Service Manual TNC 407 / TNC 415 - heidenhain - DR. JOHANNES ...

Service Manual TNC 407 / TNC 415 - heidenhain - DR. JOHANNES ...

Service Manual TNC 407 / TNC 415 - heidenhain - DR. JOHANNES ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Kundendienst<br />

HElDENHAlN<br />

<strong>DR</strong> <strong>JOHANNES</strong> HElDENHAlN GmbH<br />

D-~3292T~aunre"t.~"108669) 31-o<br />

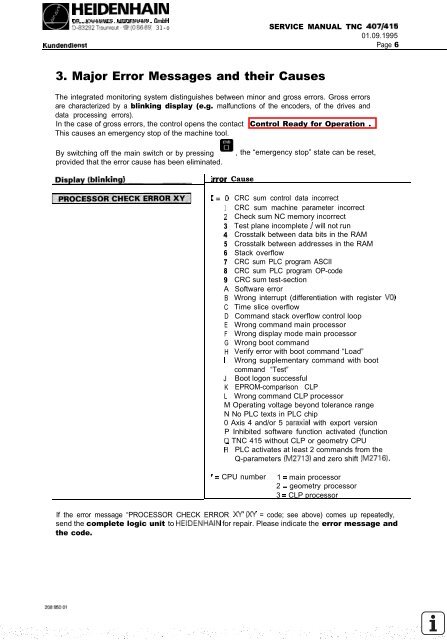

3. Major Error Messages and their Causes<br />

SERVICE MANUAL <strong>TNC</strong> <strong>407</strong>1<strong>415</strong><br />

01.09.1995<br />

Page 6<br />

The integrated monitoring system distinguishes between minor and gross errors. Gross errors<br />

are characterized by a blinking display (e.g. malfunctions of the encoders, of the drives and<br />

data processing errors).<br />

In the case of gross errors, the control opens the contact “Control Ready for Operation”.<br />

This causes an emergency stop of the machine tool.<br />

By switching off the main switch or by pressing #II, the “emergency stop” state can be reset,<br />

provided that the error cause has been eliminated.<br />

:rror Cause<br />

:= 0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

I<br />

CRC sum control data incorrect<br />

CRC sum machine parameter incorrect<br />

Check sum NC memory incorrect<br />

Test plane incomplete I will not run<br />

Crosstalk between data bits in the RAM<br />

Crosstalk between addresses in the RAM<br />

Stack overflow<br />

CRC sum PLC program ASCII<br />

CRC sum PLC program OP-code<br />

CRC sum test-section<br />

Software error<br />

Wrong interrupt (differentiation with register VO)<br />

Time slice overflow<br />

Command stack overflow control loop<br />

Wrong command main processor<br />

Wrong display mode main processor<br />

Wrong boot command<br />

Verify error with boot command “Load”<br />

Wrong supplementary command with boot<br />

command “Test”<br />

J Boot logon successful<br />

K EPROM-comparison CLP<br />

L Wrong command CLP processor<br />

M Operating voltage beyond tolerance range<br />

N No PLC texts in PLC chip<br />

0 Axis 4 and/or 5 paraxial with export version<br />

P Inhibited software function activated (function<br />

Q <strong>TNC</strong> <strong>415</strong> without CLP or geometry CPU<br />

R PLC activates at least 2 commands from the<br />

Q-parameters CM27131 and zero shift fM2716).<br />

’ = CPU number 1 = main processor<br />

2 = geometry processor<br />

3 = CLP processor<br />

If the error message “PROCESSOR CHECK ERROR XY” (XY = code; see above) comes up repeatedly,<br />

send the complete logic unit to HEIDENHAIN for repair. Please indicate the error message and<br />

the code.