num parameter manual - Documentation CN

num parameter manual - Documentation CN

num parameter manual - Documentation CN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A<br />

Acceleration 6-10, 6-43<br />

Acceleration anticipation 6-34<br />

Allocation<br />

calibration table 9-14<br />

programme stack 9-14<br />

Approach speed 6-36<br />

ASCII character string 1-5<br />

Auto recall after INTERV 9-28<br />

Automatic speed range search 9-6<br />

Axes<br />

carried 4-34<br />

carrier 4-34<br />

clamped 4-22<br />

<strong>CN</strong>C 4-24<br />

controlled by QDD 12-8<br />

displayed 4-10<br />

interpolated 4-14<br />

limited excursion 4-12<br />

measured 4-8<br />

modulo 4-12<br />

PLC 4-24<br />

programmable by diameter 4-18<br />

servo-controlled 4-14<br />

with quantified movement 4-36<br />

Axis<br />

Axis assignment 4-24<br />

drive 4-30, 4-32<br />

driven 4-30, 4-32, 6-30<br />

Axis group 4-6<br />

<strong>CN</strong>C 4-6, 4-24<br />

Axis group configuration 4-16<br />

lathe 4-16<br />

milling machine 4-16<br />

PLC 4-6, 4-24<br />

Axis travel 7-12<br />

B<br />

Backlash error 7-14<br />

Backup in path 9-28<br />

Ball-Bar programme 6-46, 6-47<br />

Block execution time 9-12<br />

C<br />

Calibration table enable 9-6<br />

Calibration table writing 9-6<br />

Channel complementarity 5-16<br />

Checking<br />

homing 7-17<br />

speeds 11-3<br />

Coefficient<br />

measurement conversion 5-6, 5-12<br />

servo-control 6-14<br />

speed anticipation 6-26<br />

Colour chart 9-16<br />

D<br />

Data tables 4-3, 5-3, 6-3, 7-3, 8-3, 9-3<br />

Direction<br />

axis measurement 5-4<br />

handwheel measurement 5-10<br />

homing 7-8<br />

speed reference 6-12<br />

DIVI 5-6, 5-10<br />

DNC1 character formatting 10-2<br />

DNC1 timeouts 10-6<br />

DNC1000 timeout 10-8<br />

Dry friction correction amplitude 6-34<br />

Dry friction correction time constant 6-35<br />

Dry friction elimination 6-35<br />

Duplicated axis coupling 4-30<br />

Dynamic movement control 6-24, 11-8<br />

E<br />

EMAX 6-23, 6-44, 11-6<br />

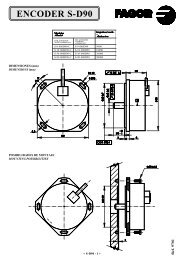

Encoder channel complementarity 5-12, 5-14<br />

F<br />

Following error 6-22<br />

Functions<br />

Decoded M and T functions 9-6<br />

Miscellaneous functions 9-6<br />

G<br />

Gain 6-18, 8-30<br />

Graduation 5-22<br />

Graphic elements 9-16<br />

H<br />

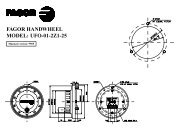

Handwheels 4-28<br />

Homing on datum switch 7-5<br />

I<br />

Improving the settings 11-6<br />

Incremental rules with encoded reference<br />

marks 5-22<br />

In-position window 6-20, 11-7<br />

indexing 8-28<br />

Indexed stop 8-5<br />

Indexing<br />

bidirectional 8-4<br />

spindle 8-4<br />

K<br />

KVAR 6-14, 6-44, 11-6<br />

L<br />

Index<br />

Limit switches 7-12<br />

List of machine setup data 2-1<br />

M<br />

MAPWAY/ETHWAY 10-10<br />

Measurement<br />

spindle 8-14<br />

unit, internal 4-18, 6-15, 6-23<br />

Measurement sensor <strong>parameter</strong>s 5-18<br />

Measurement sensor type 5-18<br />

Mechanical backlash 7-14<br />

Memory areas 9-20<br />

Minimum spindle speed reference in hole<br />

bottom 8-32<br />

MULTI 5-6, 5-10<br />

N<br />

Network <strong>num</strong>ber 10-10<br />

Number of graduations 5-22<br />

O<br />

ORPOM 7-10<br />

P<br />

Index<br />

P0 4-10<br />

P1 4-12<br />

P10 5-4<br />

P100 10-10<br />

P11 5-6<br />

P110 10-12<br />

P111 10-16<br />

P112 10-20<br />

P114 9-28<br />

P12 5-10<br />

P13 5-12<br />

P14 4-28<br />

P15 7-8<br />

P16 7-10<br />

P17 7-12<br />

P18 7-14<br />

P19 6-34<br />

P2 4-8<br />

P20 6-12<br />

P21 6-14, 12-1<br />

P22 6-20<br />

P23 6-22<br />

P24 6-30<br />

P25 5-14, 5-16<br />

P26 5-16<br />

P27 4-30<br />

P28 4-32<br />

P3 4-14<br />

en-938818/7 I - 1