to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

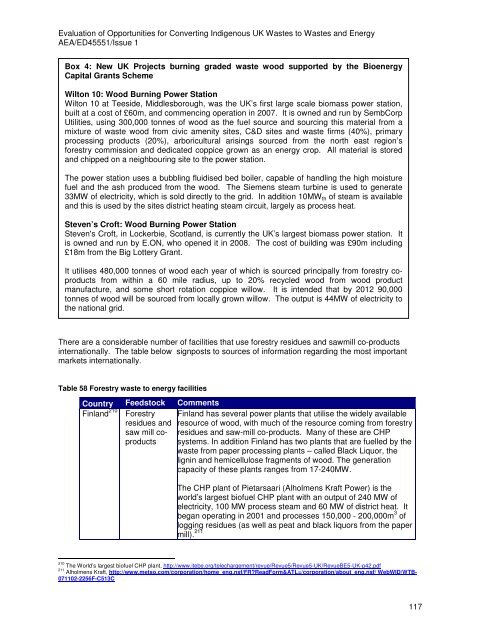

Box 4: New UK Projects burning graded waste wood supported <strong>by</strong> <strong>the</strong> Bioenergy<br />

Capital Grants Scheme<br />

Wil<strong>to</strong>n 10: Wood Burning Power Station<br />

Wil<strong>to</strong>n 10 at Teeside, Middlesborough, was <strong>the</strong> UK’s first large scale biomass power station,<br />

built at a cost of £60m, and commencing operation in 2007. It is owned and run <strong>by</strong> SembCorp<br />

Utilities, using 300,000 <strong>to</strong>nnes of wood as <strong>the</strong> fuel source and sourcing this material from a<br />

mixture of waste wood from civic amenity sites, C&D sites and waste firms (40%), primary<br />

processing products (20%), arboricultural arisings sourced from <strong>the</strong> north east region’s<br />

forestry commission and dedicated coppice grown as an energy crop. All material is s<strong>to</strong>red<br />

and chipped on a neighbouring site <strong>to</strong> <strong>the</strong> power station.<br />

The power station uses a bubbling fluidised bed boiler, capable of handling <strong>the</strong> high moisture<br />

fuel and <strong>the</strong> ash produced from <strong>the</strong> wood. The Siemens steam turbine is used <strong>to</strong> generate<br />

33MW of electricity, which is sold directly <strong>to</strong> <strong>the</strong> grid. In addition 10MWth of steam is available<br />

and this is used <strong>by</strong> <strong>the</strong> sites district heating steam circuit, largely as process heat.<br />

Steven’s Croft: Wood Burning Power Station<br />

Steven's Croft, in Lockerbie, Scotland, is currently <strong>the</strong> UK’s largest biomass power station. It<br />

is owned and run <strong>by</strong> E.ON, who opened it in 2008. The cost of building was £90m including<br />

£18m from <strong>the</strong> Big Lottery Grant.<br />

It utilises 480,000 <strong>to</strong>nnes of wood each year of which is sourced principally from forestry coproducts<br />

from within a 60 mile radius, up <strong>to</strong> 20% recycled wood from wood product<br />

manufacture, and some short rotation coppice willow. It is intended that <strong>by</strong> 2012 90,000<br />

<strong>to</strong>nnes of wood will be sourced from locally grown willow. The output is 44MW of electricity <strong>to</strong><br />

<strong>the</strong> national grid.<br />

There are a considerable number of facilities that use forestry residues and sawmill co-products<br />

internationally. The table below signposts <strong>to</strong> sources of information regarding <strong>the</strong> most important<br />

markets internationally.<br />

Table 58 Forestry waste <strong>to</strong> energy facilities<br />

Country Feeds<strong>to</strong>ck Comments<br />

Finland 210 Forestry<br />

residues and<br />

saw mill coproducts<br />

Finland has several power plants that utilise <strong>the</strong> widely available<br />

resource of wood, with much of <strong>the</strong> resource coming from forestry<br />

residues and saw-mill co-products. Many of <strong>the</strong>se are CHP<br />

systems. In addition Finland has two plants that are fuelled <strong>by</strong> <strong>the</strong><br />

waste from paper processing plants – called Black Liquor, <strong>the</strong><br />

lignin and hemicellulose fragments of wood. The generation<br />

capacity of <strong>the</strong>se plants ranges from 17-240MW.<br />

The CHP plant of Pietarsaari (Alholmens Kraft Power) is <strong>the</strong><br />

world’s largest biofuel CHP plant with an output of 240 MW of<br />

electricity, 100 MW process steam and 60 MW of district heat. It<br />

began operating in 2001 and processes 150,000 - 200,000m 3 of<br />

logging residues (as well as peat and black liquors from <strong>the</strong> paper<br />

mill). 211<br />

210 The World’s largest biofuel CHP plant, http://www.itebe.org/telechargement/revue/Revue5/Revue5-UK/RevueBE5-UK-p42.pdf<br />

211 Alholmens Kraft, http://www.metso.com/corporation/home_eng.nsf/FR?ReadForm&ATL=/corporation/about_eng.nsf/ WebWID/WTB-<br />

071102-2256F-C513C<br />

117