The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iatemperature (70 degrees Celsius minus 10 degreesCelsius).Table 2: Results according to EN 15632 at a temperaturedifference of 60 Kelvin.Product Type Heat LossBuriedsystemW/mΛ System(W/m.K)ST/PUR 90DN25 11.6 0.042ST/PUR 160DN80 16.0 0.033PEX/PUR 162A110 22.3 0.049PB/PE 63A32 15.2 0.038PB/PE 90A32 12.8 0.044PB/PE 125A63 22.0 0.056PB/PE 200A110 27.4 0.068PEX/PE II 90A32 16.6 0.057PEX/PE II 160A63 17.6 0.055PEX/PE II 200A110 31.1 0.073PEX/PE I 140A32 12.5 0.057PEX/PE I 175A63 17.6 0.059PEX/PE I 200A110 28.8 0.051COMPARISON OF FLEXIBLE PLASTICPRE-INSULATED PIPESThis chapter compares the flexible pre-insulated pipes.The comparis<strong>on</strong> is based <strong>on</strong> three diametersrepresenting the entire diameter range for plastic preinsulatedpipes.The comparis<strong>on</strong> is exp<strong>and</strong>ed by evaluating the heatloss in correlati<strong>on</strong> to the outer casing diameter (resp.the foam area).In Table 1 the flexible plastic pre-insulated pipes aredefined. These are the products PEX/PEX, PEX/PUR<strong>and</strong> PB/PE.For more informati<strong>on</strong> c<strong>on</strong>cerning the PB/PE preinsulatedpipes see „Heat loss of flexible plastic pipesystems, analysis <strong>and</strong> optimizati<strong>on</strong>‟ by van der Ven etal. [4].The 32, 63 <strong>and</strong> 110 millimetre service pipesFirst the absolute heat loss is displayed, followed bythe insulati<strong>on</strong> area analysis.Absolute heat lossIn this paragraph all absolute heat loss values arecompared for the 32, 63 <strong>and</strong> 110 millimetre servicepipes.In Graph 1 the results are displayed for temperaturedifference of 60 Kelvin.Heat Loss [W/m]35.030.025.020.015.010.05.00.0PB/PE PEX/PEX I PEX/PEX II PEX/PUR90/32 160/63 200/110Diameter service pipe [mm]Graph 1 Absolute Heat Loss 32, 63 <strong>and</strong> 110 mm servicepipe (dT = 60 K)The products based <strong>on</strong> PE or PE-x foam show higherheat losses for the 110 mm service pipe than thesystem based <strong>on</strong> PUR foam. The difference isapproximately 20 percent.The different test samples show a wide variance in thediameter of the outer casing.Therefore, <strong>on</strong>ly the results for the 32 millimetre servicepipe are comparable for PB/PE 90A32 <strong>and</strong> PEX/PEX II90A32. For the 110 mm service pipe, a comparis<strong>on</strong> canbe made between the PEX/PUR 200A110, PB/PE200A110, PEX/PEX II 200A110 <strong>and</strong> PEX/PEX I200A110.Another difference in this comparis<strong>on</strong> is the use of aPB pipe or a PE-x pipe. PB <strong>and</strong> PE-x have differentthermal c<strong>on</strong>ductivities (0.19 W/m.K versus 0.40W/m.K). However, this effect is already corrected byusing the Wallentén equati<strong>on</strong> [5], as shown in (1).Insulati<strong>on</strong> areaTo compare the different kinds of flexible pre-insulatedpipes <strong>on</strong> their performance, all outer diameters arealtered towards 90, 160 <strong>and</strong> 200 millimetres. The123

