- Page 1 and 2:

Metal Forming Handbook /Schuler (c)

- Page 3 and 4:

123 METAL FORMING Metal Forming Han

- Page 5 and 6:

Preface Following the long traditio

- Page 7 and 8:

Contributors ADAM, K., Dipl.-Ing. (

- Page 9 and 10:

Contents Index of formula symbols .

- Page 11 and 12:

Contents 3.6.5 Measures to be under

- Page 13 and 14:

Contents 5.3 Component development

- Page 15 and 16:

Index of formula symbols � rib an

- Page 17 and 18:

Index of formular symbols d inner d

- Page 19 and 20:

Index of formular symbols p G avera

- Page 21 and 22:

1 Introduction Technology has exert

- Page 23 and 24:

Introduction Fig. 1.1 L. Schuler, M

- Page 25 and 26:

2 Basic principles of metal forming

- Page 27 and 28:

Methods of forming and cutting tech

- Page 29 and 30:

Methods of forming and cutting tech

- Page 31 and 32:

Methods of forming and cutting tech

- Page 33 and 34:

Methods of forming and cutting tech

- Page 35 and 36:

Methods of forming and cutting tech

- Page 37 and 38:

Methods of forming and cutting tech

- Page 39 and 40:

Methods of forming and cutting tech

- Page 41 and 42:

Methods of forming and cutting tech

- Page 43 and 44:

Methods of forming and cutting tech

- Page 45 and 46:

2 Basic principles of metal forming

- Page 47 and 48:

Basic terms in which � 1 is defor

- Page 49 and 50:

Basic terms cation of an exterior f

- Page 51 and 52:

Basic terms fracture, this characte

- Page 53 and 54:

3 Fundamentals of press design 3.1

- Page 55 and 56:

Press types and press construction

- Page 57 and 58:

Press types and press construction

- Page 59 and 60:

Press types and press construction

- Page 61 and 62:

Press types and press construction

- Page 63 and 64:

Press types and press construction

- Page 65 and 66:

Press types and press construction

- Page 67 and 68:

Press types and press construction

- Page 69 and 70:

3 Fundamentals of press design 3.2

- Page 71 and 72:

Mechanical presses , distance s[m]

- Page 73 and 74:

Mechanical presses stress on the fr

- Page 75 and 76:

Mechanical presses stroke [mm] 900

- Page 77 and 78:

Mechanical presses This offers a nu

- Page 79 and 80:

Mechanical presses or bottom mounte

- Page 81 and 82:

Mechanical presses In crossbar tran

- Page 83 and 84:

Mechanical presses with a long serv

- Page 85 and 86:

Mechanical presses Fig. 3.2.9 Drive

- Page 87 and 88:

Mechanical presses Overload safety

- Page 89 and 90:

Mechanical presses Slide cushion So

- Page 91 and 92:

Mechanical presses imum pneumatic p

- Page 93 and 94:

3 Fundamentals of press design 3.3

- Page 95 and 96:

Hydraulic presses Design of the dri

- Page 97 and 98:

Hydraulic presses pumps suspended i

- Page 99 and 100:

Hydraulic presses pressure in the p

- Page 101 and 102:

Hydraulic presses F 4 I P (F ) max

- Page 103 and 104:

Hydraulic presses are two variation

- Page 105 and 106:

Hydraulic presses presscrown retain

- Page 107 and 108:

Changing dies to a weight of 3 t pr

- Page 109 and 110:

Changing dies gearwithguidinggroove

- Page 111 and 112:

Changing dies are changed in solid

- Page 113 and 114:

Changing dies hydraulic clamping me

- Page 115 and 116:

Press control systems 3.5.3 Operati

- Page 117 and 118:

Press control systems 3.5.4 Structu

- Page 119 and 120:

Press control systems The communica

- Page 121 and 122:

Press control systems Fig. 3.5.5 PL

- Page 123 and 124:

Press control systems Fig. 3.5.7 Sw

- Page 125 and 126:

Press control systems Other approac

- Page 127 and 128:

Press safety and certification 3.6.

