to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

120<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

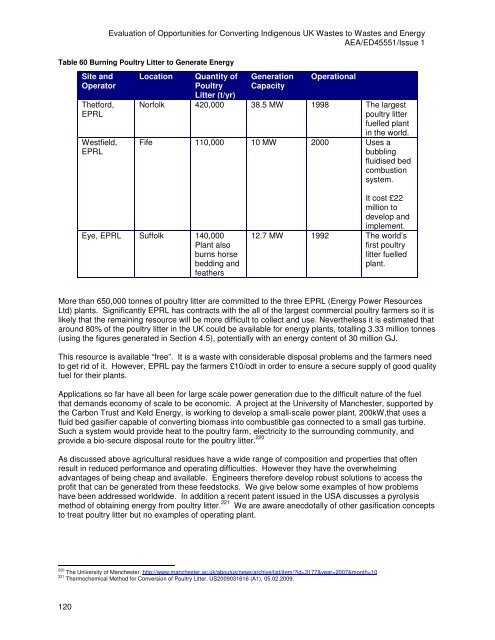

Table 60 Burning Poultry Litter <strong>to</strong> Generate Energy<br />

Site and<br />

Opera<strong>to</strong>r<br />

Thetford,<br />

EPRL<br />

Westfield,<br />

EPRL<br />

Location Quantity of<br />

Poultry<br />

Litter (t/yr)<br />

Generation<br />

Capacity<br />

Operational<br />

Norfolk 420,000 38.5 MW 1998 The largest<br />

poultry litter<br />

fuelled plant<br />

in <strong>the</strong> world.<br />

Fife 110,000 10 MW 2000 Uses a<br />

bubbling<br />

fluidised bed<br />

combustion<br />

system.<br />

Eye, EPRL Suffolk 140,000<br />

Plant also<br />

burns horse<br />

bedding and<br />

fea<strong>the</strong>rs<br />

It cost £22<br />

million <strong>to</strong><br />

develop and<br />

implement.<br />

12.7 MW 1992 The world’s<br />

first poultry<br />

litter fuelled<br />

plant.<br />

More than 650,000 <strong>to</strong>nnes of poultry litter are committed <strong>to</strong> <strong>the</strong> three EPRL (Energy Power Resources<br />

Ltd) plants. Significantly EPRL has contracts with <strong>the</strong> all of <strong>the</strong> largest commercial poultry farmers so it is<br />

likely that <strong>the</strong> remaining resource will be more difficult <strong>to</strong> collect and use. Never<strong>the</strong>less it is estimated that<br />

around 80% of <strong>the</strong> poultry litter in <strong>the</strong> UK could be available for energy plants, <strong>to</strong>talling 3.33 million <strong>to</strong>nnes<br />

(using <strong>the</strong> figures generated in Section 4.5), potentially with an energy content of 30 million GJ.<br />

This resource is available “free”. It is a waste with considerable disposal problems and <strong>the</strong> farmers need<br />

<strong>to</strong> get rid of it. However, EPRL pay <strong>the</strong> farmers £10/odt in order <strong>to</strong> ensure a secure supply of good quality<br />

fuel for <strong>the</strong>ir plants.<br />

Applications so far have all been for large scale power generation due <strong>to</strong> <strong>the</strong> difficult nature of <strong>the</strong> fuel<br />

that demands economy of scale <strong>to</strong> be economic. A project at <strong>the</strong> University of Manchester, supported <strong>by</strong><br />

<strong>the</strong> Carbon Trust and Keld Energy, is working <strong>to</strong> develop a small-scale power plant, 200kW,that uses a<br />

fluid bed gasifier capable of converting biomass in<strong>to</strong> combustible gas connected <strong>to</strong> a small gas turbine.<br />

Such a system would provide heat <strong>to</strong> <strong>the</strong> poultry farm, electricity <strong>to</strong> <strong>the</strong> surrounding community, and<br />

provide a bio-secure disposal route for <strong>the</strong> poultry litter. 220<br />

As discussed above agricultural residues have a wide range of composition and properties that often<br />

result in reduced performance and operating difficulties. However <strong>the</strong>y have <strong>the</strong> overwhelming<br />

advantages of being cheap and available. Engineers <strong>the</strong>refore develop robust solutions <strong>to</strong> access <strong>the</strong><br />

profit that can be generated from <strong>the</strong>se feeds<strong>to</strong>cks. We give below some examples of how problems<br />

have been addressed worldwide. In addition a recent patent issued in <strong>the</strong> USA discusses a pyrolysis<br />

method of obtaining energy from poultry litter. 221 We are aware anecdotally of o<strong>the</strong>r gasification concepts<br />

<strong>to</strong> treat poultry litter but no examples of operating plant.<br />

220 The University of Manchester, http://www.manchester.ac.uk/aboutus/news/archive/list/item/?id=3177&year=2007&month=10<br />

221 Thermochemical Method for Conversion of Poultry Litter, US2009031616 (A1), 05.02.2009.