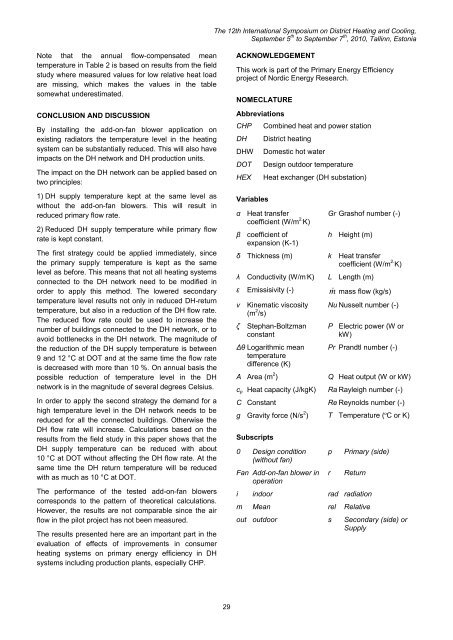

The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iaNote that the annual flow-compensated meantemperature in Table 2 is based <strong>on</strong> results from the fieldstudy where measured values for low relative heat loadare missing, which makes the values in the tablesomewhat underestimated.CONCLUSION AND DISCUSSIONBy installing the add-<strong>on</strong>-fan blower applicati<strong>on</strong> <strong>on</strong>existing radiators the temperature level in the heatingsystem can be substantially reduced. This will also haveimpacts <strong>on</strong> the DH network <strong>and</strong> DH producti<strong>on</strong> units.The impact <strong>on</strong> the DH network can be applied based <strong>on</strong>two principles:1) DH supply temperature kept at the same level aswithout the add-<strong>on</strong>-fan blowers. This will result inreduced primary flow rate.2) Reduced DH supply temperature while primary flowrate is kept c<strong>on</strong>stant.The first strategy could be applied immediately, sincethe primary supply temperature is kept as the samelevel as before. This means that not all heating systemsc<strong>on</strong>nected to the DH network need to be modified inorder to apply this method. The lowered sec<strong>on</strong>darytemperature level results not <strong>on</strong>ly in reduced DH-returntemperature, but also in a reducti<strong>on</strong> of the DH flow rate.The reduced flow rate could be used to increase thenumber of buildings c<strong>on</strong>nected to the DH network, or toavoid bottlenecks in the DH network. The magnitude ofthe reducti<strong>on</strong> of the DH supply temperature is between9 <strong>and</strong> 12 °C at DOT <strong>and</strong> at the same time the flow rateis decreased with more than 10 %. On annual basis thepossible reducti<strong>on</strong> of temperature level in the DHnetwork is in the magnitude of several degrees Celsius.In order to apply the sec<strong>on</strong>d strategy the dem<strong>and</strong> for ahigh temperature level in the DH network needs to bereduced for all the c<strong>on</strong>nected buildings. Otherwise theDH flow rate will increase. Calculati<strong>on</strong>s based <strong>on</strong> theresults from the field study in this paper shows that theDH supply temperature can be reduced with about10 °C at DOT without affecting the DH flow rate. At thesame time the DH return temperature will be reducedwith as much as 10 °C at DOT.The performance of the tested add-<strong>on</strong>-fan blowerscorresp<strong>on</strong>ds to the pattern of theoretical calculati<strong>on</strong>s.However, the results are not comparable since the airflow in the pilot project has not been measured.The results presented here are an important part in theevaluati<strong>on</strong> of effects of improvements in c<strong>on</strong>sumerheating systems <strong>on</strong> primary energy efficiency in DHsystems including producti<strong>on</strong> plants, especially CHP.ACKNOWLEDGEMENTThis work is part of the Primary Energy Efficiencyproject of Nordic Energy Research.NOMECLATUREAbbreviati<strong>on</strong>sCHPDHDHWDOTHEXVariablesCombined heat <strong>and</strong> power stati<strong>on</strong><strong>District</strong> heatingDomestic hot waterDesign outdoor temperatureHeat exchanger (DH substati<strong>on</strong>)α Heat transfercoefficient (W/m 2. K)β coefficient ofexpansi<strong>on</strong> (K-1)δ Thickness (m)λ C<strong>on</strong>ductivity (W/m . K)Gr Grashof number (-)h Height (m)k Heat transfercoefficient (W/m 2. K)L Length (m)ε Emissisivity (-) m mass flow (kg/s)ν Kinematic viscosity(m 2 /s)ζ Stephan-Boltzmanc<strong>on</strong>stantΔθ Logarithmic meantemperaturedifference (K)A Area (m 2 )Nu Nusselt number (-)P Electric power (W orkW)Pr Pr<strong>and</strong>tl number (-)Q Heat output (W or kW)c p Heat capacity (J/kgK) Ra Rayleigh number (-)C C<strong>on</strong>stant Re Reynolds number (-)g Gravity force (N/s 2 ) T Temperature (ºC or K)Subscripts0 Design c<strong>on</strong>diti<strong>on</strong>(without fan)Fan Add-<strong>on</strong>-fan blower inoperati<strong>on</strong>prPrimary (side)Returni indoor rad radiati<strong>on</strong>m Mean rel Relativeout outdoor s Sec<strong>on</strong>dary (side) orSupply29

