to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

to read the full report - Ecolateral by Peter Jones

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

156<br />

Evaluation of Opportunities for Converting Indigenous UK Wastes <strong>to</strong> Wastes and Energy<br />

AEA/ED45551/Issue 1<br />

10.1.4 International Situation<br />

Gasification<br />

There are a few projects using <strong>the</strong> Energos technology for example <strong>the</strong> plant at Averøy in Norway. The Averøy plant<br />

opened in 2000 and processes 30,000 <strong>to</strong>nnes of MSW each year, <strong>the</strong> power output of which is used <strong>by</strong> a<br />

neighbouring fac<strong>to</strong>ry. 289 A fur<strong>the</strong>r Energos site in Norway is in Forus, receiving 40,000 <strong>to</strong>nnes per annum<br />

of residual waste since 2002.<br />

Japan has an established his<strong>to</strong>ry of gasification, with <strong>the</strong> first Thermoselect plant built at Chiba in 1999 <strong>by</strong><br />

Kawasaki Steel Corporation (now known as JFE). There are now seven plants (a <strong>to</strong>tal of 16 Thermoselect<br />

units) in operation with a <strong>to</strong>tal daily capacity of nearly 2,000 <strong>to</strong>nnes. The availability of <strong>the</strong> operating<br />

plants is about 80%. The syngas produced in <strong>the</strong> Thermoselect furnace is quenched and cleaned before<br />

it is used in gas turbines or engines. The amount of useful gas produced per <strong>to</strong>nne of MSW processed is<br />

much lower than in conventional combustion and steam generation units as cleaning a reducing gas is<br />

more complex than for combustion process gas.<br />

In <strong>the</strong> Thermoselect process waste is pushed through a heated tube. The residual char is gasified and<br />

<strong>the</strong> gases mixed, <strong>the</strong> gasification agent is oxygen which gives a high enough temperature <strong>to</strong> convert <strong>the</strong><br />

ash <strong>to</strong> slag. The mixed gases <strong>the</strong>n pass through a waste heat boiler and scrubber before being burned in<br />

a steam boiler.<br />

Currently electrical efficiencies are ra<strong>the</strong>r low at but <strong>the</strong> Japanese licensee is carrying out trials using <strong>the</strong><br />

higher calorific value gases from <strong>the</strong> reac<strong>to</strong>r with reciprocating engines and fuel cells ra<strong>the</strong>r than boilers,<br />

which should significantly improve <strong>the</strong> electrical efficiency of <strong>the</strong> process.<br />

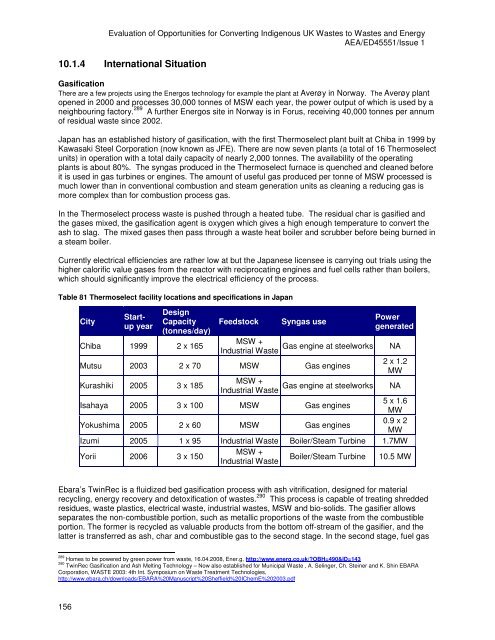

Table 81 Thermoselect facility locations and specifications in Japan<br />

City<br />

Startup<br />

year<br />

Design<br />

Capacity<br />

(<strong>to</strong>nnes/day)<br />

Feeds<strong>to</strong>ck Syngas use<br />

Power<br />

generated<br />

Chiba 1999 2 x 165<br />

MSW +<br />

Gas engine at steelworks<br />

Industrial Waste<br />

NA<br />

Mutsu 2003 2 x 70 MSW Gas engines<br />

2 x 1.2<br />

MW<br />

Kurashiki 2005 3 x 185<br />

MSW +<br />

Gas engine at steelworks<br />

Industrial Waste<br />

NA<br />

Isahaya 2005 3 x 100 MSW Gas engines<br />

5 x 1.6<br />

MW<br />

Yokushima 2005 2 x 60 MSW Gas engines<br />

0.9 x 2<br />

MW<br />

Izumi 2005 1 x 95 Industrial Waste Boiler/Steam Turbine 1.7MW<br />

Yorii 2006 3 x 150<br />

MSW +<br />

Industrial Waste<br />

Boiler/Steam Turbine 10.5 MW<br />

Ebara’s TwinRec is a fluidized bed gasification process with ash vitrification, designed for material<br />

recycling, energy recovery and de<strong>to</strong>xification of wastes. 290 This process is capable of treating shredded<br />

residues, waste plastics, electrical waste, industrial wastes, MSW and bio-solids. The gasifier allows<br />

separates <strong>the</strong> non-combustible portion, such as metallic proportions of <strong>the</strong> waste from <strong>the</strong> combustible<br />

portion. The former is recycled as valuable products from <strong>the</strong> bot<strong>to</strong>m off-stream of <strong>the</strong> gasifier, and <strong>the</strong><br />

latter is transferred as ash, char and combustible gas <strong>to</strong> <strong>the</strong> second stage. In <strong>the</strong> second stage, fuel gas<br />

289 Homes <strong>to</strong> be powered <strong>by</strong> green power from waste, 16.04.2008, Ener.g, http://www.energ.co.uk/?OBH=490&ID=143<br />

290 TwinRec Gasification and Ash Melting Technology – Now also established for Municipal Waste , A. Selinger, Ch. Steiner and K. Shin EBARA<br />

Corporation, WASTE 2003: 4th Int. Symposium on Waste Treatment Technologies,<br />

http://www.ebara.ch/downloads/EBARA%20Manuscript%20Sheffield%20IChemE%202003.pdf