to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

142<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

Current key <strong>to</strong>pics for research are <strong>the</strong> improvement of <strong>the</strong> organisms used in <strong>the</strong> process <strong>to</strong> improve<br />

yields and efficiency and <strong>the</strong> combination of several processes in <strong>the</strong> same unit operation <strong>to</strong> reduce<br />

capital costs.<br />

Current plans in <strong>the</strong> USA indicate that one of <strong>the</strong> most promising configurations for a demonstration will<br />

be <strong>to</strong> install <strong>the</strong> hydrolysis stages on a corn ethanol site <strong>to</strong> process <strong>the</strong> maize harvesting residue.<br />

Scale of operation – Regional<br />

The reliance on clean feeds<strong>to</strong>ck would suggest that this would be a regional technology drawing from<br />

agricultural residues such as straw and chipped wood fuels. The low bulk densities would tend <strong>to</strong> reduce<br />

<strong>the</strong> economic transport radius. However <strong>the</strong> process involves complex process engineering which<br />

responds well <strong>to</strong> <strong>the</strong> economies of scale.<br />

Hydrolysis feed s<strong>to</strong>cks<br />

Feed s<strong>to</strong>cks for hydrolysis based processes need <strong>to</strong> be clean waste, virgin wood or agricultural residues.<br />

The microbial fermentation is susceptible <strong>to</strong> poisoning if contaminated waste biomass is used as a<br />

feeds<strong>to</strong>ck.<br />

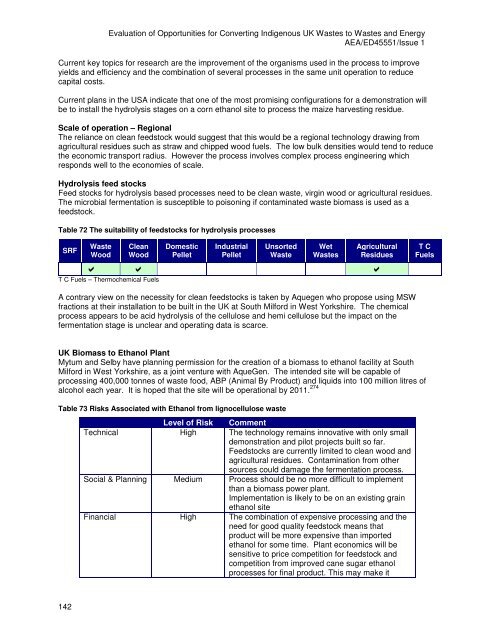

Table 72 The suitability of feeds<strong>to</strong>cks for hydrolysis processes<br />

SRF<br />

Waste<br />

Wood<br />

Clean<br />

Wood<br />

Domestic<br />

Pellet<br />

Industrial<br />

Pellet<br />

Unsorted<br />

Waste<br />

Wet<br />

Wastes<br />

Agricultural<br />

Residues<br />

<br />

T C Fuels – Thermochemical Fuels<br />

A contrary view on <strong>the</strong> necessity for clean feeds<strong>to</strong>cks is taken <strong>by</strong> Aquegen who propose using MSW<br />

fractions at <strong>the</strong>ir installation <strong>to</strong> be built in <strong>the</strong> UK at South Milford in West Yorkshire. The chemical<br />

process appears <strong>to</strong> be acid hydrolysis of <strong>the</strong> cellulose and hemi cellulose but <strong>the</strong> impact on <strong>the</strong><br />

fermentation stage is unclear and operating data is scarce.<br />

UK Biomass <strong>to</strong> Ethanol Plant<br />

Mytum and Sel<strong>by</strong> have planning permission for <strong>the</strong> creation of a biomass <strong>to</strong> ethanol facility at South<br />

Milford in West Yorkshire, as a joint venture with AqueGen. The intended site will be capable of<br />

processing 400,000 <strong>to</strong>nnes of waste food, ABP (Animal By Product) and liquids in<strong>to</strong> 100 million litres of<br />

alcohol each year. It is hoped that <strong>the</strong> site will be operational <strong>by</strong> 2011. 274<br />

Table 73 Risks Associated with Ethanol from lignocellulose waste<br />

Level of Risk Comment<br />

Technical High The technology remains innovative with only small<br />

demonstration and pilot projects built so far.<br />

Feeds<strong>to</strong>cks are currently limited <strong>to</strong> clean wood and<br />

agricultural residues. Contamination from o<strong>the</strong>r<br />

sources could damage <strong>the</strong> fermentation process.<br />

Social & Planning Medium Process should be no more difficult <strong>to</strong> implement<br />

than a biomass power plant.<br />

Implementation is likely <strong>to</strong> be on an existing grain<br />

ethanol site<br />

Financial High The combination of expensive processing and <strong>the</strong><br />

need for good quality feeds<strong>to</strong>ck means that<br />

product will be more expensive than imported<br />

ethanol for some time. Plant economics will be<br />

sensitive <strong>to</strong> price competition for feeds<strong>to</strong>ck and<br />

competition from improved cane sugar ethanol<br />

processes for final product. This may make it<br />

T C<br />

Fuels