The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iaREFERENCES[1] Svensk Fjärrvärme, ―<strong>District</strong> heating substati<strong>on</strong>sdesign <strong>and</strong> installati<strong>on</strong>, Technical regulati<strong>on</strong>sF:101‖, The Swedish <strong>District</strong> <strong>Heating</strong> Associati<strong>on</strong>,2008[2] P. Ljunggren, P-O. Johanss<strong>on</strong>, J. Wollerstr<strong>and</strong>,―Optimized space heating system operati<strong>on</strong> with theaim of lowering the primary return temperature‖, inProc. of the 11th <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong><strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>, 2008, Reykjavik[3] http://www.lenhovdaradiatorfabrik.se/display_sub.asp?apid=20, 2010-04-16, Downloaded spreadsheet for calculating heat output.[4] Swedish Energy Agency, 2008, ―Energy Indicators2008, Theme: Renewable energy‖, 2008[5] http://a-energi.jetshop.se/, 20010-04-20[6] EN 15316-4-5:2007, ―<strong>Heating</strong> systems in buildings.Method for calculati<strong>on</strong> of system energyrequirements <strong>and</strong> system efficiencies‖, CEN,Brussels, 2007[7] J. A. Myhren, S. Holmberg, ‖Design c<strong>on</strong>siderati<strong>on</strong>with ventilati<strong>on</strong>-radiators: Comparis<strong>on</strong>s to traditi<strong>on</strong>altwo-panel radiators‖, Energy <strong>and</strong> buildings 41, p.92-100, 2009[8] A. Trüschell, ―Värmesystem med luftvärmare ochradiatorer, En analys av funkti<strong>on</strong> och prest<strong>and</strong>a‖,Licentiate Thesis, Chalmers, Göteborg, 1999[9] S. W. Churchill, ―Correlating equati<strong>on</strong>s for laminar<strong>and</strong> turbulent free c<strong>on</strong>vecti<strong>on</strong> from a vertical plate‖,Int. J. Heat Mass Transfer, Vol. 18, p. 1323-1329,1975[10] J. P. Holman, ―Heat trans fer‖, 9th editi<strong>on</strong>, 2002[11] Discussi<strong>on</strong> with professor B. Sundén, April 2010[12] P. Selinder, H. Walletun, ‖Modell för ändradeförutsättningar i fjärrvärmenät‖, Rapport 2009:50,Svensk Fjärrvärme, 2009[13] S. Werner, FVB Sverige AB, ‖Nytta med svenskfjärrvärmeforskning‖, FoU – orientering 2004:9,Svensk Fjärrvärme, 200430

- Page 1: 12th Inter

- Page 5 and 6: The 12th I

- Page 7 and 8: The 12th I

- Page 10 and 11: The 12th I

- Page 12 and 13: The 12th I

- Page 14 and 15: For the case of parallel buried pip

- Page 16 and 17: The 12th I

- Page 18 and 19: The 12th I

- Page 20 and 21: The 12th I

- Page 22 and 23: The 12th I

- Page 24 and 25: The 12th I

- Page 26 and 27: The 12th I

- Page 28 and 29: The 12th I

- Page 32 and 33: The 12th I

- Page 34 and 35: The 12th I

- Page 36 and 37: The 12th I

- Page 38 and 39: The 12th I

- Page 40 and 41: The 12th I

- Page 42 and 43: The 12th I

- Page 44 and 45: The 12th I

- Page 46 and 47: The 12th I

- Page 48 and 49: The 12th I

- Page 50 and 51: The 12th I

- Page 52 and 53: The 12th I

- Page 54 and 55: The 12th I

- Page 56 and 57: The 12th I

- Page 58 and 59: The 12th I

- Page 60 and 61: The 12th I

- Page 62 and 63: The 12th I

- Page 64 and 65: The 12th I

- Page 66 and 67: The 12th I

- Page 68 and 69: The 12th I

- Page 70 and 71: The 12th I

- Page 72 and 73: The 12th I

- Page 74 and 75: The 12th I

- Page 76 and 77: The 12th I

- Page 78 and 79: The 12th I

- Page 80 and 81:

The 12th I

- Page 82 and 83:

The 12th I

- Page 84 and 85:

The 12th I

- Page 86 and 87:

The 12th I

- Page 88 and 89:

The 12th I

- Page 90 and 91:

The 12th I

- Page 92 and 93:

The 12th I

- Page 94 and 95:

The 12th I

- Page 96 and 97:

The 12th I

- Page 98 and 99:

the street the more shallow the sha

- Page 100 and 101:

The 12th I

- Page 102 and 103:

The 12th I

- Page 104 and 105:

