to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

The most common system being promoted for <strong>the</strong> treatment of MSW using MHT is based around a<br />

<strong>the</strong>rmal au<strong>to</strong>clave. The development for use with MSW started in <strong>the</strong> early 1990’s, and a number of<br />

patents have been issued.<br />

A second type of MHT system is a non-pressurised heat treatment process, where waste is mixed <strong>to</strong> a<br />

slurry with water and <strong>the</strong>n heated in a rotating kiln prior <strong>to</strong> mechanical separation. This process requires<br />

a pre-treatment stage, which includes <strong>the</strong> use of a shredder.<br />

Both <strong>the</strong> au<strong>to</strong>clave process and <strong>the</strong> non-pressurised treatment processes have <strong>the</strong> following effect on <strong>the</strong><br />

waste:<br />

• Biodegradable materials, including paper and card, are broken down in<strong>to</strong> a high biomass fibre for<br />

which <strong>the</strong> main use is as a fuel product;<br />

• Glass bottles and tins have <strong>the</strong>ir labels removed as <strong>the</strong> glue disintegrates under <strong>the</strong> action of <strong>the</strong><br />

heat;<br />

• Plastics are softened, and labels are removed. Certain types of plastics are deformed <strong>by</strong> <strong>the</strong> heat,<br />

but remain in a recognisable state, whereas o<strong>the</strong>r plastics soften completely forming hard balls of<br />

dense plastic.<br />

Both processes produce product streams (fibre product, plastic, etc) using well-established mechanical<br />

processing techniques (screening, density separation, magnetic separation, eddy current separation).<br />

The resulting outputs are relatively clean ‘hard’ recyclables (tins, glass and plastics with no labels and<br />

most of <strong>the</strong> food waste removed) a fibrous material from <strong>the</strong> breakdown of paper, card and green/kitchen<br />

waste constituents, and a reject fraction.<br />

Both systems heat <strong>the</strong> waste <strong>to</strong> temperatures in <strong>the</strong> range of 120-170°C, which is sufficient <strong>to</strong> destroy<br />

bacteria present in <strong>the</strong> waste. This has benefits in terms of s<strong>to</strong>rage, transport and handling of <strong>the</strong> outputs<br />

as <strong>the</strong>y are sanitised, and are free from <strong>the</strong> biological activity that may give rise <strong>to</strong> odour problems. There<br />

is also a significant volume reduction in <strong>the</strong> waste.<br />

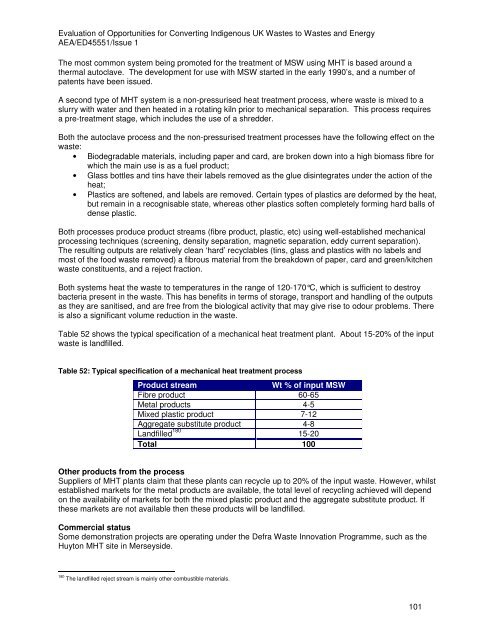

Table 52 shows <strong>the</strong> typical specification of a mechanical heat treatment plant. About 15-20% of <strong>the</strong> input<br />

waste is landfilled.<br />

Table 52: Typical specification of a mechanical heat treatment process<br />

Product stream Wt % of input MSW<br />

Fibre product 60-65<br />

Metal products 4-5<br />

Mixed plastic product 7-12<br />

Aggregate substitute product 4-8<br />

Landfilled 180 15-20<br />

Total 100<br />

O<strong>the</strong>r products from <strong>the</strong> process<br />

Suppliers of MHT plants claim that <strong>the</strong>se plants can recycle up <strong>to</strong> 20% of <strong>the</strong> input waste. However, whilst<br />

established markets for <strong>the</strong> metal products are available, <strong>the</strong> <strong>to</strong>tal level of recycling achieved will depend<br />

on <strong>the</strong> availability of markets for both <strong>the</strong> mixed plastic product and <strong>the</strong> aggregate substitute product. If<br />

<strong>the</strong>se markets are not available <strong>the</strong>n <strong>the</strong>se products will be landfilled.<br />

Commercial status<br />

Some demonstration projects are operating under <strong>the</strong> Defra Waste Innovation Programme, such as <strong>the</strong><br />

Huy<strong>to</strong>n MHT site in Merseyside.<br />

180 The landfilled reject stream is mainly o<strong>the</strong>r combustible materials.<br />

101