- Page 129 and 130:

Press safety and certification with

- Page 131 and 132:

Press safety and certification - st

- Page 133 and 134:

Press safety and certification Manu

- Page 135 and 136:

Press safety and certification pres

- Page 137 and 138:

Press safety and certification 3.6.

- Page 139 and 140:

Press safety and certification tion

- Page 141 and 142:

Casting components for presses Fig.

- Page 143 and 144:

4 Sheet metal forming and blanking

- Page 145 and 146:

Principles of die manufacture icall

- Page 147 and 148:

Principles of die manufacture becau

- Page 149 and 150:

Principles of die manufacture go-ah

- Page 151 and 152:

Principles of die manufacture produ

- Page 153 and 154:

Principles of die manufacture Fig.

- Page 155 and 156:

Principles of die manufacture a b c

- Page 157 and 158:

Principles of die manufacture the p

- Page 159 and 160:

Metal Forming Handbook / Schuler (c

- Page 161 and 162:

Principles of die manufacture 0.00

- Page 163 and 164:

Principles of die manufacture blank

- Page 165 and 166:

Metal Forming Handbook / Schuler (c

- Page 167 and 168:

Principles of die manufacture Fig.

- Page 169 and 170:

Principles of die manufacture how i

- Page 171 and 172:

Principles of die manufacture spott

- Page 173 and 174:

Principles of die manufacture Fig.

- Page 175 and 176:

Principles of die manufacture Fig.

- Page 177 and 178:

Deep drawing and stretch drawing me

- Page 179 and 180:

Deep drawing and stretch drawing In

- Page 181 and 182:

Deep drawing and stretch drawing ac

- Page 183 and 184:

Deep drawing and stretch drawing 3

- Page 185 and 186:

Deep drawing and stretch drawing 20

- Page 187 and 188:

Deep drawing and stretch drawing β

- Page 189 and 190:

Deep drawing and stretch drawing Ex

- Page 191 and 192:

Deep drawing and stretch drawing Bl

- Page 193 and 194:

Deep drawing and stretch drawing bl

- Page 195 and 196:

Deep drawing and stretch drawing Ta

- Page 197 and 198:

Deep drawing and stretch drawing Au

- Page 199 and 200:

Deep drawing and stretch drawing Ti

- Page 201 and 202:

Deep drawing and stretch drawing Hi

- Page 203 and 204:

Deep drawing and stretch drawing -

- Page 205 and 206:

Deep drawing and stretch drawing -

- Page 207 and 208:

Deep drawing and stretch drawing se

- Page 209 and 210:

Deep drawing and stretch drawing fo

- Page 211 and 212:

Deep drawing and stretch drawing pu

- Page 213 and 214:

Deep drawing and stretch drawing ag

- Page 215 and 216:

Coil lines Fig. 4.3.1 Coil line for

- Page 217 and 218:

Coil lines Fig. 4.3.3 Compact desig

- Page 219 and 220:

Sheet metal forming lines In the ca

- Page 221 and 222:

Sheet metal forming lines Fig. 4.4.

- Page 223 and 224:

Sheet metal forming lines ing of th

- Page 225 and 226:

Sheet metal forming lines (Fig. 4.4

- Page 227 and 228:

Sheet metal forming lines The two l

- Page 229 and 230:

Sheet metal forming lines 1,860mm a

- Page 231 and 232:

Sheet metal forming lines ver’s c

- Page 233 and 234:

Sheet metal forming lines Fig. 4.4.

- Page 235 and 236:

Sheet metal forming lines During th

- Page 237 and 238:

Sheet metal forming lines 4.4.4 Des

- Page 239 and 240:

Sheet metal forming lines Fig. 4.4.

- Page 241 and 242:

Sheet metal forming lines Fig. 4.4.

