A. Kekre COD ¼ Ch

- Page 489 and 490:

474 J. Qin and K.A. Kekre 25. Parso

- Page 491 and 492:

476 J. Qin and K.A. Kekre technique

- Page 493 and 494:

478 P. Kajitvichyanukul et al. 1. I

- Page 495 and 496:

480 P. Kajitvichyanukul et al. of 5

- Page 497 and 498:

482 P. Kajitvichyanukul et al. well

- Page 499 and 500:

484 P. Kajitvichyanukul et al. The

- Page 501 and 502:

486 P. Kajitvichyanukul et al. 3.3.

- Page 503 and 504:

488 P. Kajitvichyanukul et al. 4. C

- Page 505 and 506:

490 P. Kajitvichyanukul et al. nonp

- Page 507 and 508:

492 P. Kajitvichyanukul et al. rDNA

- Page 509 and 510:

494 P. Kajitvichyanukul et al. 3. E

- Page 511 and 512:

496 P. Kajitvichyanukul et al. Form

- Page 513 and 514:

498 P. Kajitvichyanukul et al. 4.4.

- Page 515 and 516:

500 P. Kajitvichyanukul et al. do n

- Page 517 and 518:

502 P. Kajitvichyanukul et al. Wate

- Page 519 and 520:

504 P. Kajitvichyanukul et al. Tabl

- Page 521 and 522:

506 P. Kajitvichyanukul et al. Fig.

- Page 523 and 524:

508 P. Kajitvichyanukul et al. Tabl

- Page 525 and 526:

510 P. Kajitvichyanukul et al. Fig.

- Page 527 and 528:

512 P. Kajitvichyanukul et al. solu

- Page 529 and 530:

514 P. Kajitvichyanukul et al. 5.6.

- Page 531 and 532:

516 P. Kajitvichyanukul et al. (b)

- Page 533 and 534:

518 P. Kajitvichyanukul et al. 8. A

- Page 535 and 536:

520 P. Kajitvichyanukul et al. 52.

- Page 537 and 538:

522 P. Kajitvichyanukul et al. 94.

- Page 539 and 540:

12 Desalination of Seawater by Ther

- Page 541 and 542:

Desalination of Seawater by Thermal

- Page 543 and 544:

Desalination of Seawater by Thermal

- Page 545 and 546:

Desalination of Seawater by Thermal

- Page 547 and 548:

Desalination of Seawater by Thermal

- Page 549 and 550:

Desalination of Seawater by Thermal

- Page 551 and 552:

Desalination of Seawater by Thermal

- Page 553 and 554:

Desalination of Seawater by Thermal

- Page 555 and 556:

Desalination of Seawater by Thermal

- Page 557 and 558:

Desalination of Seawater by Thermal

- Page 559 and 560:

Desalination of Seawater by Thermal

- Page 561 and 562:

Desalination of Seawater by Thermal

- Page 563 and 564:

Desalination of Seawater by Thermal

- Page 565 and 566:

Desalination of Seawater by Thermal

- Page 567 and 568:

Desalination of Seawater by Thermal

- Page 569 and 570:

Desalination of Seawater by Thermal

- Page 571 and 572:

Desalination of Seawater by Thermal

- Page 573 and 574:

CONTENTS 13 Desalination of Seawate

- Page 575 and 576:

Desalination of Seawater by Reverse

- Page 577 and 578:

Desalination of Seawater by Reverse

- Page 579 and 580:

Desalination of Seawater by Reverse

- Page 581 and 582:

Desalination of Seawater by Reverse

- Page 583 and 584:

Desalination of Seawater by Reverse

- Page 585 and 586:

Desalination of Seawater by Reverse

- Page 587 and 588:

Desalination of Seawater by Reverse

- Page 589 and 590:

Desalination of Seawater by Reverse

- Page 591 and 592:

Desalination of Seawater by Reverse

- Page 593 and 594:

Desalination of Seawater by Reverse

- Page 595 and 596:

Desalination of Seawater by Reverse

- Page 597 and 598:

Desalination of Seawater by Reverse

- Page 599 and 600:

Desalination of Seawater by Reverse

- Page 601 and 602:

Desalination of Seawater by Reverse

- Page 603 and 604:

Desalination of Seawater by Reverse

- Page 605 and 606:

Desalination of Seawater by Reverse

- Page 607 and 608:

Desalination of Seawater by Reverse

- Page 609 and 610:

Desalination of Seawater by Reverse

- Page 611 and 612:

Desalination of Seawater by Reverse

- Page 613 and 614:

Desalination of Seawater by Reverse

- Page 615 and 616:

Desalination of Seawater by Reverse

- Page 617 and 618:

604 P. Kajitvichyanukul et al. wate

- Page 619 and 620:

606 P. Kajitvichyanukul et al. hydr

- Page 621 and 622:

608 P. Kajitvichyanukul et al. it i

- Page 623 and 624:

610 P. Kajitvichyanukul et al. UV i

- Page 625 and 626:

612 P. Kajitvichyanukul et al. The

- Page 627 and 628:

614 P. Kajitvichyanukul et al. abov

- Page 629 and 630:

616 P. Kajitvichyanukul et al. Fig.

- Page 631 and 632:

618 P. Kajitvichyanukul et al. larg

- Page 633 and 634:

620 P. Kajitvichyanukul et al. insi

- Page 635 and 636:

622 P. Kajitvichyanukul et al. acti

- Page 637 and 638:

624 P. Kajitvichyanukul et al. wate

- Page 639 and 640:

626 P. Kajitvichyanukul et al. affe

- Page 641 and 642:

628 P. Kajitvichyanukul et al. Adju

- Page 643 and 644:

630 P. Kajitvichyanukul et al. 4. D

- Page 645 and 646:

632 P. Kajitvichyanukul et al. For

- Page 647 and 648:

634 P. Kajitvichyanukul et al. Cc

- Page 649 and 650:

636 P. Kajitvichyanukul et al. 22.

- Page 651 and 652:

638 P. Kajitvichyanukul et al. 63.

- Page 653 and 654:

640 P. Kajitvichyanukul et al. grea

- Page 655 and 656:

642 P. Kajitvichyanukul et al. 2. F

- Page 657 and 658:

644 P. Kajitvichyanukul et al. cond

- Page 659 and 660:

646 P. Kajitvichyanukul et al. foll

- Page 661 and 662:

648 P. Kajitvichyanukul et al. l En

- Page 663 and 664:

650 P. Kajitvichyanukul et al. oil-

- Page 665 and 666:

652 P. Kajitvichyanukul et al. Feed

- Page 667 and 668:

654 P. Kajitvichyanukul et al. O 2

- Page 669 and 670:

656 P. Kajitvichyanukul et al. prea

- Page 671 and 672:

658 P. Kajitvichyanukul et al. holl

- Page 673 and 674:

660 P. Kajitvichyanukul et al. wher

- Page 675 and 676:

662 P. Kajitvichyanukul et al. 10 L

- Page 677 and 678:

664 P. Kajitvichyanukul et al. 16.

- Page 679 and 680:

666 P. Kajitvichyanukul et al. 59.

- Page 681 and 682:

668 P. Kajitvichyanukul et al. 98.

- Page 683 and 684:

670 K. Mohanty and R. Ghosh 1. INTR

- Page 685 and 686:

672 K. Mohanty and R. Ghosh municip

- Page 687 and 688:

674 K. Mohanty and R. Ghosh 3.2. Tw

- Page 689 and 690:

676 K. Mohanty and R. Ghosh Fig. 16

- Page 691 and 692:

678 K. Mohanty and R. Ghosh Fig. 16

- Page 693 and 694:

680 K. Mohanty and R. Ghosh Cabassu

- Page 695 and 696:

682 K. Mohanty and R. Ghosh 4.3. Ga

- Page 697 and 698:

684 K. Mohanty and R. Ghosh Membran

- Page 699 and 700:

686 K. Mohanty and R. Ghosh Fig. 16

- Page 701 and 702:

688 K. Mohanty and R. Ghosh MBRs ca

- Page 703 and 704:

690 K. Mohanty and R. Ghosh two pro

- Page 705 and 706:

692 K. Mohanty and R. Ghosh can be

- Page 707 and 708:

694 K. Mohanty and R. Ghosh 27. Bel

- Page 709 and 710:

696 K. Mohanty and R. Ghosh 70. Fut

- Page 711 and 712:

Acceptance testing, 384-385 ACF. Se

- Page 713 and 714:

Index 701 Challenge test solution d

- Page 715 and 716:

Index 703 Disinfection by-products

- Page 717 and 718:

Index 705 Hemodialysis, 2, 6, 281 H

- Page 719 and 720:

Index 707 Membrane bioreactor-rever

- Page 721 and 722:

Index 709 Microfiltration-reverse o

- Page 723 and 724:

Index 711 Physical cleaning, 322-32

- Page 725 and 726:

Index 713 Reynolds number, 676, 679

- Page 727 and 728:

Index 715 Thermal concentration, 25