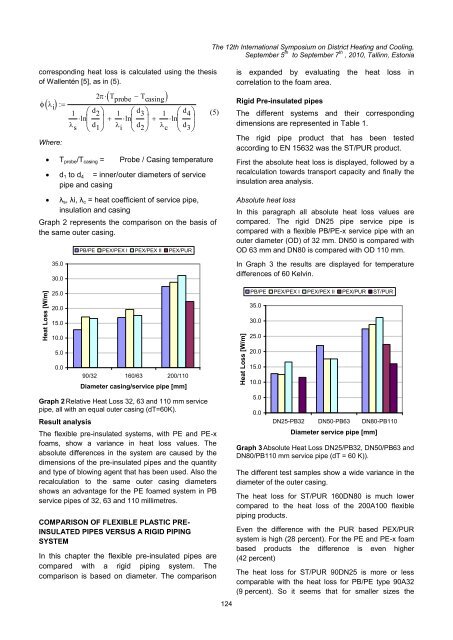

The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iacorresp<strong>on</strong>ding heat loss is calculated using the thesisof Wallentén [5], as in (5). i Where:1ln sd 2d 1 2 T probe T casing1 ln id 3d 21 ln c T probe /T casing = Probe / Casing temperature d 1 to d 4 = inner/outer diameters of servicepipe <strong>and</strong> casingd 4d 3λ s , λi, λ c = heat coefficient of service pipe,insulati<strong>on</strong> <strong>and</strong> casingGraph 2 represents the comparis<strong>on</strong> <strong>on</strong> the basis ofthe same outer casing.35.030.0PB/PE PEX/PEX I PEX/PEX II PEX/PUR(5)is exp<strong>and</strong>ed by evaluating the heat loss incorrelati<strong>on</strong> to the foam area.Rigid Pre-insulated pipesThe different systems <strong>and</strong> their corresp<strong>on</strong>dingdimensi<strong>on</strong>s are represented in Table 1.The rigid pipe product that has been testedaccording to EN 15632 was the ST/PUR product.First the absolute heat loss is displayed, followed by arecalculati<strong>on</strong> towards transport capacity <strong>and</strong> finally theinsulati<strong>on</strong> area analysis.Absolute heat lossIn this paragraph all absolute heat loss values arecompared. The rigid DN25 pipe service pipe iscompared with a flexible PB/PE-x service pipe with anouter diameter (OD) of 32 mm. DN50 is compared withOD 63 mm <strong>and</strong> DN80 is compared with OD 110 mm.In Graph 3 the results are displayed for temperaturedifferences of 60 Kelvin.Heat Loss [W/m]25.020.015.010.05.00.090/32 160/63 200/110Diameter casing/service pipe [mm]Graph 2 Relative Heat Loss 32, 63 <strong>and</strong> 110 mm servicepipe, all with an equal outer casing (dT=60K).Result analysisThe flexible pre-insulated systems, with PE <strong>and</strong> PE-xfoams, show a variance in heat loss values. Theabsolute differences in the system are caused by thedimensi<strong>on</strong>s of the pre-insulated pipes <strong>and</strong> the quantity<strong>and</strong> type of blowing agent that has been used. Also therecalculati<strong>on</strong> to the same outer casing diametersshows an advantage for the PE foamed system in PBservice pipes of 32, 63 <strong>and</strong> 110 millimetres.COMPARISON OF FLEXIBLE PLASTIC PRE-INSULATED PIPES VERSUS A RIGID PIPINGSYSTEMIn this chapter the flexible pre-insulated pipes arecompared with a rigid piping system. Thecomparis<strong>on</strong> is based <strong>on</strong> diameter. The comparis<strong>on</strong>124Heat Loss [W/m]PB/PE PEX/PEX I PEX/PEX II PEX/PUR ST/PUR35.030.025.020.015.010.05.00.0DN25-PB32 DN50-PB63 DN80-PB110Diameter service pipe [mm]Graph 3 Absolute Heat Loss DN25/PB32, DN50/PB63 <strong>and</strong>DN80/PB110 mm service pipe (dT = 60 K)).The different test samples show a wide variance in thediameter of the outer casing.The heat loss for ST/PUR 160DN80 is much lowercompared to the heat loss of the 200A100 flexiblepiping products.Even the difference with the PUR based PEX/PURsystem is high (28 percent). For the PE <strong>and</strong> PE-x foambased products the difference is even higher(42 percent)The heat loss for ST/PUR 90DN25 is more or lesscomparable with the heat loss for PB/PE type 90A32(9 percent). So it seems that for smaller sizes the

- Page 1:

12th Inter

- Page 5 and 6:

The 12th I

- Page 7 and 8:

The 12th I

- Page 10 and 11:

The 12th I

- Page 12 and 13:

The 12th I

- Page 14 and 15:

For the case of parallel buried pip

- Page 16 and 17:

The 12th I

- Page 18 and 19:

The 12th I

- Page 20 and 21:

The 12th I

- Page 22 and 23:

The 12th I

- Page 24 and 25:

The 12th I

- Page 26 and 27:

The 12th I

- Page 28 and 29:

The 12th I

- Page 30 and 31:

The 12th I

- Page 32 and 33:

The 12th I

- Page 34 and 35:

The 12th I

- Page 36 and 37:

The 12th I

- Page 38 and 39:

The 12th I

- Page 40 and 41:

The 12th I

- Page 42 and 43:

The 12th I

- Page 44 and 45:

The 12th I

- Page 46 and 47:

The 12th I

- Page 48 and 49:

The 12th I

- Page 50 and 51:

The 12th I

- Page 52 and 53:

The 12th I

- Page 54 and 55:

The 12th I

- Page 56 and 57:

The 12th I

- Page 58 and 59:

The 12th I

- Page 60 and 61:

The 12th I

- Page 62 and 63:

The 12th I

- Page 64 and 65:

The 12th I

- Page 66 and 67:

The 12th I

- Page 68 and 69:

The 12th I

- Page 70 and 71:

The 12th I

- Page 72 and 73:

