- Page 2 and 3:

Cinnamon and Cassia The genus Cinna

- Page 4 and 5:

Cinnamon and Cassia The genus Cinna

- Page 6:

This volume is dedicated to Prof. (

- Page 9 and 10:

viii Contents 10 Pests and diseases

- Page 11 and 12:

x Contributors Subhan C. Nath Regio

- Page 13 and 14:

xii Preface to the series compounds

- Page 15 and 16:

xiv Preface When we approached the

- Page 18 and 19:

1 Introduction P.N. Ravindran and K

- Page 20 and 21:

French Casse, Canefice, Canelle de

- Page 22 and 23:

Introduction 5 were accomplished sa

- Page 24 and 25:

Introduction 7 It seems quite proba

- Page 26 and 27:

Introduction 9 rose to 450,000 kg.

- Page 28 and 29:

Introduction 11 Sri Lanka has been

- Page 30 and 31:

Introduction 13 ISO (1977) Oil of c

- Page 32 and 33:

Botany and Crop Improvement of Cinn

- Page 34 and 35:

(a) (c) Botany and Crop Improvement

- Page 36 and 37:

Botany and Crop Improvement of Cinn

- Page 38 and 39:

Indian cassia leaves (known as ‘T

- Page 40 and 41:

Botany and Crop Improvement of Cinn

- Page 42 and 43:

Botany and Crop Improvement of Cinn

- Page 44 and 45:

Botany and Crop Improvement of Cinn

- Page 46 and 47:

1 2 Botany and Crop Improvement of

- Page 48 and 49:

Table 2.4 Stomatal characteristics

- Page 50 and 51:

1 3 4 Collenchyma Stone cell Phloem

- Page 52 and 53:

Botany and Crop Improvement of Cinn

- Page 54 and 55:

Table 2.6 Microscopic characteristi

- Page 56 and 57:

(k) Medullary 2 cells wide, radiall

- Page 58 and 59:

Botany and Crop Improvement of Cinn

- Page 60 and 61:

1 7 1a 7 Wood anatomy 4 6 2 2a Bota

- Page 62 and 63:

(a) (b) Morning Botany and Crop I

- Page 64 and 65:

1 2 3 4 6 8 9 Botany and Crop Impro

- Page 66 and 67:

Botany and Crop Improvement of Cinn

- Page 68 and 69:

Botany and Crop Improvement of Cinn

- Page 70 and 71:

Botany and Crop Improvement of Cinn

- Page 72 and 73:

Botany and Crop Improvement of Cinn

- Page 74 and 75:

Botany and Crop Improvement of Cinn

- Page 76 and 77:

Botany and Crop Improvement of Cinn

- Page 78 and 79:

viability is completely lost (Kanna

- Page 80 and 81:

Botany and Crop Improvement of Cinn

- Page 82 and 83:

Other tissue culture studies Botany

- Page 84 and 85:

Table 2.11 Bark and leaf oil consti

- Page 86 and 87:

Table 2.13 Growth and yield paramet

- Page 88 and 89:

Botany and Crop Improvement of Cinn

- Page 90 and 91:

Little crop improvement work has go

- Page 92 and 93:

Botany and Crop Improvement of Cinn

- Page 94 and 95:

Botany and Crop Improvement of Cinn

- Page 96 and 97:

Botany and Crop Improvement of Cinn

- Page 98 and 99:

Chemistry of Cinnamon and Cassia 81

- Page 100 and 101:

Chemistry of Cinnamon and Cassia 83

- Page 102 and 103:

Chemistry of Cinnamon and Cassia 85

- Page 104 and 105:

Table 3.4 Volatile constituents ide

- Page 106 and 107:

Chemistry of Cinnamon and Cassia 89

- Page 108 and 109:

Chemistry of Cinnamon and Cassia 91

- Page 110 and 111:

HO Chemistry of Cinnamon and Cassia

- Page 112 and 113:

Chemistry of Cinnamon and Cassia 95

- Page 114 and 115:

Chemistry of Cinnamon and Cassia 97

- Page 116 and 117:

-Humulene 1.30 0.57 0.12 1.40 -Cube

- Page 118 and 119:

1 3 2 4 4 5 7 6 8 10 9 12 11 13 14

- Page 120 and 121:

1147 Isoborneol 0.36 0.55 1158 Born

- Page 122 and 123:

Chemistry of Cinnamon and Cassia 10

- Page 124 and 125:

opportunities lies in the new centu

- Page 126 and 127:

R OH 4 HO O O O OH Chemistry of Cin

- Page 128 and 129:

Chemistry of Cinnamon and Cassia 11

- Page 130 and 131:

Chemistry of Cinnamon and Cassia 11

- Page 132 and 133:

p-Cymene 13 21.35 0.82 -Copaene 0.4

- Page 134 and 135:

(E)-cinnamyl acetate 0.1 0.2-2.2 -3

- Page 136 and 137:

Annex 3.3 The chemical structure of

- Page 138 and 139:

4 Cultivation and Management of Cin

- Page 140 and 141:

Figure 4.2 Field plantation of cinn

- Page 142 and 143:

the age of three to four months exc

- Page 144 and 145:

Cultivation and Management of Cinna

- Page 146 and 147:

Cultivation and Management of Cinna

- Page 148 and 149:

HARVESTED CINNAMON Cutting Extracti

- Page 150 and 151:

(a) (b) Figure 5.3 (a) Cinnamon pee

- Page 152 and 153:

Chips Harvesting, Processing, and Q

- Page 154 and 155:

cassia oils, is obtained from disti

- Page 156 and 157:

KETTLE FURNACE Harvesting, Processi

- Page 158 and 159:

the oleoresin is stored in suitable

- Page 160 and 161:

Grades The Cinnamon bark shall have

- Page 162 and 163:

Quality of Reagents Unless specifie

- Page 164 and 165:

Cinnamon powder Harvesting, Process

- Page 166 and 167:

Table 5A.5 Chemical requirements Ha

- Page 168 and 169:

Harvesting, Processing, and Quality

- Page 170 and 171:

Special protection information Resp

- Page 172 and 173:

Ash Refer to Annex 5.3. Acid insolu

- Page 174 and 175:

Chinese Cassia 157 Figure 6.1 Cinna

- Page 176 and 177:

Figure 6.2 A 15-year old plantation

- Page 178 and 179:

Chinese Cassia 161 careful harrowin

- Page 180 and 181:

make it easier to climb and to avoi

- Page 182 and 183:

Adulterations and substitutes In ea

- Page 184 and 185: Chinese Cassia 167 various regions

- Page 186 and 187: Table 6.4 Insect pests of cassia ci

- Page 188 and 189: Chinese Cassia 171 Table 6.5 Compos

- Page 190 and 191: Trace Methyl eugenol Trace Benzoic

- Page 192 and 193: Table 6.9 Comparative percentages,

- Page 194 and 195: Chinese Cassia 177 (3-5°C) or due

- Page 196 and 197: Chinese Cassia 179 curing diseases

- Page 198 and 199: Chinese Cassia 181 different parts

- Page 200 and 201: Chinese Cassia 183 Kashiwada, Y., N

- Page 202 and 203: 7 Indonesian Cassia (Indonesian Cin

- Page 204 and 205: propagation is possible through cut

- Page 206 and 207: Indonesian Cassia (Indonesian Cinna

- Page 208 and 209: Figure 7.3 Separation of bark by be

- Page 210 and 211: the branch. The mycelium layer pene

- Page 212 and 213: Table 7.4 The yield and characteris

- Page 214 and 215: Conclusion In spite of the fact tha

- Page 216 and 217: 8 Indian Cassia Akhil Baruah and Su

- Page 218 and 219: Indian Cassia 201 pollen dehiscence

- Page 220 and 221: Indian Cassia 203 Ecology and distr

- Page 222 and 223: Table 8.1 Physico-chemical characte

- Page 224 and 225: Indian Cassia 207 Table 8.4 Composi

- Page 226 and 227: References Indian Cassia 209 Anonym

- Page 228 and 229: 9 Camphor Tree K. Nirmal Babu, P.N.

- Page 230 and 231: Sub-specific division of C. camphor

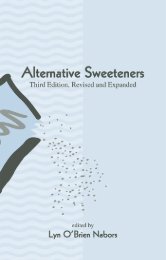

- Page 232 and 233: Camphor Tree 215 succession species

- Page 236 and 237: Table 9.1 Relation between age of t

- Page 238 and 239: Table 9.3 Yield of camphor and oil

- Page 240 and 241: Camphor Tree 223 Yu-Sho oil: Specif

- Page 242 and 243: Ketones and oxides: Camphor, piperi

- Page 244 and 245: Camphor Tree 227 20 Citronellyl ace

- Page 246 and 247: Table 9.12 Chemical composition (%)