The 12th I

- Page 106 and 107:

The 12th I

- Page 108 and 109:

The 12th I

- Page 110 and 111:

P-1P-4P-9P-7E-5P-14P-8The 1

- Page 112 and 113:

The 12th I

- Page 114 and 115:

The 12th I

- Page 116 and 117:

The 12th I

- Page 118 and 119:

The 12th I

- Page 120 and 121:

The 12th I

- Page 122 and 123:

The 12th I

- Page 124 and 125:

The 12th I

- Page 126 and 127:

The 12th I

- Page 128 and 129:

The 12th I

- Page 130 and 131:

The 12th I

- Page 132 and 133:

The 12th I

- Page 134 and 135:

The 12th I

- Page 136 and 137:

The 12th I

- Page 138 and 139:

to heating costs of 14,5 ct/kWh. Th

- Page 140 and 141:

The 12th I

- Page 142 and 143:

The 12th I

- Page 144 and 145:

The 12th I

- Page 146 and 147:

The 12th I

- Page 148 and 149:

academic access is facilitated as t

- Page 150 and 151:

The 12th I

- Page 152 and 153:

The 12th I

- Page 154 and 155:

The 12th I

- Page 156 and 157:

The 12th I

- Page 158 and 159:

The 12th I

- Page 160 and 161:

The 12th I

- Page 162 and 163:

1. CHP system operation in A2. Ther

- Page 164 and 165:

The 12th I

- Page 166 and 167:

is covered by operating HOB. In oth

- Page 168 and 169:

The 12th I

- Page 170 and 171:

The 12th I

- Page 172 and 173:

The 12th I

- Page 174 and 175:

The 12th I

- Page 176 and 177:

The 12th I

- Page 178 and 179:

The 12th I

- Page 180 and 181:

The 12th I

- Page 182 and 183:

The 12th I

- Page 184 and 185:

The 12th I

- Page 186 and 187:

The 12th I

- Page 188 and 189:

The 12th I

- Page 190 and 191:

The 12th I

- Page 192 and 193:

The 12th I

- Page 194 and 195:

The 12th I

- Page 196 and 197:

produce heat and electricity. Fluct

- Page 198 and 199:

The 12th I

- Page 200 and 201:

The 12th I

- Page 202 and 203:

The 12th I

- Page 204 and 205:

The 12th I

- Page 206 and 207:

The 12th I

- Page 208 and 209:

The 12th I

- Page 210 and 211:

To assure that the temperatures mea

- Page 212 and 213:

The 12th I

- Page 214 and 215:

The 12th I

- Page 216 and 217:

The 12th I

- Page 218 and 219:

The 12th I

- Page 220 and 221:

production and provide for marginal

- Page 222 and 223:

The 12th I

- Page 224 and 225:

The 12th I

- Page 226 and 227:

The 12th I

- Page 228 and 229:

The 12th I

- Page 230 and 231:

The 12th I

- Page 232 and 233:

The 12th I

- Page 234 and 235:

The 12th I

- Page 236 and 237:

The 12th I

- Page 238 and 239:

The 12th I

- Page 240 and 241:

The 12th I

- Page 242 and 243:

In addition, it can also be observe

- Page 244 and 245:

The 12th I

- Page 246 and 247:

owner is normally only interested i

- Page 248 and 249:

The 12th I

- Page 250 and 251:

The 12th I

- Page 252 and 253:

The 12th I

- Page 254 and 255:

The 12th I

- Page 256 and 257:

The 12th I

- Page 258 and 259:

The 12th I

- Page 260 and 261:

The 12th I

- Page 262 and 263:

The 12th I

- Page 264 and 265:

The 12th I

- Page 266 and 267:

The 12th I

- Page 268 and 269:

The 12th I

- Page 270 and 271:

The 12th I

- Page 272 and 273:

The 12th I

- Page 274 and 275:

The 12th I

- Page 276 and 277:

The 12th I

- Page 278 and 279:

The 12th I

- Page 280 and 281:

The 12th I

- Page 282 and 283:

The 12th I

- Page 284 and 285:

The 12th I

- Page 286 and 287:

The 12th I

- Page 288 and 289:

The 12th I

- Page 290 and 291:

Stockholm district heating system a

- Page 292 and 293:

The 12th I

- Page 294 and 295:

The 12th I

- Page 296 and 297:

The 12th I

- Page 298 and 299:

The 12th I

- Page 300 and 301:

The 12th I

- Page 302 and 303:

The 12th I

- Page 304 and 305:

The 12th I

- Page 306 and 307:

The 12th I

- Page 308 and 309:

The 12th I

- Page 310 and 311:

The 12th I

- Page 312 and 313:

The 12th I

- Page 314 and 315:

The values presented do of course l

- Page 316 and 317:

The 12th I

- Page 318 and 319:

The 12th I

- Page 320 and 321:

The 12th I

- Page 322 and 323:

The 12th I

- Page 324 and 325:

The 12th I

- Page 326:

The 12th I