to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Fuels and Energy<br />

AEA/ED45551/Issue 1<br />

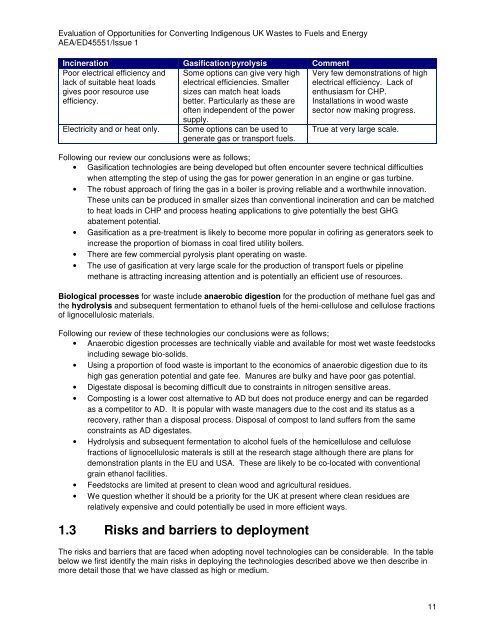

Incineration Gasification/pyrolysis Comment<br />

Poor electrical efficiency and<br />

lack of suitable heat loads<br />

gives poor resource use<br />

efficiency.<br />

Some options can give very high<br />

electrical efficiencies. Smaller<br />

sizes can match heat loads<br />

better. Particularly as <strong>the</strong>se are<br />

often independent of <strong>the</strong> power<br />

supply.<br />

Electricity and or heat only. Some options can be used <strong>to</strong><br />

generate gas or transport fuels.<br />

Very few demonstrations of high<br />

electrical efficiency. Lack of<br />

enthusiasm for CHP.<br />

Installations in wood waste<br />

sec<strong>to</strong>r now making progress.<br />

True at very large scale.<br />

Following our review our conclusions were as follows;<br />

• Gasification technologies are being developed but often encounter severe technical difficulties<br />

when attempting <strong>the</strong> step of using <strong>the</strong> gas for power generation in an engine or gas turbine.<br />

• The robust approach of firing <strong>the</strong> gas in a boiler is proving reliable and a worthwhile innovation.<br />

These units can be produced in smaller sizes than conventional incineration and can be matched<br />

<strong>to</strong> heat loads in CHP and process heating applications <strong>to</strong> give potentially <strong>the</strong> best GHG<br />

abatement potential.<br />

• Gasification as a pre-treatment is likely <strong>to</strong> become more popular in cofiring as genera<strong>to</strong>rs seek <strong>to</strong><br />

increase <strong>the</strong> proportion of biomass in coal fired utility boilers.<br />

• There are few commercial pyrolysis plant operating on waste.<br />

• The use of gasification at very large scale for <strong>the</strong> production of transport fuels or pipeline<br />

methane is attracting increasing attention and is potentially an efficient use of resources.<br />

Biological processes for waste include anaerobic digestion for <strong>the</strong> production of methane fuel gas and<br />

<strong>the</strong> hydrolysis and subsequent fermentation <strong>to</strong> ethanol fuels of <strong>the</strong> hemi-cellulose and cellulose fractions<br />

of lignocellulosic materials.<br />

Following our review of <strong>the</strong>se technologies our conclusions were as follows;<br />

• Anaerobic digestion processes are technically viable and available for most wet waste feeds<strong>to</strong>cks<br />

including sewage bio-solids.<br />

• Using a proportion of food waste is important <strong>to</strong> <strong>the</strong> economics of anaerobic digestion due <strong>to</strong> its<br />

high gas generation potential and gate fee. Manures are bulky and have poor gas potential.<br />

• Digestate disposal is becoming difficult due <strong>to</strong> constraints in nitrogen sensitive areas.<br />

• Composting is a lower cost alternative <strong>to</strong> AD but does not produce energy and can be regarded<br />

as a competi<strong>to</strong>r <strong>to</strong> AD. It is popular with waste managers due <strong>to</strong> <strong>the</strong> cost and its status as a<br />

recovery, ra<strong>the</strong>r than a disposal process. Disposal of compost <strong>to</strong> land suffers from <strong>the</strong> same<br />

constraints as AD digestates.<br />

• Hydrolysis and subsequent fermentation <strong>to</strong> alcohol fuels of <strong>the</strong> hemicellulose and cellulose<br />

fractions of lignocellulosic materals is still at <strong>the</strong> research stage although <strong>the</strong>re are plans for<br />

demonstration plants in <strong>the</strong> EU and USA. These are likely <strong>to</strong> be co-located with conventional<br />

grain ethanol facilities.<br />

• Feeds<strong>to</strong>cks are limited at present <strong>to</strong> clean wood and agricultural residues.<br />

• We question whe<strong>the</strong>r it should be a priority for <strong>the</strong> UK at present where clean residues are<br />

relatively expensive and could potentially be used in more efficient ways.<br />

1.3 Risks and barriers <strong>to</strong> deployment<br />

The risks and barriers that are faced when adopting novel technologies can be considerable. In <strong>the</strong> table<br />

below we first identify <strong>the</strong> main risks in deploying <strong>the</strong> technologies described above we <strong>the</strong>n describe in<br />

more detail those that we have classed as high or medium.<br />

11