to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

150<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

of <strong>the</strong> syn<strong>the</strong>sis package and so will be described below in that section. The requirements for <strong>the</strong> more<br />

demanding end uses have been summarised <strong>by</strong> <strong>the</strong> Karlsruhe Institute of Technology. 278 .<br />

Cleaning processes, especially those for <strong>the</strong> tars, have proved exceptionally difficult <strong>to</strong> design and<br />

implement in practice and are <strong>the</strong> principal cause of project failure where engines and gas turbines are<br />

used.<br />

Options that have shown success are:<br />

For tar removal<br />

• Catalytic cracking or steam reforming on limes<strong>to</strong>ne or nickel catalysts. (VTT, Condens)<br />

• Filtration on ceramic filter with limes<strong>to</strong>ne precoat. (Gussing, Biomass Engineering)<br />

• Liquid scrubbing with vegetable oil or biodiesel. (Gussing, Xylowatt)<br />

• Wet electrostatic precipita<strong>to</strong>rs (REFgas)<br />

• Plasma reaction chamber. (Europlasma)<br />

For dust removal<br />

• Ceramic, or sintered metal filters (Guessing, Biomass Engineering)<br />

• Cyclones<br />

• Liquid scrubbers with vegetable oil or biodiesel. (Gussing, Xylowatt)<br />

• Plasma reaction chamber. (Europlasma)<br />

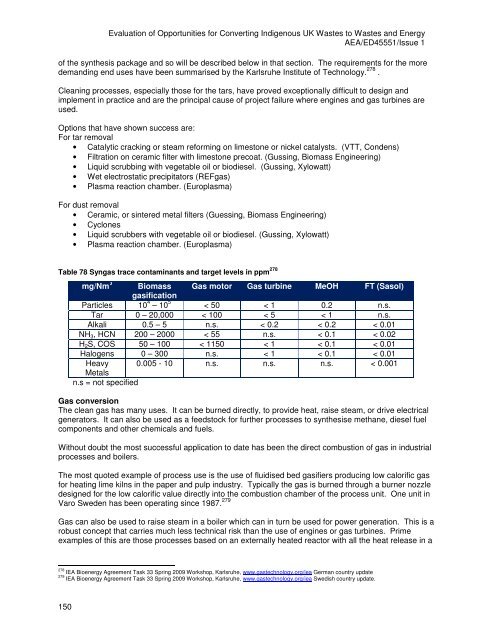

Table 78 Syngas trace contaminants and target levels in ppm 278<br />

mg/Nm 3 Biomass<br />

gasification<br />

Gas mo<strong>to</strong>r Gas turbine MeOH FT (Sasol)<br />

Particles 10 4 – 10 5 < 50 < 1 0.2 n.s.<br />

Tar 0 – 20,000 < 100 < 5 < 1 n.s.<br />

Alkali 0.5 – 5 n.s. < 0.2 < 0.2 < 0.01<br />

NH3, HCN 200 – 2000 < 55 n.s. < 0.1 < 0.02<br />

H2S, COS 50 – 100 < 1150 < 1 < 0.1 < 0.01<br />

Halogens 0 – 300 n.s. < 1 < 0.1 < 0.01<br />

Heavy<br />

Metals<br />

0.005 - 10 n.s. n.s. n.s. < 0.001<br />

n.s = not specified<br />

Gas conversion<br />

The clean gas has many uses. It can be burned directly, <strong>to</strong> provide heat, raise steam, or drive electrical<br />

genera<strong>to</strong>rs. It can also be used as a feeds<strong>to</strong>ck for fur<strong>the</strong>r processes <strong>to</strong> syn<strong>the</strong>sise methane, diesel fuel<br />

components and o<strong>the</strong>r chemicals and fuels.<br />

Without doubt <strong>the</strong> most successful application <strong>to</strong> date has been <strong>the</strong> direct combustion of gas in industrial<br />

processes and boilers.<br />

The most quoted example of process use is <strong>the</strong> use of fluidised bed gasifiers producing low calorific gas<br />

for heating lime kilns in <strong>the</strong> paper and pulp industry. Typically <strong>the</strong> gas is burned through a burner nozzle<br />

designed for <strong>the</strong> low calorific value directly in<strong>to</strong> <strong>the</strong> combustion chamber of <strong>the</strong> process unit. One unit in<br />

Varo Sweden has been operating since 1987. 279<br />

Gas can also be used <strong>to</strong> raise steam in a boiler which can in turn be used for power generation. This is a<br />

robust concept that carries much less technical risk than <strong>the</strong> use of engines or gas turbines. Prime<br />

examples of this are those processes based on an externally heated reac<strong>to</strong>r with all <strong>the</strong> heat release in a<br />

278 IEA Bioenergy Agreement Task 33 Spring 2009 Workshop, Karlsruhe, www.gastechnology.org/iea German country update<br />

279 IEA Bioenergy Agreement Task 33 Spring 2009 Workshop, Karlsruhe, www.gastechnology.org/iea Swedish country update.