to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

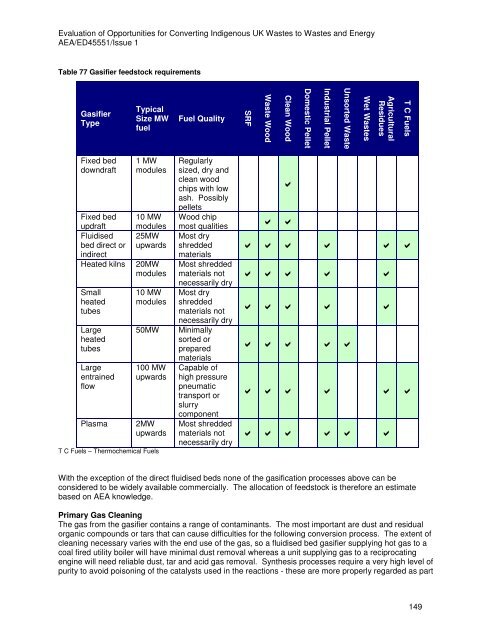

Table 77 Gasifier feeds<strong>to</strong>ck requirements<br />

Gasifier<br />

Type<br />

Fixed bed<br />

downdraft<br />

Typical<br />

Size MW<br />

fuel<br />

1 MW<br />

modules<br />

Fixed bed 10 MW<br />

updraft modules<br />

Fluidised 25MW<br />

bed direct or upwards<br />

indirect<br />

Heated kilns 20MW<br />

modules<br />

Small<br />

heated<br />

tubes<br />

Large<br />

heated<br />

tubes<br />

Large<br />

entrained<br />

flow<br />

10 MW<br />

modules<br />

Fuel Quality<br />

Regularly<br />

sized, dry and<br />

clean wood<br />

chips with low<br />

ash. Possibly<br />

pellets<br />

Wood chip<br />

SRF<br />

Waste Wood<br />

Clean Wood<br />

<br />

most qualities <br />

Most dry<br />

shredded<br />

materials<br />

Most shredded<br />

materials not<br />

necessarily dry<br />

Most dry<br />

shredded<br />

materials not<br />

necessarily dry<br />

50MW Minimally<br />

sorted or<br />

prepared<br />

100 MW<br />

upwards<br />

Plasma 2MW<br />

upwards<br />

T C Fuels – Thermochemical Fuels<br />

materials<br />

Capable of<br />

high pressure<br />

pneumatic<br />

transport or<br />

slurry<br />

component<br />

Most shredded<br />

materials not<br />

necessarily dry<br />

Domestic Pellet<br />

Industrial Pellet<br />

Unsorted Waste<br />

Wet Wastes<br />

Agricultural<br />

Residues<br />

T C Fuels<br />

<br />

<br />

<br />

<br />

<br />

<br />

With <strong>the</strong> exception of <strong>the</strong> direct fluidised beds none of <strong>the</strong> gasification processes above can be<br />

considered <strong>to</strong> be widely available commercially. The allocation of feeds<strong>to</strong>ck is <strong>the</strong>refore an estimate<br />

based on AEA knowledge.<br />

Primary Gas Cleaning<br />

The gas from <strong>the</strong> gasifier contains a range of contaminants. The most important are dust and residual<br />

organic compounds or tars that can cause difficulties for <strong>the</strong> following conversion process. The extent of<br />

cleaning necessary varies with <strong>the</strong> end use of <strong>the</strong> gas, so a fluidised bed gasifier supplying hot gas <strong>to</strong> a<br />

coal fired utility boiler will have minimal dust removal whereas a unit supplying gas <strong>to</strong> a reciprocating<br />

engine will need reliable dust, tar and acid gas removal. Syn<strong>the</strong>sis processes require a very high level of<br />

purity <strong>to</strong> avoid poisoning of <strong>the</strong> catalysts used in <strong>the</strong> reactions - <strong>the</strong>se are more properly regarded as part<br />

149