to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

162<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

10.2.1 Pyrolysis in <strong>the</strong> UK<br />

Seamer Carr, Scarborough<br />

The UK’s first <strong>full</strong> scale waste pyrolysis plant is <strong>to</strong> be known as Scarborough Power Ltd. Once<br />

operational <strong>the</strong> plant will consume 18,000 <strong>to</strong>nnes per annum of high calorific value pre-sorted MSW, i.e. a<br />

form of SRF. 297 After shredding and drying <strong>the</strong> expected calorific content of this material will be 15MJ/kg.<br />

Simple flash pyrolysis, with technology provided <strong>by</strong> GEM, will be used <strong>to</strong> convert <strong>the</strong> waste <strong>to</strong> syngas in<br />

<strong>the</strong> absence of oxygen, which is <strong>the</strong>n ultimately used <strong>to</strong> generate electricity and heat, expected <strong>to</strong> be<br />

2.4MW of electricity and 1.8MW of gross heat output.<br />

This project is a joint venture between Yorwaste, pyrolysis technology company GEM, and engineering<br />

consultancy NEL Power, and is part of Defra’s New Technologies Demonstration Programme.<br />

Compact Power, Avonmouth<br />

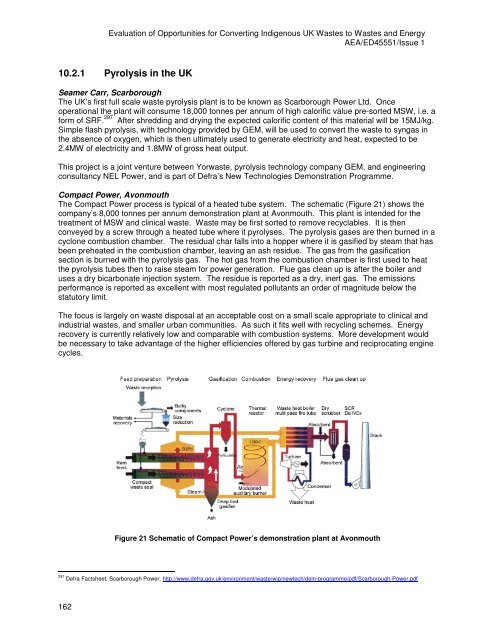

The Compact Power process is typical of a heated tube system. The schematic (Figure 21) shows <strong>the</strong><br />

company’s 8,000 <strong>to</strong>nnes per annum demonstration plant at Avonmouth. This plant is intended for <strong>the</strong><br />

treatment of MSW and clinical waste. Waste may be first sorted <strong>to</strong> remove recyclables. It is <strong>the</strong>n<br />

conveyed <strong>by</strong> a screw through a heated tube where it pyrolyses. The pyrolysis gases are <strong>the</strong>n burned in a<br />

cyclone combustion chamber. The residual char falls in<strong>to</strong> a hopper where it is gasified <strong>by</strong> steam that has<br />

been preheated in <strong>the</strong> combustion chamber, leaving an ash residue. The gas from <strong>the</strong> gasification<br />

section is burned with <strong>the</strong> pyrolysis gas. The hot gas from <strong>the</strong> combustion chamber is first used <strong>to</strong> heat<br />

<strong>the</strong> pyrolysis tubes <strong>the</strong>n <strong>to</strong> raise steam for power generation. Flue gas clean up is after <strong>the</strong> boiler and<br />

uses a dry bicarbonate injection system. The residue is <strong>report</strong>ed as a dry, inert gas. The emissions<br />

performance is <strong>report</strong>ed as excellent with most regulated pollutants an order of magnitude below <strong>the</strong><br />

statu<strong>to</strong>ry limit.<br />

The focus is largely on waste disposal at an acceptable cost on a small scale appropriate <strong>to</strong> clinical and<br />

industrial wastes, and smaller urban communities. As such it fits well with recycling schemes. Energy<br />

recovery is currently relatively low and comparable with combustion systems. More development would<br />

be necessary <strong>to</strong> take advantage of <strong>the</strong> higher efficiencies offered <strong>by</strong> gas turbine and reciprocating engine<br />

cycles.<br />

Figure 21 Schematic of Compact Power’s demonstration plant at Avonmouth<br />

297 Defra Factsheet, Scarborough Power, http://www.defra.gov.uk/environment/waste/wip/newtech/dem-programme/pdf/Scarborough-Power.pdf