The 12th I

- Page 74 and 75: The 12th I

- Page 76 and 77: The 12th I

- Page 78 and 79: The 12th I

- Page 80 and 81: The 12th I

- Page 82 and 83: The 12th I

- Page 84 and 85: The 12th I

- Page 86 and 87: The 12th I

- Page 88 and 89: The 12th I

- Page 90 and 91: The 12th I

- Page 92 and 93: The 12th I

- Page 94 and 95: The 12th I

- Page 96 and 97: The 12th I

- Page 98 and 99: the street the more shallow the sha

- Page 100 and 101: The 12th I

- Page 102 and 103: The 12th I

- Page 104 and 105: The 12th I

- Page 106 and 107: The 12th I

- Page 108 and 109: The 12th I

- Page 110 and 111: P-1P-4P-9P-7E-5P-14P-8The 1

- Page 112 and 113: The 12th I

- Page 114 and 115: The 12th I

- Page 116 and 117: The 12th I

- Page 118 and 119: The 12th I

- Page 120 and 121: The 12th I

- Page 122 and 123: The 12th I

- Page 126 and 127: The 12th I

- Page 128 and 129: The 12th I

- Page 130 and 131: The 12th I

- Page 132 and 133: The 12th I

- Page 134 and 135: The 12th I

- Page 136 and 137: The 12th I

- Page 138 and 139: to heating costs of 14,5 ct/kWh. Th

- Page 140 and 141: The 12th I

- Page 142 and 143: The 12th I

- Page 144 and 145: The 12th I

- Page 146 and 147: The 12th I

- Page 148 and 149: academic access is facilitated as t

- Page 150 and 151: The 12th I

- Page 152 and 153: The 12th I

- Page 154 and 155: The 12th I

- Page 156 and 157: The 12th I

- Page 158 and 159: The 12th I

- Page 160 and 161: The 12th I

- Page 162 and 163: 1. CHP system operation in A2. Ther

- Page 164 and 165: The 12th I

- Page 166 and 167: is covered by operating HOB. In oth

- Page 168 and 169: The 12th I

- Page 170 and 171: The 12th I

- Page 172 and 173: The 12th I

- Page 174 and 175:

The 12th I

- Page 176 and 177:

The 12th I

- Page 178 and 179:

The 12th I

- Page 180 and 181:

The 12th I

- Page 182 and 183:

The 12th I

- Page 184 and 185:

The 12th I

- Page 186 and 187:

The 12th I

- Page 188 and 189:

The 12th I

- Page 190 and 191:

The 12th I

- Page 192 and 193:

The 12th I

- Page 194 and 195:

The 12th I

- Page 196 and 197:

produce heat and electricity. Fluct

- Page 198 and 199:

The 12th I

- Page 200 and 201:

The 12th I

- Page 202 and 203:

The 12th I

- Page 204 and 205:

The 12th I

- Page 206 and 207:

The 12th I

- Page 208 and 209:

The 12th I

- Page 210 and 211:

To assure that the temperatures mea

- Page 212 and 213:

The 12th I

- Page 214 and 215:

The 12th I

- Page 216 and 217:

The 12th I

- Page 218 and 219:

The 12th I

- Page 220 and 221:

production and provide for marginal

- Page 222 and 223:

The 12th I

- Page 224 and 225:

The 12th I

- Page 226 and 227:

The 12th I

- Page 228 and 229:

The 12th I

- Page 230 and 231:

The 12th I

- Page 232 and 233:

The 12th I

- Page 234 and 235:

The 12th I

- Page 236 and 237:

The 12th I

- Page 238 and 239:

The 12th I

- Page 240 and 241:

The 12th I

- Page 242 and 243:

In addition, it can also be observe

- Page 244 and 245:

The 12th I

- Page 246 and 247:

owner is normally only interested i

- Page 248 and 249:

The 12th I

- Page 250 and 251:

The 12th I

- Page 252 and 253:

The 12th I

- Page 254 and 255:

The 12th I

- Page 256 and 257:

The 12th I

- Page 258 and 259:

The 12th I

- Page 260 and 261:

The 12th I

- Page 262 and 263:

The 12th I

- Page 264 and 265:

The 12th I

- Page 266 and 267:

The 12th I

- Page 268 and 269:

The 12th I

- Page 270 and 271:

The 12th I

- Page 272 and 273:

The 12th I

- Page 274 and 275:

The 12th I

- Page 276 and 277:

The 12th I

- Page 278 and 279:

The 12th I

- Page 280 and 281:

The 12th I

- Page 282 and 283:

The 12th I

- Page 284 and 285:

The 12th I

- Page 286 and 287:

The 12th I

- Page 288 and 289:

The 12th I

- Page 290 and 291:

Stockholm district heating system a

- Page 292 and 293:

The 12th I

- Page 294 and 295:

The 12th I

- Page 296 and 297:

The 12th I

- Page 298 and 299:

The 12th I

- Page 300 and 301:

The 12th I

- Page 302 and 303:

The 12th I

- Page 304 and 305:

The 12th I

- Page 306 and 307:

The 12th I

- Page 308 and 309:

The 12th I

- Page 310 and 311:

The 12th I

- Page 312 and 313:

The 12th I

- Page 314 and 315:

The values presented do of course l

- Page 316 and 317:

The 12th I

- Page 318 and 319:

The 12th I

- Page 320 and 321:

The 12th I

- Page 322 and 323:

The 12th I

- Page 324 and 325:

The 12th I

- Page 326:

The 12th I