vero uk training material - VCAM TECH Co., Ltd

vero uk training material - VCAM TECH Co., Ltd

vero uk training material - VCAM TECH Co., Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

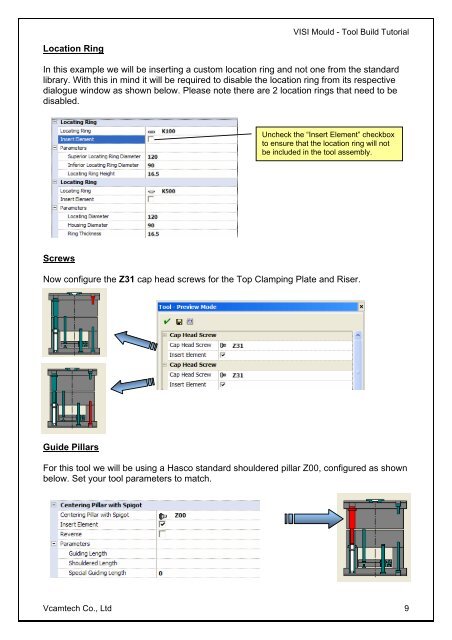

Location Ring<br />

VISI Mould - Tool Build Tutorial<br />

In this example we will be inserting a custom location ring and not one from the standard<br />

library. With this in mind it will be required to disable the location ring from its respective<br />

dialogue window as shown below. Please note there are 2 location rings that need to be<br />

disabled.<br />

Screws<br />

Now configure the Z31 cap head screws for the Top Clamping Plate and Riser.<br />

Guide Pillars<br />

Uncheck the “Insert Element” checkbox<br />

to ensure that the location ring will not<br />

be included in the tool assembly.<br />

For this tool we will be using a Hasco standard shouldered pillar Z00, configured as shown<br />

below. Set your tool parameters to match.<br />

Vcamtech <strong>Co</strong>., <strong>Ltd</strong> 9