1948-1952 Shop Service Manual - - Hudson-Essex-Terraplane Club

1948-1952 Shop Service Manual - - Hudson-Essex-Terraplane Club

1948-1952 Shop Service Manual - - Hudson-Essex-Terraplane Club

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6 - 26 ELECTRICAL SYSTEM<br />

7. Turn the condenser switch to the " Micro-farad". The<br />

meter should read 20 to 25 microfarads for both six and<br />

eight cylinder engines.<br />

8. Turn the condenser switch to the "Meg-ohm" position.<br />

Meter should now read in the blue bar at left side<br />

marked "MEG" for satisfactory condenser insulation.<br />

If the meter reads in the red bar or over to the extreme<br />

right, replace the condenser.<br />

NOTE: When making the above checks, the condenser<br />

should be at operating temperatures.<br />

COIL<br />

The ignition coil used is Auto-Lite CR-6012-A; the coil<br />

provides a means of stepping up the six volt primary current<br />

to high voltage necessary to jump the spark plug gap. The<br />

primary winding of the coil is connected to the battery<br />

through the distributor contact points. The secondary winding<br />

of the coil is connected to the spark plug through the<br />

rotor and distributor cap.<br />

COIL TEST:<br />

1. Calibrate Coil Breaker Unit.<br />

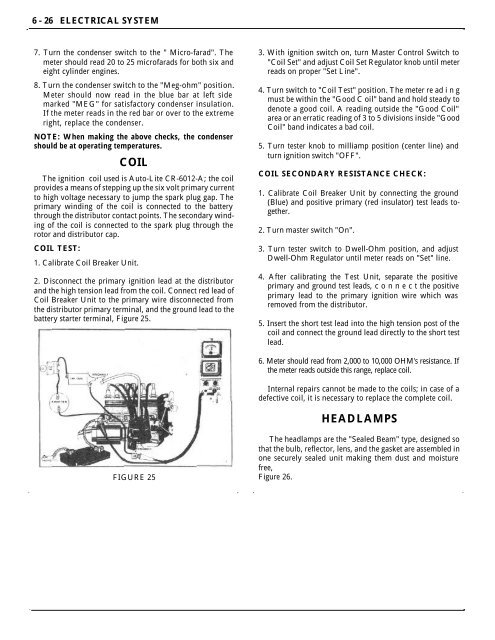

2. Disconnect the primary ignition lead at the distributor<br />

and the high tension lead from the coil. Connect red lead of<br />

Coil Breaker Unit to the primary wire disconnected from<br />

the distributor primary terminal, and the ground lead to the<br />

battery starter terminal, Figure 25.<br />

3. With ignition switch on, turn Master Control Switch to<br />

"Coil Set" and adjust Coil Set Regulator knob until meter<br />

reads on proper "Set Line".<br />

4. Turn switch to "Coil Test" position. The meter re ad i n g<br />

must be within the "Good C oil" band and hold steady to<br />

denote a good coil. A reading outside the "Good Coil"<br />

area or an erratic reading of 3 to 5 divisions inside "Good<br />

Coil" band indicates a bad coil.<br />

5. Turn tester knob to milliamp position (center line) and<br />

turn ignition switch "OFF".<br />

COIL SECONDARY RESISTANCE CHECK:<br />

1. Calibrate Coil Breaker Unit by connecting the ground<br />

(Blue) and positive primary (red insulator) test leads together.<br />

2. Turn master switch "On".<br />

3. Turn tester switch to Dwell-Ohm position, and adjust<br />

Dwell-Ohm Regulator until meter reads on "Set" line.<br />

4. After calibrating the Test Unit, separate the positive<br />

primary and ground test leads, c o n n e c t the positive<br />

primary lead to the primary ignition wire which was<br />

removed from the distributor.<br />

5. Insert the short test lead into the high tension post of the<br />

coil and connect the ground lead directly to the short test<br />

lead.<br />

6. Meter should read from 2,000 to 10,000 OHM's resistance. If<br />

the meter reads outside this range, replace coil.<br />

Internal repairs cannot be made to the coils; in case of a<br />

defective coil, it is necessary to replace the complete coil.<br />

HEADLAMPS<br />

FIGURE 25<br />

The headlamps are the "Sealed Beam" type, designed so<br />

that the bulb, reflector, lens, and the gasket are assembled in<br />

one securely sealed unit making them dust and moisture<br />

free,<br />

Figure 26.