- Page 243 and 244:

Sheet metal forming lines individua

- Page 245 and 246:

Sheet metal forming lines As early

- Page 247 and 248:

Sheet metal forming lines In modern

- Page 249 and 250:

Sheet metal forming lines 4.4.6 Tra

- Page 251 and 252:

Sheet metal forming lines protects

- Page 253 and 254:

Sheet metal forming lines Within th

- Page 255 and 256:

Sheet metal forming lines power req

- Page 257 and 258:

Sheet metal forming lines Press lay

- Page 259 and 260:

Sheet metal forming lines higher st

- Page 261 and 262:

Sheet metal forming lines Draw cush

- Page 263 and 264:

Sheet metal forming lines These com

- Page 265 and 266:

Sheet metal forming lines motion cu

- Page 267 and 268:

Sheet metal forming lines increase

- Page 269 and 270:

Sheet metal forming lines (cf. Fig.

- Page 271 and 272:

Sheet metal forming lines larly str

- Page 273 and 274:

Sheet metal forming lines ing parts

- Page 275 and 276:

Sheet metal forming lines - efficie

- Page 277 and 278:

Sheet metal forming lines - Automat

- Page 279 and 280:

Sheet metal forming lines Local ope

- Page 281 and 282:

Sheet metal forming lines modules a

- Page 283 and 284:

Sheet metal forming lines Table 4.4

- Page 285 and 286:

Sheet metal forming lines Fig. 4.4.

- Page 287 and 288:

Sheet metal forming lines sion foll

- Page 289 and 290:

Blanking processes to complete brea

- Page 291 and 292:

Blanking processes Fig. 4.5.5 Top-t

- Page 293 and 294:

Blanking processes 56.8% 65.0% 67.4

- Page 295 and 296:

Blanking processes a configuration

- Page 297 and 298:

Blanking processes flat punch U bev

- Page 299 and 300:

Blanking processes Using these equa

- Page 301 and 302:

Blanking processes x S = 66. 6 (s a

- Page 303 and 304:

Blanking processes 0.18 10 10.36 27

- Page 305 and 306:

Shearing lines Fig. 4.6.1 Slitting

- Page 307 and 308:

Shearing lines The blanking process

- Page 309 and 310:

Shearing lines Blanking presses for

- Page 311 and 312:

Shearing lines 4.6.3 High-speed bla

- Page 313 and 314:

Shearing lines mass counterbalance

- Page 315 and 316:

Shearing lines Fig. 4.6.9 Influence

- Page 317 and 318:

Shearing lines Fig. 4.6.11 Rotor an

- Page 319 and 320:

Shearing lines Fig. 4.6.13 Complete

- Page 321 and 322:

Shearing lines Fig. 4.6.15 Complete

- Page 323 and 324:

Shearing lines Fig. 4.6.17 Flexible

- Page 325 and 326:

Shearing lines which run, backlash-

- Page 327 and 328:

Shearing lines that up to 150 strok

- Page 329 and 330:

Shearing lines Fig. 4.6.21 Automati

- Page 331 and 332:

Shearing lines Fig. 4.6.24 Passenge

- Page 333 and 334:

Shearing lines F F resistance weldi

- Page 335 and 336:

Shearing lines In contrast to conve

- Page 337 and 338:

Shearing lines The stripper plate i

- Page 339 and 340:

Shearing lines Fig. 4.6.32 Examples

- Page 341 and 342:

Shearing lines - provision of all i

- Page 343 and 344:

Shearing lines Fig. 4.6.35 Machine

- Page 345 and 346:

Shearing lines Fig. 4.6.37 Failure

- Page 347 and 348:

Shearing lines Structure of the ele

- Page 349 and 350:

Shearing lines interference, or whe

- Page 351 and 352:

Fine blanking - smaller dimensional

- Page 353 and 354:

Fine blanking f i blanking force F

- Page 355 and 356:

