to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

118<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

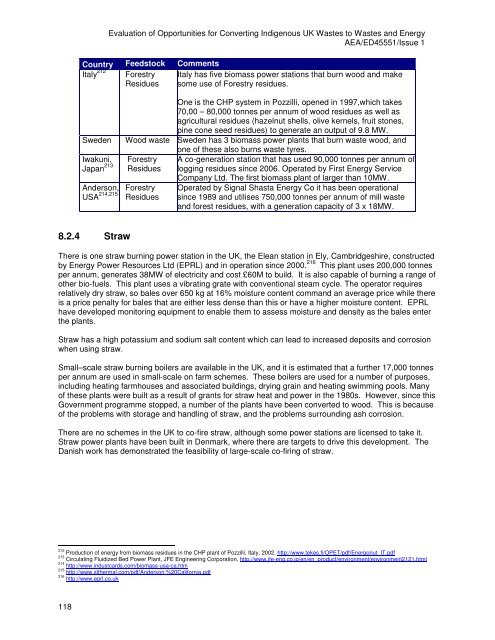

Country Feeds<strong>to</strong>ck Comments<br />

Italy 212 Forestry<br />

Residues<br />

Italy has five biomass power stations that burn wood and make<br />

some use of Forestry residues.<br />

One is <strong>the</strong> CHP system in Pozzilli, opened in 1997,which takes<br />

70,00 – 80,000 <strong>to</strong>nnes per annum of wood residues as well as<br />

agricultural residues (hazelnut shells, olive kernels, fruit s<strong>to</strong>nes,<br />

pine cone seed residues) <strong>to</strong> generate an output of 9.8 MW.<br />

Sweden Wood waste Sweden has 3 biomass power plants that burn waste wood, and<br />

Iwakuni,<br />

Japan 213<br />

Anderson,<br />

USA 214,215<br />

8.2.4 Straw<br />

Forestry<br />

Residues<br />

Forestry<br />

Residues<br />

one of <strong>the</strong>se also burns waste tyres.<br />

A co-generation station that has used 90,000 <strong>to</strong>nnes per annum of<br />

logging residues since 2006. Operated <strong>by</strong> First Energy Service<br />

Company Ltd. The first biomass plant of larger than 10MW.<br />

Operated <strong>by</strong> Signal Shasta Energy Co it has been operational<br />

since 1989 and utilises 750,000 <strong>to</strong>nnes per annum of mill waste<br />

and forest residues, with a generation capacity of 3 x 18MW.<br />

There is one straw burning power station in <strong>the</strong> UK, <strong>the</strong> Elean station in Ely, Cambridgeshire, constructed<br />

<strong>by</strong> Energy Power Resources Ltd (EPRL) and in operation since 2000. 216 This plant uses 200,000 <strong>to</strong>nnes<br />

per annum, generates 38MW of electricity and cost £60M <strong>to</strong> build. It is also capable of burning a range of<br />

o<strong>the</strong>r bio-fuels. This plant uses a vibrating grate with conventional steam cycle. The opera<strong>to</strong>r requires<br />

relatively dry straw, so bales over 650 kg at 16% moisture content command an average price while <strong>the</strong>re<br />

is a price penalty for bales that are ei<strong>the</strong>r less dense than this or have a higher moisture content. EPRL<br />

have developed moni<strong>to</strong>ring equipment <strong>to</strong> enable <strong>the</strong>m <strong>to</strong> assess moisture and density as <strong>the</strong> bales enter<br />

<strong>the</strong> plants.<br />

Straw has a high potassium and sodium salt content which can lead <strong>to</strong> increased deposits and corrosion<br />

when using straw.<br />

Small–scale straw burning boilers are available in <strong>the</strong> UK, and it is estimated that a fur<strong>the</strong>r 17,000 <strong>to</strong>nnes<br />

per annum are used in small-scale on farm schemes. These boilers are used for a number of purposes,<br />

including heating farmhouses and associated buildings, drying grain and heating swimming pools. Many<br />

of <strong>the</strong>se plants were built as a result of grants for straw heat and power in <strong>the</strong> 1980s. However, since this<br />

Government programme s<strong>to</strong>pped, a number of <strong>the</strong> plants have been converted <strong>to</strong> wood. This is because<br />

of <strong>the</strong> problems with s<strong>to</strong>rage and handling of straw, and <strong>the</strong> problems surrounding ash corrosion.<br />

There are no schemes in <strong>the</strong> UK <strong>to</strong> co-fire straw, although some power stations are licensed <strong>to</strong> take it.<br />

Straw power plants have been built in Denmark, where <strong>the</strong>re are targets <strong>to</strong> drive this development. The<br />

Danish work has demonstrated <strong>the</strong> feasibility of large-scale co-firing of straw.<br />

212 Production of energy from biomass residues in <strong>the</strong> CHP plant of Pozzilli, Italy, 2002, http://www.tekes.fi/OPET/pdf/Energonut_IT.pdf<br />

213 Circulating Fluidized Bed Power Plant, JFE Engineering Corporation, http://www.jfe-eng.co.jp/en/en_product/environment/environment2121.html<br />

214 http://www.industcards.com/biomass-usa-ca.htm<br />

215 http://www.sl<strong>the</strong>rmal.com/pdf/Anderson,%20California.pdf<br />

216 http://www.eprl.co.uk