to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

<strong>the</strong> temperature of <strong>the</strong> reac<strong>to</strong>r and critically <strong>the</strong> rate at which heat is applied <strong>to</strong> <strong>the</strong> biomass fractions.<br />

Lower temperatures and fast heating rates favour vapours, higher temperatures and high heating rates<br />

gas, low temperature and slow heating rates favour char formation.<br />

There are two main categories of pyrolysis process, but many practical variants within <strong>the</strong>m:<br />

Fast or flash pyrolysis – typically finely divided biomass waste is injected in<strong>to</strong> a fluidised bed of inert<br />

material operating at 500°C. The size of <strong>the</strong> fuel and <strong>the</strong> excellent heat transfer characteristics of <strong>the</strong> fluid<br />

bed ensure a very fast heating rate which maximises <strong>the</strong> production of vapour. The vapour is<br />

subsequently condensed as a liquid that contains approximately 70% of <strong>the</strong> energy value of <strong>the</strong> waste<br />

feeds<strong>to</strong>ck. The <strong>by</strong>-product char and gas is used in part <strong>to</strong> provide heat <strong>to</strong> drive <strong>the</strong> process. The liquid<br />

fuel has been success<strong>full</strong>y used <strong>to</strong> fire boilers and kilns. Trials have been undertaken in reciprocating<br />

engines and gas turbines. Excess char can be sold as a product for activated carbon manufacture or<br />

reducing agent in metal production. The char can also be used as fuel ei<strong>the</strong>r on its own or as a slurry<br />

with <strong>the</strong> pyrolysis liquids.<br />

The main use for fast pyrolysis processes at present is <strong>the</strong> manufacture of speciality chemicals and food<br />

additives although this is expected <strong>to</strong> change <strong>to</strong> energy use when <strong>the</strong> current demonstration plants in<br />

Canada come <strong>full</strong>y on stream.<br />

Slow Pyrolysis – finely diced waste is pyrolysed in ei<strong>the</strong>r in a screw conveyor or reac<strong>to</strong>r vessel that is<br />

indirectly heated. The slower heating rate favours char and liquid production over gas.<br />

Carbonisation – large pieces of waste or wood are heated in a re<strong>to</strong>rt. The heat is provided <strong>by</strong> burning a<br />

proportion of <strong>the</strong> vapour and gas product.<br />

A variation of slow pyrolysis using a heated screw has recently been proposed as a step in <strong>the</strong> production<br />

of <strong>the</strong>rmo chemical fuels in <strong>the</strong> form of a slurry of charcoal and pyrolysis liquid product. The concept is a<br />

series of distributed fuel preparation processes on a local and regional scale that feed supply a very large<br />

gasification plant at national scale. The advantages are reduced transport costs and having <strong>the</strong> fuel in a<br />

form that it can easily be pumped in<strong>to</strong> <strong>the</strong> high pressure (60 bar) processes that are used in this type of<br />

facility.<br />

Feeds<strong>to</strong>cks for Pyrolysis<br />

Currently fast pyrolysis processes are being designed for both clean wood and wood extracted from <strong>the</strong><br />

waste stream. In all cases <strong>the</strong> wood will need <strong>to</strong> be ground <strong>to</strong> less that 3mm particle size before use.<br />

Slow pyrolysis can use a wider variety of solid shredded material including SRF.<br />

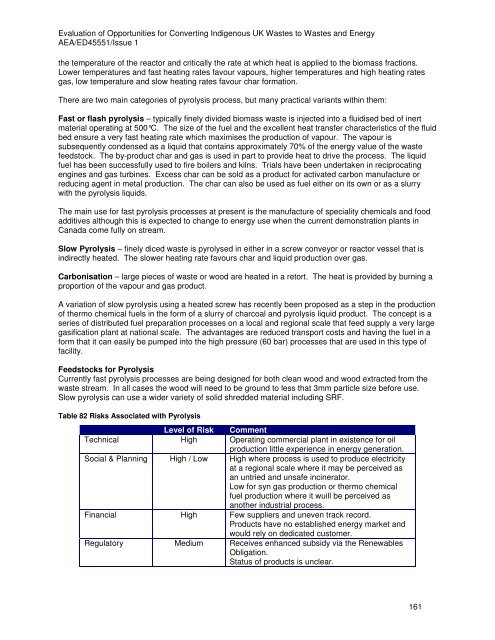

Table 82 Risks Associated with Pyrolysis<br />

Level of Risk Comment<br />

Technical High Operating commercial plant in existence for oil<br />

production little experience in energy generation.<br />

Social & Planning High / Low High where process is used <strong>to</strong> produce electricity<br />

at a regional scale where it may be perceived as<br />

an untried and unsafe incinera<strong>to</strong>r.<br />

Low for syn gas production or <strong>the</strong>rmo chemical<br />

fuel production where it wuill be perceived as<br />

ano<strong>the</strong>r industrial process.<br />

Financial High Few suppliers and uneven track record.<br />

Products have no established energy market and<br />

would rely on dedicated cus<strong>to</strong>mer.<br />

Regula<strong>to</strong>ry Medium Receives enhanced subsidy via <strong>the</strong> Renewables<br />

Obligation.<br />

Status of products is unclear.<br />

161