- Page 248 and 249: Camphor Tree 231 Table 9.14 Yield a

- Page 250 and 251: Camphor Tree 233 Table 9.18 Physico

- Page 252 and 253: Camphor Tree 235 To prevent bed-sor

- Page 254 and 255: Camphor Tree 237 Chopra, R.N., Chop

- Page 256 and 257: 10 Pests and Diseases of Cinnamon a

- Page 258 and 259: Family: Dermestidae Evorinea hirtel

- Page 260 and 261: Pests and Diseases of Cinnamon and

- Page 262 and 263: Pests and Diseases of Cinnamon and

- Page 264 and 265: Leaf webber (Orthaga vitalis) Pests

- Page 266 and 267: C. malabatrum Meliola beilschmiedia

- Page 268 and 269: Pests and Diseases of Cinnamon and

- Page 270 and 271: Pests and Diseases of Cinnamon and

- Page 272 and 273: Pests and Diseases of Cinnamon and

- Page 274 and 275: Pests and Diseases of Cinnamon and

- Page 276 and 277: 11 Pharmacology and Toxicology of C

- Page 278 and 279: Anti-inflammatory action Pharmacolo

- Page 280 and 281: Pharmacology and Toxicology of Cinn

- Page 282 and 283: Pharmacology and Toxicology of Cinn

- Page 284 and 285:

Pharmacology and Toxicology of Cinn

- Page 286 and 287:

Table 11.1 Antibacterial effects of

- Page 288 and 289:

Pharmacology and Toxicology of Cinn

- Page 290 and 291:

Table 11.2 Antifungal activity of c

- Page 292 and 293:

Pharmacology and Toxicology of Cinn

- Page 294 and 295:

Pharmacology and Toxicology of Cinn

- Page 296 and 297:

Pharmacology and Toxicology of Cinn

- Page 298 and 299:

Pharmacology and Toxicology of Cinn

- Page 300 and 301:

Pharmacology and Toxicology of Cinn

- Page 302 and 303:

12 Economics and Marketing of Cinna

- Page 304 and 305:

Economics and Marketing of Cinnamon

- Page 306 and 307:

Economics and Marketing of Cinnamon

- Page 308 and 309:

Economics and Marketing of Cinnamon

- Page 310 and 311:

Table 12.7 US imports of whole cass

- Page 312 and 313:

Japan Economics and Marketing of Ci

- Page 314 and 315:

Economics and Marketing of Cinnamon

- Page 316 and 317:

Table 12.14 US exports of cassia an

- Page 318 and 319:

Table 12.16 World exports of cinnam

- Page 320 and 321:

Economics and Marketing of Cinnamon

- Page 322 and 323:

Table 12.20 US imports of cassia oi

- Page 324 and 325:

Economics and Marketing of Cinnamon

- Page 326 and 327:

S t 0.37Y t 0.63S t1 Economics an

- Page 328 and 329:

13 End Uses of Cinnamon and Cassia

- Page 330 and 331:

Table 13.3 Typical western pickling

- Page 332 and 333:

End Uses of Cinnamon and Cassia 315

- Page 334 and 335:

Table 13.9 Relative flavour intensi

- Page 336 and 337:

Cinnamon - in perfumes and beauty c

- Page 338 and 339:

End Uses of Cinnamon and Cassia 321

- Page 340 and 341:

Chinese Cassia Chinese cassia - as

- Page 342 and 343:

End Uses of Cinnamon and Cassia 325

- Page 344 and 345:

14 Cinnamon and Cassia - The Future

- Page 346 and 347:

Cinnamon and Cassia - The Future Vi

- Page 348 and 349:

Table 15.1 Chemical composition of

- Page 350 and 351:

Table 15.3 Constituents of leaf oil

- Page 352 and 353:

cloves. Leaves measure 3-12 1.5-4

- Page 354 and 355:

C. deschampsii Gamble C. deschampsi

- Page 356 and 357:

Table 15.7 Composition of essential

- Page 358 and 359:

Other Useful Species of Cinnamomum

- Page 360 and 361:

Table 15.9 Compounds identified in

- Page 362 and 363:

C. sulphuratum Nees Other Useful Sp

- Page 364 and 365:

Table 15.13 Percentage composition

- Page 366 and 367:

Other Useful Species of Cinnamomum

- Page 368 and 369:

Other Useful Species of Cinnamomum

- Page 370 and 371:

Other Useful Species of Cinnamomum

- Page 372 and 373:

Other Useful Species of Cinnamomum

- Page 374 and 375:

location 90 physico-chemical proper

- Page 376 and 377:

mass spectrometric studies 97 extra

- Page 378 and 379:

metabolic studies 267 sedative effe