to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

106<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

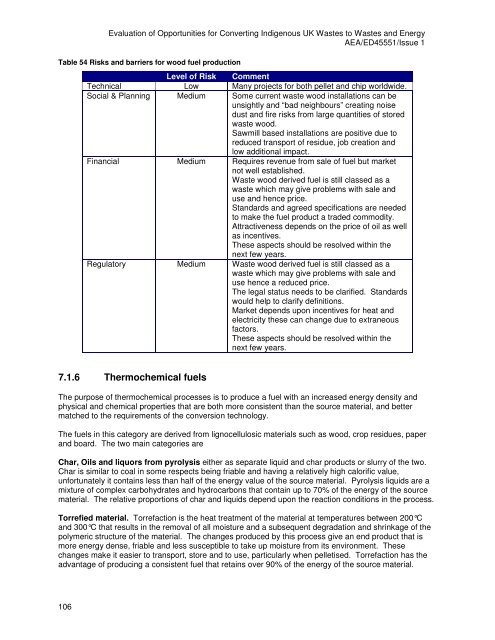

Table 54 Risks and barriers for wood fuel production<br />

Level of Risk Comment<br />

Technical Low Many projects for both pellet and chip worldwide.<br />

Social & Planning Medium Some current waste wood installations can be<br />

unsightly and “bad neighbours” creating noise<br />

dust and fire risks from large quantities of s<strong>to</strong>red<br />

waste wood.<br />

Sawmill based installations are positive due <strong>to</strong><br />

reduced transport of residue, job creation and<br />

low additional impact.<br />

Financial Medium Requires revenue from sale of fuel but market<br />

not well established.<br />

Waste wood derived fuel is still classed as a<br />

waste which may give problems with sale and<br />

use and hence price.<br />

Standards and agreed specifications are needed<br />

<strong>to</strong> make <strong>the</strong> fuel product a traded commodity.<br />

Attractiveness depends on <strong>the</strong> price of oil as well<br />

as incentives.<br />

These aspects should be resolved within <strong>the</strong><br />

next few years.<br />

Regula<strong>to</strong>ry Medium Waste wood derived fuel is still classed as a<br />

waste which may give problems with sale and<br />

use hence a reduced price.<br />

The legal status needs <strong>to</strong> be clarified. Standards<br />

would help <strong>to</strong> clarify definitions.<br />

Market depends upon incentives for heat and<br />

electricity <strong>the</strong>se can change due <strong>to</strong> extraneous<br />

fac<strong>to</strong>rs.<br />

These aspects should be resolved within <strong>the</strong><br />

next few years.<br />

7.1.6 Thermochemical fuels<br />

The purpose of <strong>the</strong>rmochemical processes is <strong>to</strong> produce a fuel with an increased energy density and<br />

physical and chemical properties that are both more consistent than <strong>the</strong> source material, and better<br />

matched <strong>to</strong> <strong>the</strong> requirements of <strong>the</strong> conversion technology.<br />

The fuels in this category are derived from lignocellulosic materials such as wood, crop residues, paper<br />

and board. The two main categories are<br />

Char, Oils and liquors from pyrolysis ei<strong>the</strong>r as separate liquid and char products or slurry of <strong>the</strong> two.<br />

Char is similar <strong>to</strong> coal in some respects being friable and having a relatively high calorific value,<br />

unfortunately it contains less than half of <strong>the</strong> energy value of <strong>the</strong> source material. Pyrolysis liquids are a<br />

mixture of complex carbohydrates and hydrocarbons that contain up <strong>to</strong> 70% of <strong>the</strong> energy of <strong>the</strong> source<br />

material. The relative proportions of char and liquids depend upon <strong>the</strong> reaction conditions in <strong>the</strong> process.<br />

Torrefied material. Torrefaction is <strong>the</strong> heat treatment of <strong>the</strong> material at temperatures between 200°C<br />

and 300°C that results in <strong>the</strong> removal of all moisture and a subsequent degradation and shrinkage of <strong>the</strong><br />

polymeric structure of <strong>the</strong> material. The changes produced <strong>by</strong> this process give an end product that is<br />

more energy dense, friable and less susceptible <strong>to</strong> take up moisture from its environment. These<br />

changes make it easier <strong>to</strong> transport, s<strong>to</strong>re and <strong>to</strong> use, particularly when pelletised. Torrefaction has <strong>the</strong><br />

advantage of producing a consistent fuel that retains over 90% of <strong>the</strong> energy of <strong>the</strong> source material.