to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

140<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

Upcoming projects include <strong>the</strong> Mytum & Sel<strong>by</strong> site, which is constructing a 25,000 <strong>to</strong>nnes per annum<br />

facility, due <strong>to</strong> be operatational <strong>by</strong> Oc<strong>to</strong>ber 2009. Phase two would see this capacity increase <strong>to</strong> 75,000<br />

<strong>to</strong>nnes per annum. 274<br />

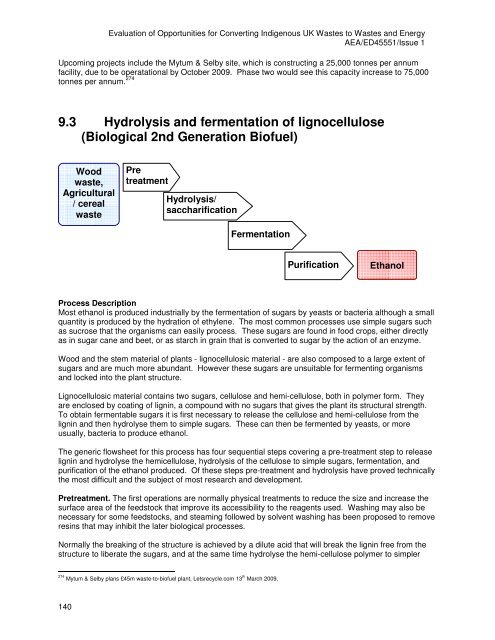

9.3 Hydrolysis and fermentation of lignocellulose<br />

(Biological 2nd Generation Biofuel)<br />

Wood<br />

waste,<br />

Agricultural<br />

/ cereal<br />

waste<br />

Pre<br />

treatment<br />

Hydrolysis/<br />

saccharification<br />

Fermentation<br />

Process Description<br />

Most ethanol is produced industrially <strong>by</strong> <strong>the</strong> fermentation of sugars <strong>by</strong> yeasts or bacteria although a small<br />

quantity is produced <strong>by</strong> <strong>the</strong> hydration of ethylene. The most common processes use simple sugars such<br />

as sucrose that <strong>the</strong> organisms can easily process. These sugars are found in food crops, ei<strong>the</strong>r directly<br />

as in sugar cane and beet, or as starch in grain that is converted <strong>to</strong> sugar <strong>by</strong> <strong>the</strong> action of an enzyme.<br />

Wood and <strong>the</strong> stem material of plants - lignocellulosic material - are also composed <strong>to</strong> a large extent of<br />

sugars and are much more abundant. However <strong>the</strong>se sugars are unsuitable for fermenting organisms<br />

and locked in<strong>to</strong> <strong>the</strong> plant structure.<br />

Lignocellulosic material contains two sugars, cellulose and hemi-cellulose, both in polymer form. They<br />

are enclosed <strong>by</strong> coating of lignin, a compound with no sugars that gives <strong>the</strong> plant its structural strength.<br />

To obtain fermentable sugars it is first necessary <strong>to</strong> release <strong>the</strong> cellulose and hemi-cellulose from <strong>the</strong><br />

lignin and <strong>the</strong>n hydrolyse <strong>the</strong>m <strong>to</strong> simple sugars. These can <strong>the</strong>n be fermented <strong>by</strong> yeasts, or more<br />

usually, bacteria <strong>to</strong> produce ethanol.<br />

The generic flowsheet for this process has four sequential steps covering a pre-treatment step <strong>to</strong> release<br />

lignin and hydrolyse <strong>the</strong> hemicellulose, hydrolysis of <strong>the</strong> cellulose <strong>to</strong> simple sugars, fermentation, and<br />

purification of <strong>the</strong> ethanol produced. Of <strong>the</strong>se steps pre-treatment and hydrolysis have proved technically<br />

<strong>the</strong> most difficult and <strong>the</strong> subject of most research and development.<br />

Pretreatment. The first operations are normally physical treatments <strong>to</strong> reduce <strong>the</strong> size and increase <strong>the</strong><br />

surface area of <strong>the</strong> feeds<strong>to</strong>ck that improve its accessibility <strong>to</strong> <strong>the</strong> reagents used. Washing may also be<br />

necessary for some feeds<strong>to</strong>cks, and steaming followed <strong>by</strong> solvent washing has been proposed <strong>to</strong> remove<br />

resins that may inhibit <strong>the</strong> later biological processes.<br />

Normally <strong>the</strong> breaking of <strong>the</strong> structure is achieved <strong>by</strong> a dilute acid that will break <strong>the</strong> lignin free from <strong>the</strong><br />

structure <strong>to</strong> liberate <strong>the</strong> sugars, and at <strong>the</strong> same time hydrolyse <strong>the</strong> hemi-cellulose polymer <strong>to</strong> simpler<br />

274 Mytum & Sel<strong>by</strong> plans £45m waste-<strong>to</strong>-biofuel plant, Letsrecycle.com 13 th March 2009.<br />

Purification<br />

Ethanol