to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

158<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

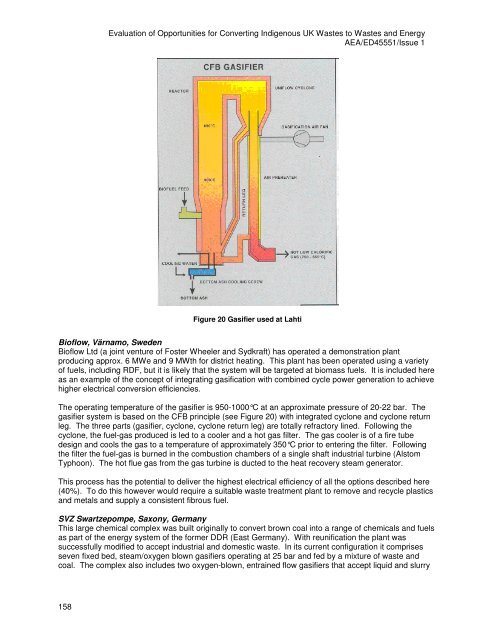

Figure 20 Gasifier used at Lahti<br />

Bioflow, Värnamo, Sweden<br />

Bioflow Ltd (a joint venture of Foster Wheeler and Sydkraft) has operated a demonstration plant<br />

producing approx. 6 MWe and 9 MWth for district heating. This plant has been operated using a variety<br />

of fuels, including RDF, but it is likely that <strong>the</strong> system will be targeted at biomass fuels. It is included here<br />

as an example of <strong>the</strong> concept of integrating gasification with combined cycle power generation <strong>to</strong> achieve<br />

higher electrical conversion efficiencies.<br />

The operating temperature of <strong>the</strong> gasifier is 950-1000°C at an approximate pressure of 20-22 bar. The<br />

gasifier system is based on <strong>the</strong> CFB principle (see Figure 20) with integrated cyclone and cyclone return<br />

leg. The three parts (gasifier, cyclone, cyclone return leg) are <strong>to</strong>tally refrac<strong>to</strong>ry lined. Following <strong>the</strong><br />

cyclone, <strong>the</strong> fuel-gas produced is led <strong>to</strong> a cooler and a hot gas filter. The gas cooler is of a fire tube<br />

design and cools <strong>the</strong> gas <strong>to</strong> a temperature of approximately 350°C prior <strong>to</strong> entering <strong>the</strong> filter. Following<br />

<strong>the</strong> filter <strong>the</strong> fuel-gas is burned in <strong>the</strong> combustion chambers of a single shaft industrial turbine (Als<strong>to</strong>m<br />

Typhoon). The hot flue gas from <strong>the</strong> gas turbine is ducted <strong>to</strong> <strong>the</strong> heat recovery steam genera<strong>to</strong>r.<br />

This process has <strong>the</strong> potential <strong>to</strong> deliver <strong>the</strong> highest electrical efficiency of all <strong>the</strong> options described here<br />

(40%). To do this however would require a suitable waste treatment plant <strong>to</strong> remove and recycle plastics<br />

and metals and supply a consistent fibrous fuel.<br />

SVZ Swartzepompe, Saxony, Germany<br />

This large chemical complex was built originally <strong>to</strong> convert brown coal in<strong>to</strong> a range of chemicals and fuels<br />

as part of <strong>the</strong> energy system of <strong>the</strong> former DDR (East Germany). With reunification <strong>the</strong> plant was<br />

success<strong>full</strong>y modified <strong>to</strong> accept industrial and domestic waste. In its current configuration it comprises<br />

seven fixed bed, steam/oxygen blown gasifiers operating at 25 bar and fed <strong>by</strong> a mixture of waste and<br />

coal. The complex also includes two oxygen-blown, entrained flow gasifiers that accept liquid and slurry