to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

80<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

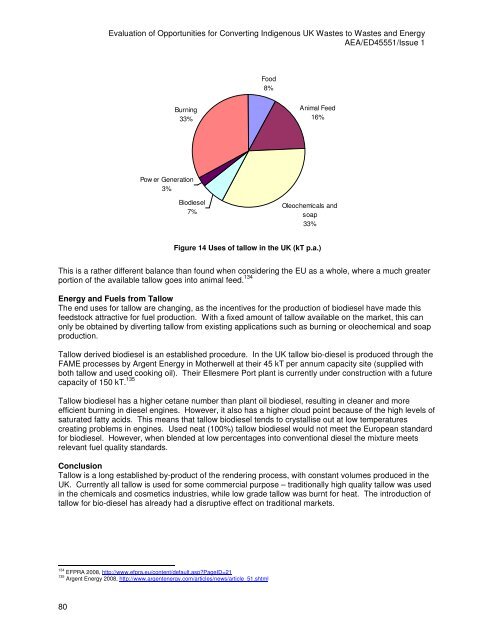

Burning<br />

33%<br />

Pow er Generation<br />

3%<br />

Biodiesel<br />

7%<br />

Food<br />

8%<br />

Animal Feed<br />

16%<br />

Oleochemicals and<br />

soap<br />

33%<br />

Figure 14 Uses of tallow in <strong>the</strong> UK (kT p.a.)<br />

This is a ra<strong>the</strong>r different balance than found when considering <strong>the</strong> EU as a whole, where a much greater<br />

portion of <strong>the</strong> available tallow goes in<strong>to</strong> animal feed. 134<br />

Energy and Fuels from Tallow<br />

The end uses for tallow are changing, as <strong>the</strong> incentives for <strong>the</strong> production of biodiesel have made this<br />

feeds<strong>to</strong>ck attractive for fuel production. With a fixed amount of tallow available on <strong>the</strong> market, this can<br />

only be obtained <strong>by</strong> diverting tallow from existing applications such as burning or oleochemical and soap<br />

production.<br />

Tallow derived biodiesel is an established procedure. In <strong>the</strong> UK tallow bio-diesel is produced through <strong>the</strong><br />

FAME processes <strong>by</strong> Argent Energy in Mo<strong>the</strong>rwell at <strong>the</strong>ir 45 kT per annum capacity site (supplied with<br />

both tallow and used cooking oil). Their Ellesmere Port plant is currently under construction with a future<br />

capacity of 150 kT. 135<br />

Tallow biodiesel has a higher cetane number than plant oil biodiesel, resulting in cleaner and more<br />

efficient burning in diesel engines. However, it also has a higher cloud point because of <strong>the</strong> high levels of<br />

saturated fatty acids. This means that tallow biodiesel tends <strong>to</strong> crystallise out at low temperatures<br />

creating problems in engines. Used neat (100%) tallow biodiesel would not meet <strong>the</strong> European standard<br />

for biodiesel. However, when blended at low percentages in<strong>to</strong> conventional diesel <strong>the</strong> mixture meets<br />

relevant fuel quality standards.<br />

Conclusion<br />

Tallow is a long established <strong>by</strong>-product of <strong>the</strong> rendering process, with constant volumes produced in <strong>the</strong><br />

UK. Currently all tallow is used for some commercial purpose – traditionally high quality tallow was used<br />

in <strong>the</strong> chemicals and cosmetics industries, while low grade tallow was burnt for heat. The introduction of<br />

tallow for bio-diesel has al<strong>read</strong>y had a disruptive effect on traditional markets.<br />

134 EFPRA 2008, http://www.efpra.eu/content/default.asp?PageID=21<br />

135 Argent Energy 2008, http://www.argentenergy.com/articles/news/article_51.shtml