Fine blanking blanking force F s I

- Page 357 and 358:

Fine blanking plate of the die, whi

- Page 359 and 360:

Fine blanking case hardening nitrit

- Page 361 and 362:

Fine blanking not been soft anneale

- Page 363 and 364:

Fine blanking it is also possible t

- Page 365 and 366:

Fine blanking Example: We wish to p

- Page 367 and 368:

Fine blanking s h S1 tearing E frac

- Page 369 and 370:

Fine blanking punches, as well as t

- Page 371 and 372:

Fine blanking subsequently quenched

- Page 373 and 374:

Fine blanking Fig. 4.7.22 Two-stati

- Page 375 and 376:

Fine blanking Blanking plate 2 is l

- Page 377 and 378:

Fine blanking 1 2 5 6 3 Fig. 4.7.25

- Page 379 and 380:

Fine blanking blankingpunch 1 2 inn

- Page 381 and 382:

Fine blanking vee-ring piston diehe

- Page 383 and 384:

Fine blanking measuring the pressur

- Page 385 and 386:

Fine blanking pallets reach the sta

- Page 387 and 388:

Bending Table 4.8.1 gives the small

- Page 389 and 390:

Bending Accordingly, the necessary

- Page 391 and 392:

Bending Example: You wish to bend a

- Page 393 and 394:

Bending F F b or b 2 b ⋅s ⋅R =

- Page 395 and 396: Bending Fig. 4.8.7 Roll forming: ro

- Page 397 and 398: Bending Fig. 4.8.13 Hat sections Fi

- Page 399 and 400: Bending Table 4.8.3: Material coeff

- Page 401 and 402: Bending The roll stand for profile

- Page 403 and 404: Bending frame Fig. 4.8.23 Work shaf

- Page 405 and 406: Bending Fig. 4.8.25 Roller straight

- Page 407 and 408: Bending W W t t W Wma s Fig. 4.8.28

- Page 409 and 410: 4 Sheet metal forming and blanking

- Page 411 and 412: Organization of stamping plants Whe

- Page 413 and 414: Organization of stamping plants Tab

- Page 415 and 416: Organization of stamping plants lic

- Page 417 and 418: Organization of stamping plants bat

- Page 419 and 420: Organization of stamping plants Tab

- Page 421 and 422: Organization of stamping plants ele

- Page 423 and 424: Organization of stamping plants une

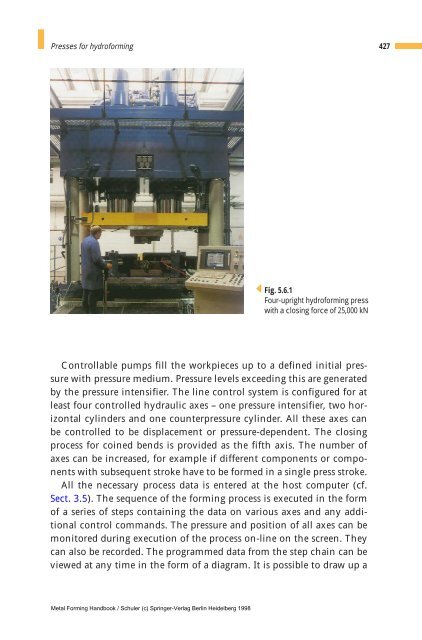

- Page 425 and 426: 5 Hydroforming 5.1 General One of t

- Page 427 and 428: Process technology and example appl

- Page 429 and 430: Process technology and example appl

- Page 431 and 432: Process technology and example appl

- Page 433 and 434: 5 Hydroforming 5.3 Component develo

- Page 435 and 436: Component development a component d

- Page 437 and 438: Component development 100% D D 75%

- Page 439 and 440: Component development Pure expansio

- Page 441 and 442: Die engineering diameter and stroke

- Page 443 and 444: 5 Hydroforming 5.5 Materials and pr

- Page 445: Materials and preforms for producin

- Page 449 and 450: 5 Hydroforming 5.7 General consider

- Page 451 and 452: General considerations inward hole

- Page 453 and 454: 6 Solid forming (Forging) 6.1 Gener

- Page 455 and 456: General lets that can be produced t

- Page 457 and 458: General Fig. 6.1.4 Examples of coin

- Page 459 and 460: General Table 6.1.1: Comparison bet

- Page 461 and 462: 6 Solid forming (Forging) 6.2 Benef

- Page 463 and 464: Benefits of solid forming 6.2.2 Wor

- Page 465 and 466: Benefits of solid forming range”

