12th International Symposium on District Heating and Cooling

12th International Symposium on District Heating and Cooling

12th International Symposium on District Heating and Cooling

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

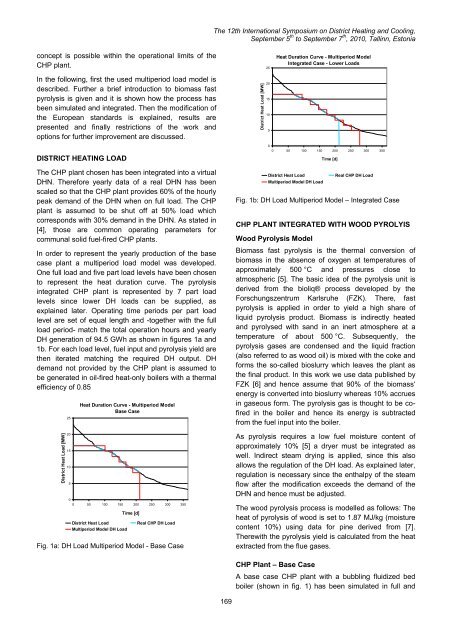

The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iac<strong>on</strong>cept is possible within the operati<strong>on</strong>al limits of theCHP plant.In the following, first the used multiperiod load model isdescribed. Further a brief introducti<strong>on</strong> to biomass fastpyrolysis is given <strong>and</strong> it is shown how the process hasbeen simulated <strong>and</strong> integrated. Then the modificati<strong>on</strong> ofthe European st<strong>and</strong>ards is explained, results arepresented <strong>and</strong> finally restricti<strong>on</strong>s of the work <strong>and</strong>opti<strong>on</strong>s for further improvement are discussed.<strong>District</strong> Heat Load [MW]252015105Heat Durati<strong>on</strong> Curve - Multiperiod ModelIntegrated Case - Lower LoadsDISTRICT HEATING LOADThe CHP plant chosen has been integrated into a virtualDHN. Therefore yearly data of a real DHN has beenscaled so that the CHP plant provides 60% of the hourlypeak dem<strong>and</strong> of the DHN when <strong>on</strong> full load. The CHPplant is assumed to be shut off at 50% load whichcorresp<strong>on</strong>ds with 30% dem<strong>and</strong> in the DHN. As stated in[4], those are comm<strong>on</strong> operating parameters forcommunal solid fuel-fired CHP plants.In order to represent the yearly producti<strong>on</strong> of the basecase plant a multiperiod load model was developed.One full load <strong>and</strong> five part load levels have been chosento represent the heat durati<strong>on</strong> curve. The pyrolysisintegrated CHP plant is represented by 7 part loadlevels since lower DH loads can be supplied, asexplained later. Operating time periods per part loadlevel are set of equal length <strong>and</strong> -together with the fullload period- match the total operati<strong>on</strong> hours <strong>and</strong> yearlyDH generati<strong>on</strong> of 94.5 GWh as shown in figures 1a <strong>and</strong>1b. For each load level, fuel input <strong>and</strong> pyrolysis yield arethen iterated matching the required DH output. DHdem<strong>and</strong> not provided by the CHP plant is assumed tobe generated in oil-fired heat-<strong>on</strong>ly boilers with a thermalefficiency of 0.85<strong>District</strong> Heat Load [MW]252015105Heat Durati<strong>on</strong> Curve - Multiperiod ModelBase Case00 50 100 150 200 250 300 350<strong>District</strong> Heat LoadMultiperiod Model DH LoadTime [d]Real CHP DH LoadFig. 1a: DH Load Multiperiod Model - Base Case00 50 100 150 200 250 300 350<strong>District</strong> Heat LoadMultiperiod Model DH LoadTime [d]Real CHP DH LoadFig. 1b: DH Load Multiperiod Model – Integrated CaseCHP PLANT INTEGRATED WITH WOOD PYROLYISWood Pyrolysis ModelBiomass fast pyrolysis is the thermal c<strong>on</strong>versi<strong>on</strong> ofbiomass in the absence of oxygen at temperatures ofapproximately 500 °C <strong>and</strong> pressures close toatmospheric [5]. The basic idea of the pyrolysis unit isderived from the bioliq® process developed by theForschungszentrum Karlsruhe (FZK). There, fastpyrolysis is applied in order to yield a high share ofliquid pyrolysis product. Biomass is indirectly heated<strong>and</strong> pyrolysed with s<strong>and</strong> in an inert atmosphere at atemperature of about 500 °C. Subsequently, thepyrolysis gases are c<strong>on</strong>densed <strong>and</strong> the liquid fracti<strong>on</strong>(also referred to as wood oil) is mixed with the coke <strong>and</strong>forms the so-called bioslurry which leaves the plant asthe final product. In this work we use data published byFZK [6] <strong>and</strong> hence assume that 90% of the biomass‘energy is c<strong>on</strong>verted into bioslurry whereas 10% accruesin gaseous form. The pyrolysis gas is thought to be cofiredin the boiler <strong>and</strong> hence its energy is subtractedfrom the fuel input into the boiler.As pyrolysis requires a low fuel moisture c<strong>on</strong>tent ofapproximately 10% [5] a dryer must be integrated aswell. Indirect steam drying is applied, since this alsoallows the regulati<strong>on</strong> of the DH load. As explained later,regulati<strong>on</strong> is necessary since the enthalpy of the steamflow after the modificati<strong>on</strong> exceeds the dem<strong>and</strong> of theDHN <strong>and</strong> hence must be adjusted.The wood pyrolysis process is modelled as follows: Theheat of pyrolysis of wood is set to 1.87 MJ/kg (moisturec<strong>on</strong>tent 10%) using data for pine derived from [7].Therewith the pyrolysis yield is calculated from the heatextracted from the flue gases.CHP Plant – Base CaseA base case CHP plant with a bubbling fluidized bedboiler (shown in fig. 1) has been simulated in full <strong>and</strong>169