Microseismic Monitoring and Geomechanical Modelling of CO2 - bris

Microseismic Monitoring and Geomechanical Modelling of CO2 - bris

Microseismic Monitoring and Geomechanical Modelling of CO2 - bris

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CHAPTER 4. A COMPARISON OF MICROSEISMIC MONITORING OF FRACTURE STIMULATION DUE TO WATER<br />

VERSUS CO 2 INJECTION<br />

200<br />

150<br />

Recording well<br />

Injection well<br />

2400<br />

2500<br />

Perf shots<br />

Geophones<br />

Northing (m)<br />

100<br />

50<br />

Depth (m)<br />

2600<br />

2700<br />

2800<br />

0<br />

2900<br />

−50<br />

−50 0 50 100 150 200<br />

Easting (m)<br />

(a)<br />

3000<br />

−50 0 50 100 150 200<br />

Easting (m)<br />

(b)<br />

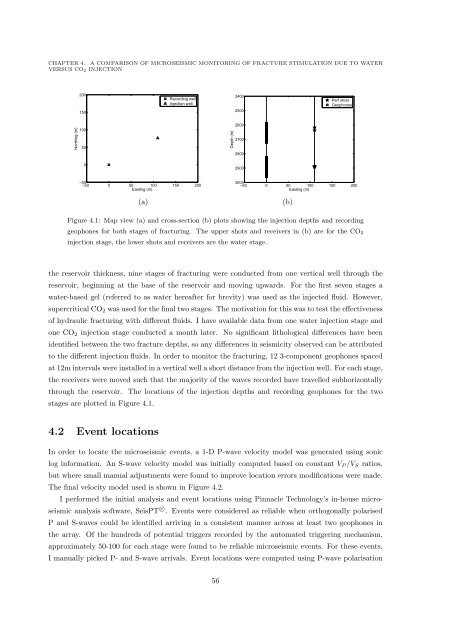

Figure 4.1: Map view (a) <strong>and</strong> cross-section (b) plots showing the injection depths <strong>and</strong> recording<br />

geophones for both stages <strong>of</strong> fracturing. The upper shots <strong>and</strong> receivers in (b) are for the CO 2<br />

injection stage, the lower shots <strong>and</strong> receivers are the water stage.<br />

the reservoir thickness, nine stages <strong>of</strong> fracturing were conducted from one vertical well through the<br />

reservoir, beginning at the base <strong>of</strong> the reservoir <strong>and</strong> moving upwards. For the first seven stages a<br />

water-based gel (referred to as water hereafter for brevity) was used as the injected fluid. However,<br />

supercritical CO 2 was used for the final two stages. The motivation for this was to test the effectiveness<br />

<strong>of</strong> hydraulic fracturing with different fluids. I have available data from one water injection stage <strong>and</strong><br />

one CO 2 injection stage conducted a month later. No significant lithological differences have been<br />

identified between the two fracture depths, so any differences in seismicity observed can be attributed<br />

to the different injection fluids. In order to monitor the fracturing, 12 3-component geophones spaced<br />

at 12m intervals were installed in a vertical well a short distance from the injection well. For each stage,<br />

the receivers were moved such that the majority <strong>of</strong> the waves recorded have travelled subhorizontally<br />

through the reservoir. The locations <strong>of</strong> the injection depths <strong>and</strong> recording geophones for the two<br />

stages are plotted in Figure 4.1.<br />

4.2 Event locations<br />

In order to locate the microseismic events, a 1-D P-wave velocity model was generated using sonic<br />

log information. An S-wave velocity model was initially computed based on constant V P /V S ratios,<br />

but where small manual adjustments were found to improve location errors modifications were made.<br />

The final velocity model used is shown in Figure 4.2.<br />

I performed the initial analysis <strong>and</strong> event locations using Pinnacle Technology’s in-house microseismic<br />

analysis s<strong>of</strong>tware, SeisPT c⃝ . Events were considered as reliable when orthogonally polarised<br />

P <strong>and</strong> S-waves could be identified arriving in a consistent manner across at least two geophones in<br />

the array. Of the hundreds <strong>of</strong> potential triggers recorded by the automated triggering mechanism,<br />

approximately 50-100 for each stage were found to be reliable microseismic events. For these events,<br />

I manually picked P- <strong>and</strong> S-wave arrivals. Event locations were computed using P-wave polarisation<br />

56