to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

160<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

Plasma Gasification<br />

Plasma gasification is <strong>the</strong> gasification of matter in an oxygen-free environment <strong>to</strong> decompose waste<br />

material in<strong>to</strong> its basic molecular structure. It does not rely on incineration but converts organic waste in<strong>to</strong><br />

a fuel gas and inorganic waste in<strong>to</strong> an inert vitrified glass. In Japan <strong>the</strong> biggest industrial unit of its kind<br />

operates at <strong>the</strong> Eco-Valley site at Utashinai, Hokkaido plasma facility, built <strong>by</strong> Hitachi Metals. It began<br />

processing MSW in 2003 with a capacity of approximately 200-280 <strong>to</strong>ns per day. 293 It uses 8 Marc-3a<br />

plasma systems with <strong>to</strong>rches that are rated for 300 KW, operating at 2 gasification islands, each with 4<br />

<strong>to</strong>rches. The system delivers 1.5MW of net electricity output <strong>to</strong> <strong>the</strong> grid, 294 although <strong>the</strong> facility wasn’t<br />

designed with maximum power output in mind. If it had been, <strong>the</strong> predicted output would be 12MW. 295<br />

A second plasma gasification system operates in Japan, <strong>the</strong> Mihama-Mikata WTE Facility. The system<br />

gasifies 24 tpd of MSW and 4 tpd of waste-water sludge through 2 Marc-3a plasma systems. 294 The heat<br />

output is used within <strong>the</strong> waste water treatment facility.<br />

There are two plasma gasification plants under construction in India, at Pune and Nagpur, both intended<br />

<strong>to</strong> take 72 <strong>to</strong>ns per day of hazardous waste and convert it <strong>to</strong> energy.<br />

A plasma gasifier has planning permission in <strong>the</strong> USA, Florida where it is intended that 3,000 <strong>to</strong>ns per<br />

day of MSW will be converted <strong>to</strong> 120MW of electricity and is expected <strong>to</strong> be operational in 2010. 296<br />

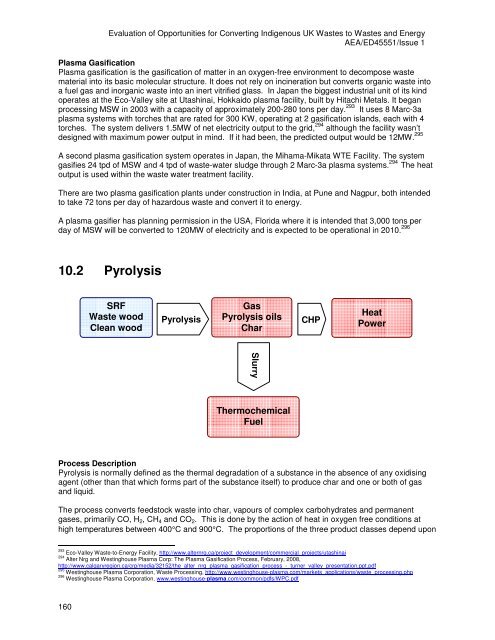

10.2 Pyrolysis<br />

SRF<br />

Waste wood<br />

Clean wood<br />

Pyrolysis<br />

Gas<br />

Pyrolysis oils<br />

Char<br />

Process Description<br />

Pyrolysis is normally defined as <strong>the</strong> <strong>the</strong>rmal degradation of a substance in <strong>the</strong> absence of any oxidising<br />

agent (o<strong>the</strong>r than that which forms part of <strong>the</strong> substance itself) <strong>to</strong> produce char and one or both of gas<br />

and liquid.<br />

The process converts feeds<strong>to</strong>ck waste in<strong>to</strong> char, vapours of complex carbohydrates and permanent<br />

gases, primarily CO, H2, CH4 and CO2. This is done <strong>by</strong> <strong>the</strong> action of heat in oxygen free conditions at<br />

high temperatures between 400°C and 900°C. The proportions of <strong>the</strong> three product classes depend upon<br />

CHP<br />

293 Eco-Valley Waste-<strong>to</strong>-Energy Facility, http://www.alternrg.ca/project_development/commercial_projects/utashinai<br />

294 Alter Nrg and Westinghouse Plasma Corp: The Plasma Gasification Process, February, 2008,<br />

http://www.calgaryregion.ca/crp/media/32152/<strong>the</strong>_alter_nrg_plasma_gasification_process_-_turner_valley_presentation.ppt.pdf<br />

295 Westinghouse Plasma Corporation, Waste Processing, http://www.westinghouse-plasma.com/markets_applications/waste_processing.php<br />

296 Westinghouse Plasma Corporation, www.westinghouse-plasma.com/common/pdfs/WPC.pdf<br />

Slurry<br />

Thermochemical<br />

Fuel<br />

Heat<br />

Power