to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

146<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

Gasification has been success<strong>full</strong>y used with coal, in <strong>the</strong> American Great Plains project <strong>to</strong> generate<br />

syn<strong>the</strong>tic natural gas and in South Africa <strong>to</strong> generate transport fuels. There are also instances<br />

internationally where gasification has been used with SRF waste as a feeds<strong>to</strong>ck.<br />

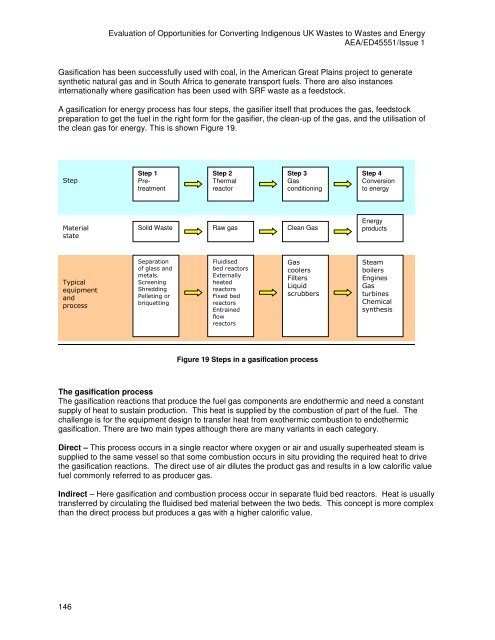

A gasification for energy process has four steps, <strong>the</strong> gasifier itself that produces <strong>the</strong> gas, feeds<strong>to</strong>ck<br />

preparation <strong>to</strong> get <strong>the</strong> fuel in <strong>the</strong> right form for <strong>the</strong> gasifier, <strong>the</strong> clean-up of <strong>the</strong> gas, and <strong>the</strong> utilisation of<br />

<strong>the</strong> clean gas for energy. This is shown Figure 19.<br />

Step<br />

Material<br />

state<br />

Typical<br />

equipment<br />

and<br />

process<br />

Step 1<br />

Pretreatment<br />

Step 2<br />

Thermal<br />

reac<strong>to</strong>r<br />

Step 3<br />

Gas<br />

conditioning<br />

Solid Waste Raw gas<br />

Clean Gas<br />

Separation<br />

of glass and<br />

metals.<br />

Screening<br />

Shredding<br />

Pelleting or<br />

briquetting<br />

Fluidised<br />

bed reac<strong>to</strong>rs<br />

Externally<br />

heated<br />

reac<strong>to</strong>rs<br />

Fixed bed<br />

reac<strong>to</strong>rs<br />

Entrained<br />

flow<br />

reac<strong>to</strong>rs<br />

Gas<br />

coolers<br />

Filters<br />

Liquid<br />

scrubbers<br />

Figure 19 Steps in a gasification process<br />

Step 4<br />

Conversion<br />

<strong>to</strong> energy<br />

Energy<br />

products<br />

Steam<br />

boilers<br />

Engines<br />

Gas<br />

turbines<br />

Chemical<br />

syn<strong>the</strong>sis<br />

The gasification process<br />

The gasification reactions that produce <strong>the</strong> fuel gas components are endo<strong>the</strong>rmic and need a constant<br />

supply of heat <strong>to</strong> sustain production. This heat is supplied <strong>by</strong> <strong>the</strong> combustion of part of <strong>the</strong> fuel. The<br />

challenge is for <strong>the</strong> equipment design <strong>to</strong> transfer heat from exo<strong>the</strong>rmic combustion <strong>to</strong> endo<strong>the</strong>rmic<br />

gasification. There are two main types although <strong>the</strong>re are many variants in each category.<br />

Direct – This process occurs in a single reac<strong>to</strong>r where oxygen or air and usually superheated steam is<br />

supplied <strong>to</strong> <strong>the</strong> same vessel so that some combustion occurs in situ providing <strong>the</strong> required heat <strong>to</strong> drive<br />

<strong>the</strong> gasification reactions. The direct use of air dilutes <strong>the</strong> product gas and results in a low calorific value<br />

fuel commonly referred <strong>to</strong> as producer gas.<br />

Indirect – Here gasification and combustion process occur in separate fluid bed reac<strong>to</strong>rs. Heat is usually<br />

transferred <strong>by</strong> circulating <strong>the</strong> fluidised bed material between <strong>the</strong> two beds. This concept is more complex<br />

than <strong>the</strong> direct process but produces a gas with a higher calorific value.