- Page 467 and 468: Benefits of solid forming sions fro

- Page 469 and 470: Benefits of solid forming Where no

- Page 471 and 472: Materials, billet production and su

- Page 473 and 474: Materials, billet production and su

- Page 475 and 476: Materials, billet production and su

- Page 477 and 478: Materials, billet production and su

- Page 479 and 480: Materials, billet production and su

- Page 481 and 482: Materials, billet production and su

- Page 483 and 484: Materials, billet production and su

- Page 485 and 486: Formed part and process plan requir

- Page 487 and 488: Formed part and process plan 6.4.2

- Page 489 and 490: 6 Solid forming (Forging) 6.5 Force

- Page 491 and 492: Force and work requirement d 0 d 2

- Page 493 and 494: Force and work requirement For die

- Page 495 and 496: Force and work requirement The mini

- Page 497 and 498:

Force and work requirement dies) (c

- Page 499 and 500:

Part transfer There is a broad rang

- Page 501 and 502:

Part transfer For cold forming proc

- Page 503 and 504:

Metal Forming Handbook / Schuler (c

- Page 505 and 506:

6 Solid forming (Forging) 6.7 Die d

- Page 507 and 508:

Die design wedge adjustment auxilia

- Page 509 and 510:

Die design Table 6.7.1: Modular sys

- Page 511 and 512:

Die design Fig. 6.7.5 Shearing die

- Page 513 and 514:

Die design for radial stress � r

- Page 515 and 516:

Die design The off-center applied f

- Page 517 and 518:

Die design Table 6.7.4: Heat treatm

- Page 519 and 520:

Die design Powder metal-manufacture

- Page 521 and 522:

Die design ledeburitic 12 % chromiu

- Page 523 and 524:

Die design system integrated into b

- Page 525 and 526:

6 Solid forming (Forging) 6.8 Press

- Page 527 and 528:

Presses used for solid forming mult

- Page 529 and 530:

Presses used for solid forming slid

- Page 531 and 532:

Presses used for solid forming Fig.

- Page 533 and 534:

Presses used for solid forming duct

- Page 535 and 536:

Presses used for solid forming Fig.

- Page 537 and 538:

Presses used for solid forming 6.8.

- Page 539 and 540:

Presses used for solid forming Fig.

- Page 541 and 542:

Presses used for solid forming tati

- Page 543 and 544:

Presses used for solid forming adeq

- Page 545 and 546:

Presses used for solid forming Embo

- Page 547 and 548:

Presses used for solid forming ment

- Page 549 and 550:

Presses used for solid forming feed

- Page 551 and 552:

Presses used for solid forming hopp

- Page 553 and 554:

Presses used for solid forming coin

- Page 555 and 556:

Presses used for solid forming Univ

- Page 557 and 558:

Presses used for solid forming Meda

- Page 559 and 560:

Presses used for solid forming CNC-

- Page 561 and 562:

Presses used for solid forming forc

- Page 563 and 564:

Index A.S.T.M.-standard 451 abrasio

- Page 565 and 566:

Index cylinder -, counterpressure 4

- Page 567 and 568:

Index flying shear 288 flywheel 51-

- Page 569 and 570:

Index modified top drive 205-207 mo

- Page 571 and 572:

Index sand blasting 460 sandwich co

- Page 573:

Index washing/cleaning machine 219