vero uk training material - VCAM TECH Co., Ltd

vero uk training material - VCAM TECH Co., Ltd

vero uk training material - VCAM TECH Co., Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

VISI Mould - Slide Assembly Creation<br />

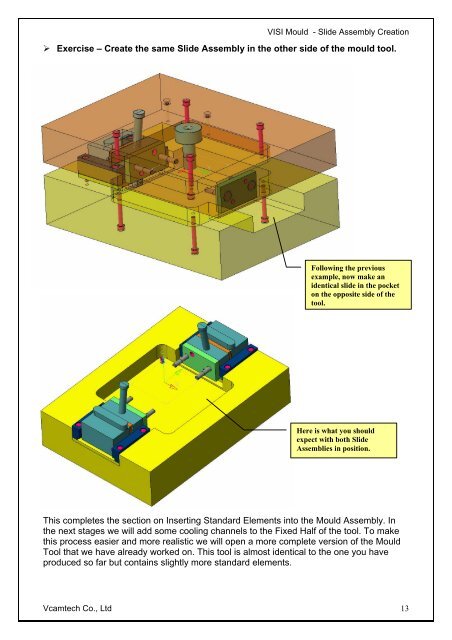

Exercise – Create the same Slide Assembly in the other side of the mould tool.<br />

Following the previous<br />

example, now make an<br />

identical slide in the pocket<br />

on the opposite side of the<br />

tool.<br />

Here is what you should<br />

expect with both Slide<br />

Assemblies in position.<br />

This completes the section on Inserting Standard Elements into the Mould Assembly. In<br />

the next stages we will add some cooling channels to the Fixed Half of the tool. To make<br />

this process easier and more realistic we will open a more complete version of the Mould<br />

Tool that we have already worked on. This tool is almost identical to the one you have<br />

produced so far but contains slightly more standard elements.<br />

Vcamtech <strong>Co</strong>., <strong>Ltd</strong> 13